Deck-type triangular truss steel joist bond beam

A technology of triangular truss and combined beams, applied in the field of steel truss girder bridges, can solve problems such as affecting the overall appearance, many rods and nodes, and manufacturing costs, etc., and achieve the effects of enhancing aesthetics, overcoming fatigue stress, and being simple in force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] Example: a top-supporting triangular truss steel truss combined beam

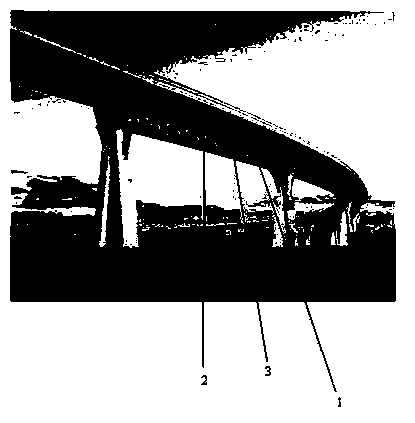

[0031] The bridge is a top-supporting steel-concrete composite beam with a span of 60m+72m+60m and a triangular cross-section. The main beam adopts a single steel pipe concrete structure 1, and the web 3 is connected with the bridge deck concrete slab 1 to form a stress system. , and the effect diagram composed of bridge piers and bridge decks, etc., see figure 1 .

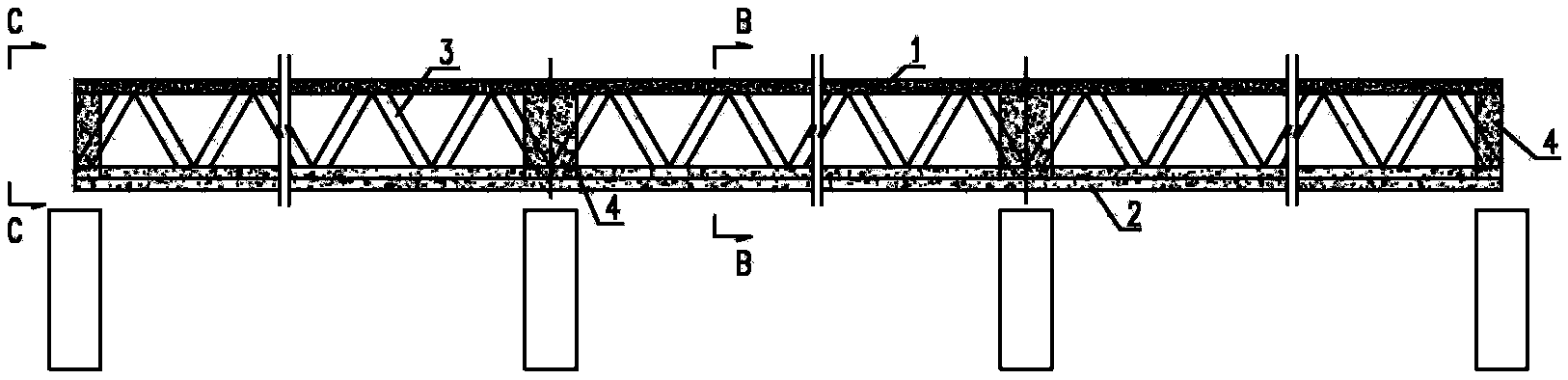

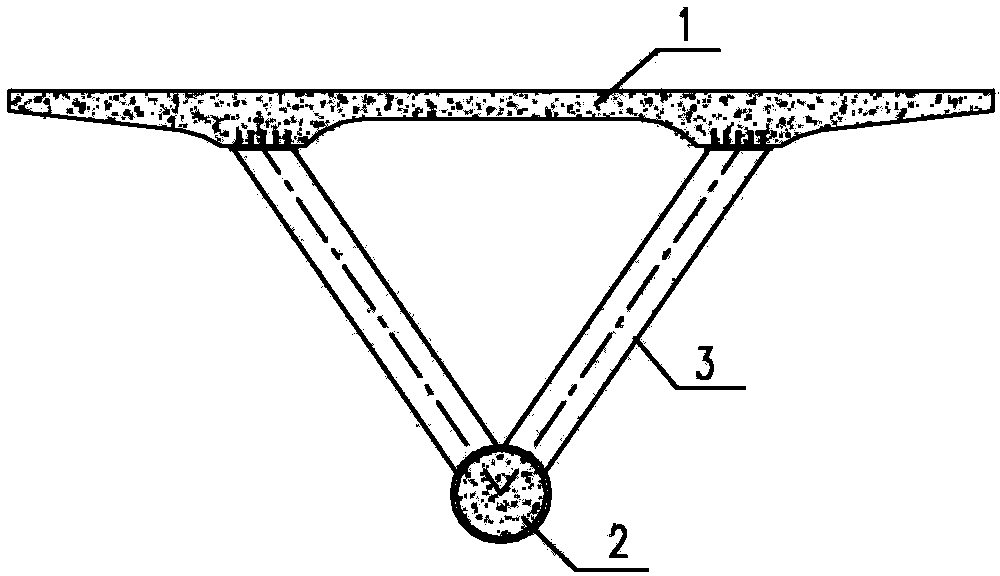

[0032] The elevation view of the steel truss composite beam in the top-supported triangular truss (see figure 2 ), it can be seen that the top-supported triangular truss steel truss combined beam is composed of concrete deck 1, web 3, and lower chord 2, the lower chord and the web are connected by a gusset plate, the lower chord is a steel tube concrete structure, and the diameter of the steel tube The wall thickness of the steel pipe is 1.2m, the wall thickness of the steel pipe is 0.04m, concrete is poured into the steel pipe, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com