Method for fixing electric pole ends without releasing partial prestress

A fixing method and prestressing technology, which is applied in the direction of building types, buildings, towers, etc., can solve the problems of not being able to fully utilize the prestressing of low-relaxation spiral rib steel wires, and achieve the effects of ensuring safe power supply, increasing service life, and preventing falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make it easy to understand the technical means, creative features, work flow, and use methods of the present invention to achieve the purpose and effect, the present invention will be further elaborated below.

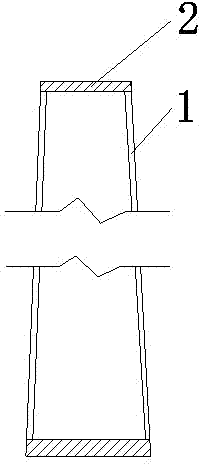

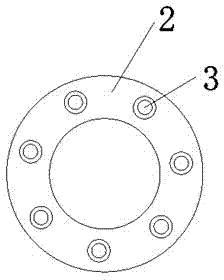

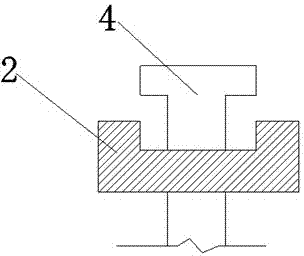

[0013] Such as Figure 1-3 As shown, a method for fixing the end of a prestressed electric pole without tension, comprising the following steps: prefabricating a concrete pole body 1, installing a corrosion-resistant pole end 2, installing and fixing a low-relaxation spiral rib steel wire 4, the concrete pole body 1 The diameter of the upper port is smaller than the diameter of the lower port. The upper and lower ends of the concrete rod body 1 are equipped with corrosion-resistant pole ends 2. The corrosion-resistant pole ends 2 are fixed to the concrete rod body 1 through low-relaxation spiral rib steel wires 4 to ensure better prestressing. play an effect.

[0014] The low-relaxation spiral rib steel wire 4 is a T-shaped low-relaxation spiral rib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com