Split type bearing saddle for wagon bogie

A technology for railway wagons and bogies, which is applied in the direction of the device for lateral relative movement between the underframe and the bogie, and can solve the problems of increasing the side frame, the maintenance amount of the load bearing saddle, the poor reliability of the parts, and the impact, so as to improve the reliability Maintainability, simple split structure, and economical improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is specifically described below by way of embodiment, and present embodiment is only used to further illustrate the present invention, but can not be interpreted as the restriction to protection scope of the present invention, some non-compliances that those skilled in the art make according to the content of the present invention above-mentioned Essential improvements and adjustments also belong to the protection scope of the present invention.

[0019] combine Figure 1 to Figure 3 .

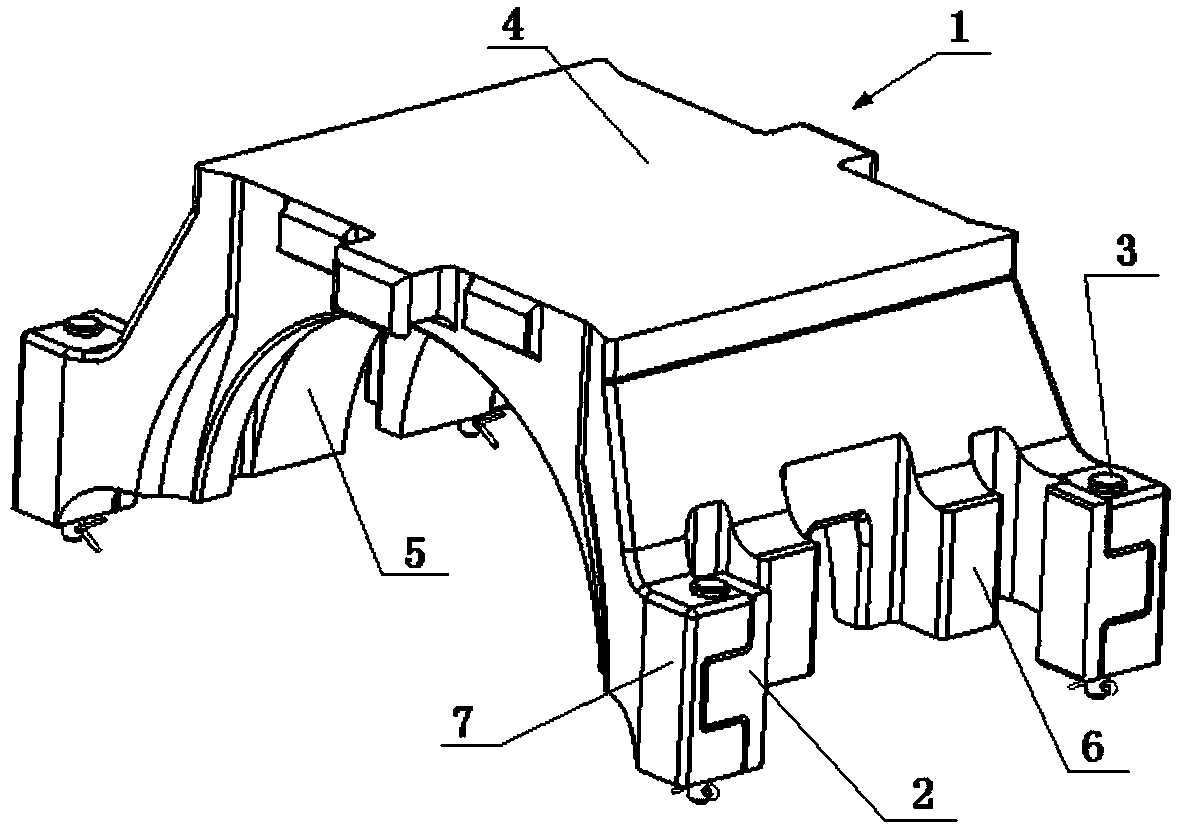

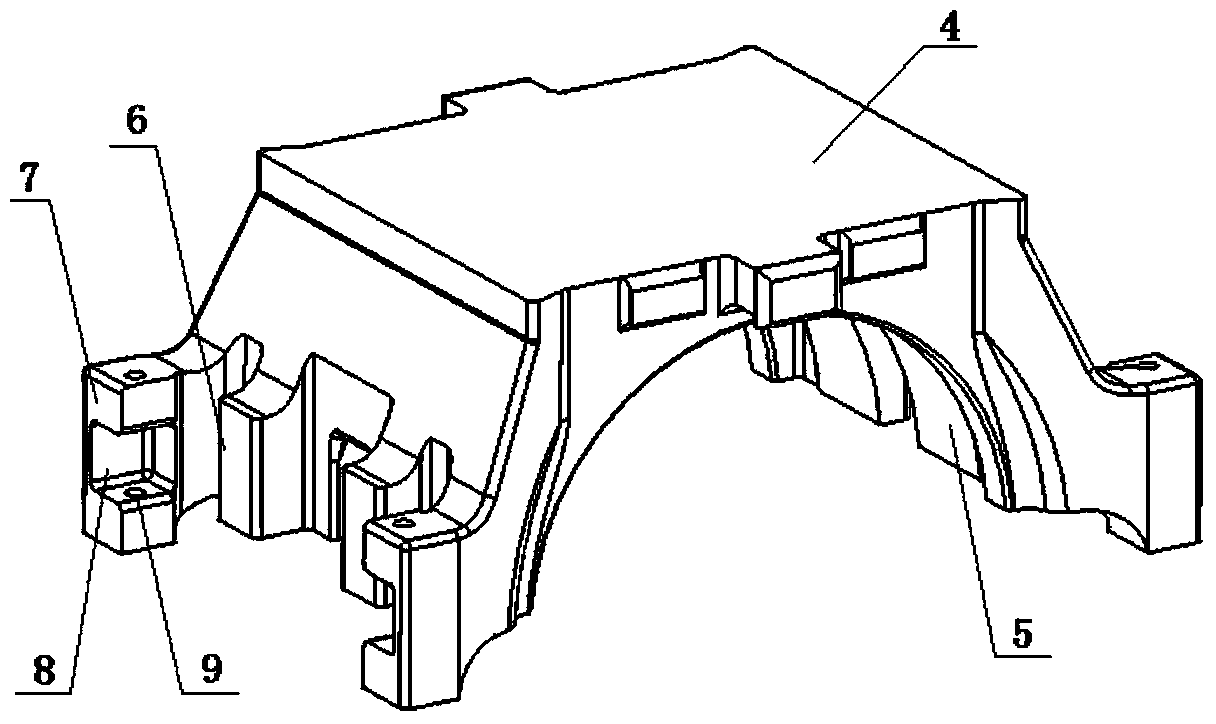

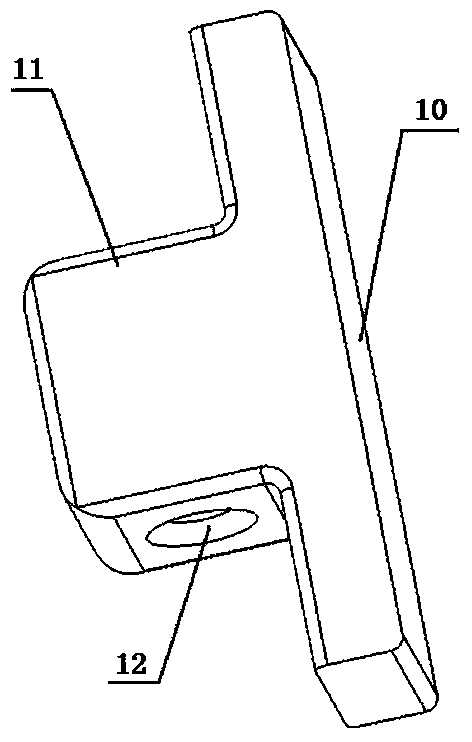

[0020] As shown in the figure, the railway freight car bogie uses a split bearing saddle. The bearing saddle 1 is installed in the pedestal frame of the side frame, including the top 4, the saddle part 5, the longitudinal stop 6 and the transverse stop 7. The removable wear plate 2 is attached via a round pin 3 .

[0021] There is a transverse positioning groove 8 in the middle of the direction in which the transverse stopper 7 is matched with the side frame, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com