Feeding device of color testing machine

A technology of feeding device and color testing machine, which is applied in the field of color testing machines, can solve problems such as test cup temperature imbalance, influence on color test quality, and changes in working conditions, achieve uniform speed, stabilize color test quality, and prevent excessive feeding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

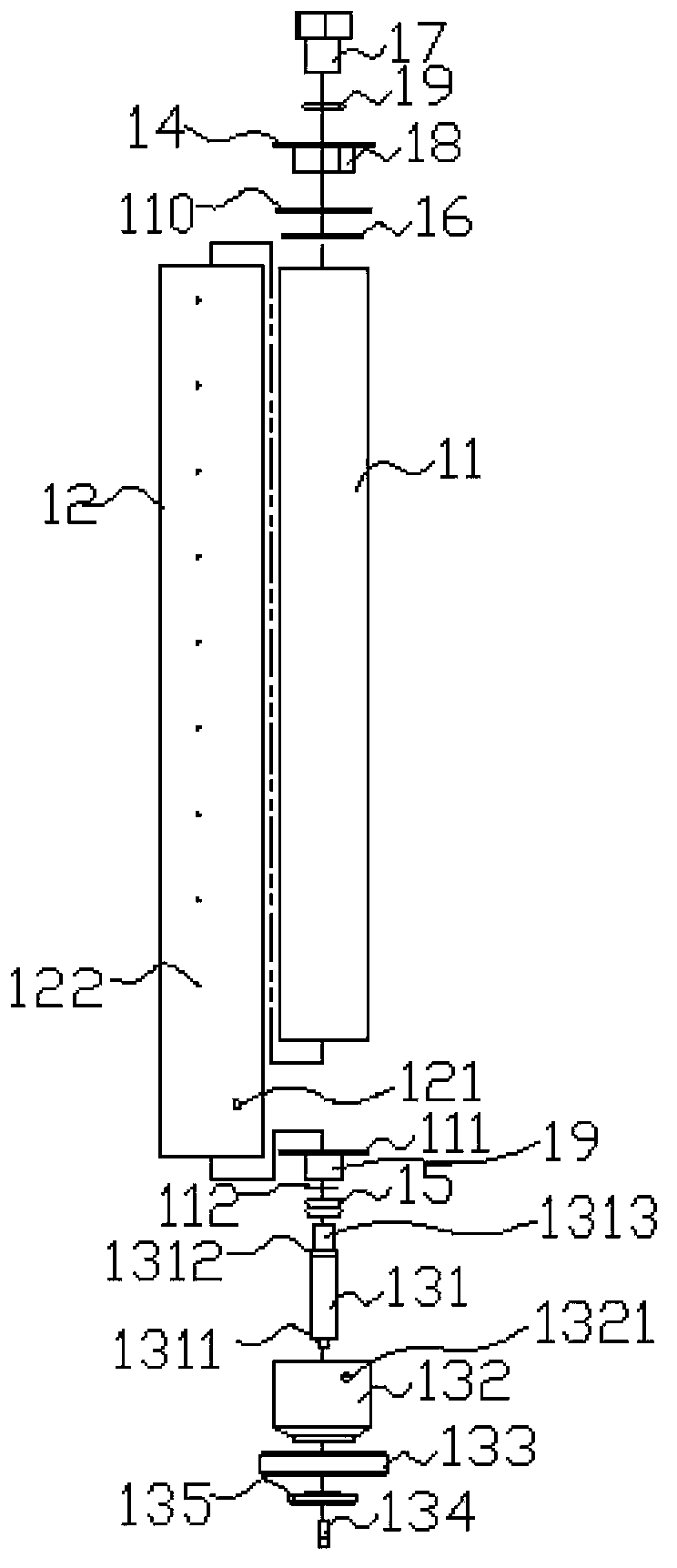

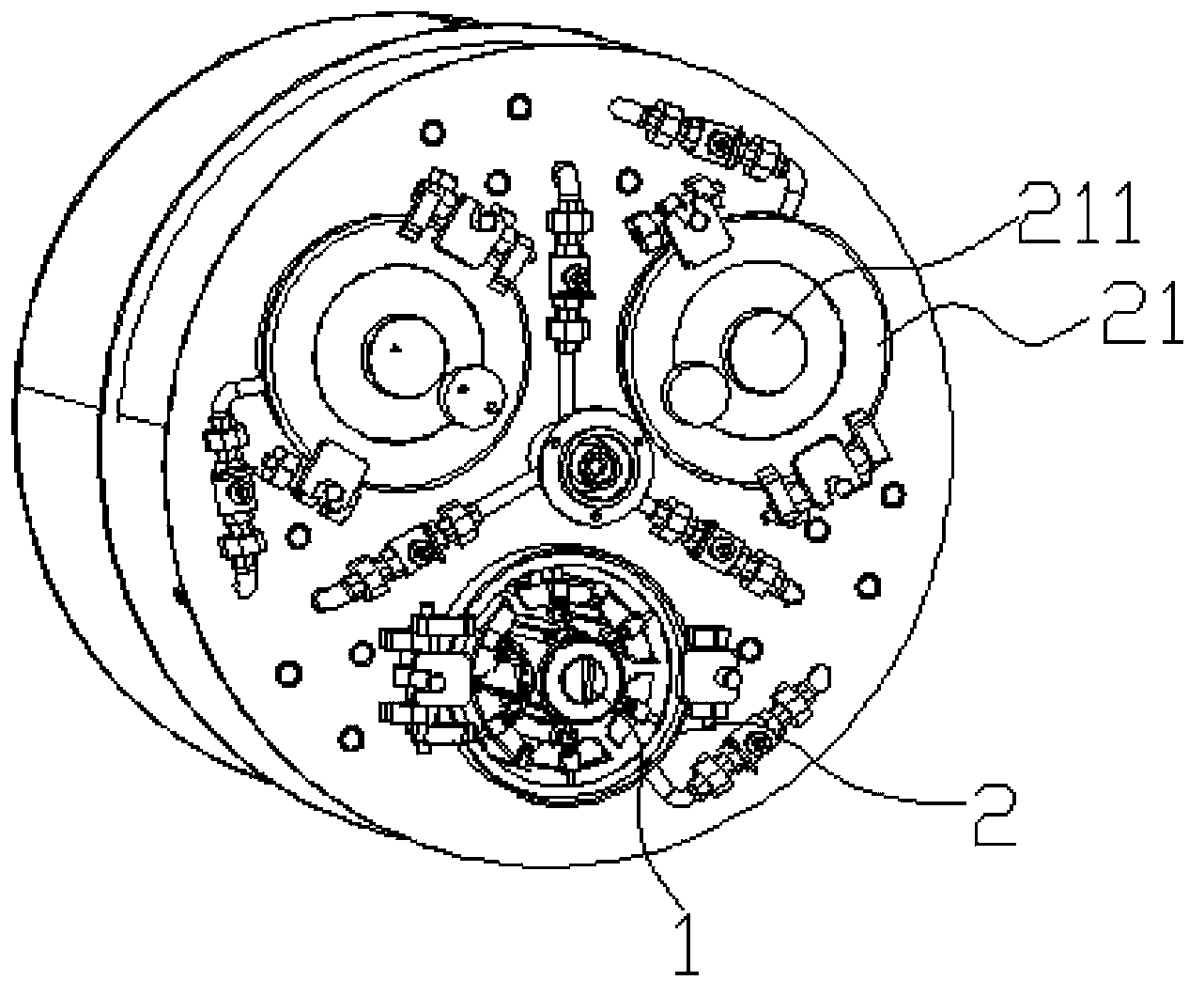

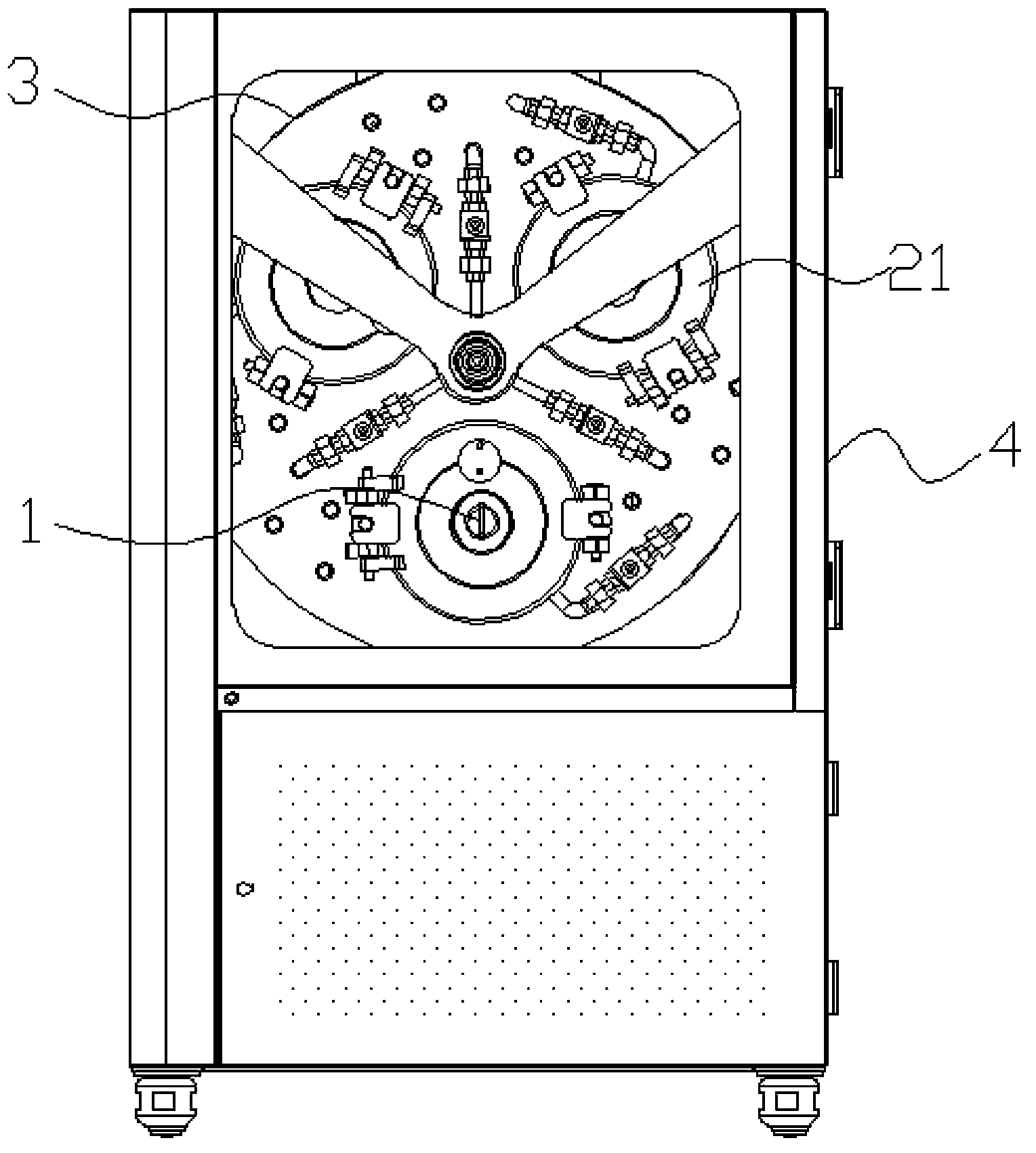

[0015] Such as Figure 1-2 As shown, the feeding device 1 of the color tester of the present invention is installed in the test cup 2 . The test cup 2 is installed in the cylinder 3, and the cylinder 3 is installed in the color tester 4. The feeding device 1 includes an inner cylinder 11, an outer cylinder 12 and an adjustment device. The outer cylinder 12 is a hollow body, one end of the outer cylinder 12 is an adjustment end, and the other end is a closed end. The adjustment device is located at the adjustment end of the outer cylinder 12 . A plurality of holes 122 are formed at intervals through the side wall of the outer cylinder 12 . The inner cylinder 11 is a hollow body, one end of the inner cylinder 11 is an open end, and the other end is a closed end. The inner cylinder 11 is movably disposed in the outer cylinder 12 through the adjustment device 13 , the closed end of the inner cylinder 11 faces the adjustment end of the outer cylinder 12 , and the open end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com