Motor trolley for spinning

A trolley and motorized technology, applied in the field of textile motorized trolleys, can solve the problems of slow travel, laborious transportation workers, weight of the trolley, and limitation of manpower durability, and achieves the effect of preventing falling and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be further described in detail below.

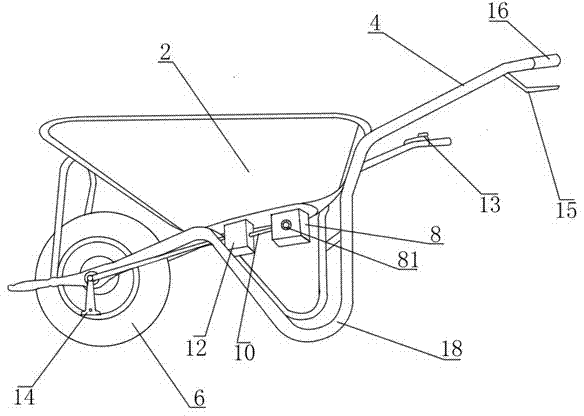

[0015] like figure 1 As shown, a kind of textile motor cart of the present invention includes a car body 2, a push handle 4 and a driving wheel 6, and also includes: a power device 8, a transmission system 12 and a braking system 14. The power equipment 8 is installed on the rear end of the chassis of the car body. The power equipment 8 is also provided with a power equipment controller 81 . The power equipment controller 81 controls the opening and closing of the power equipment 8 . Speed change system 12 is installed on car body chassis, and speed change system 12 keeps relative position with power equipment 8, and push handle 4 ends are push handle 16, and speed change controller 13 is installed on push handle 16, and speed change controller 13 controls speed change system 12. Braking system 14 is installed on driving wheel 6, and brake lever 15 is installed on push handle 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com