Scroll expander

An expander and scroll technology, applied in the field of scroll expanders, can solve problems such as deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

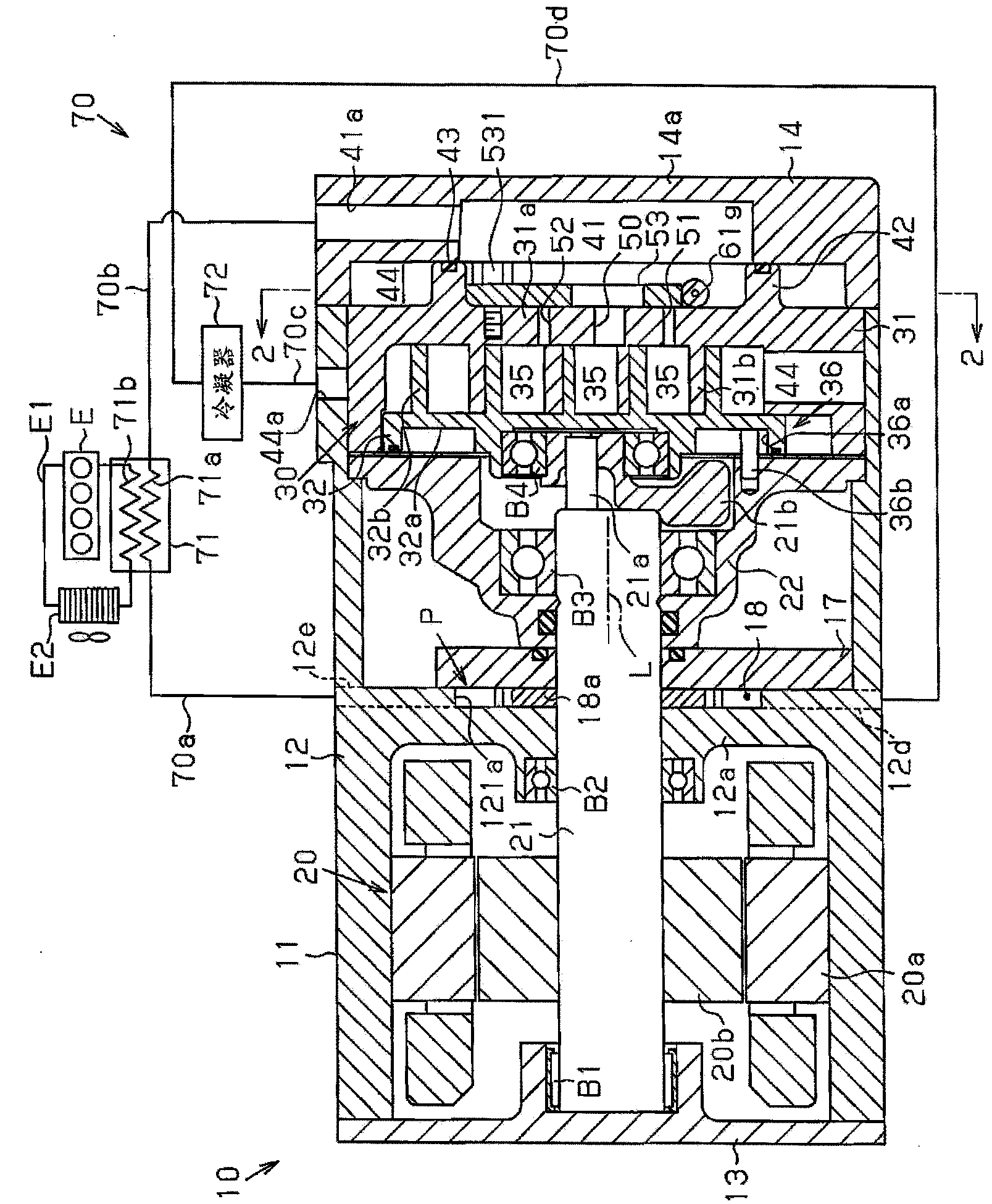

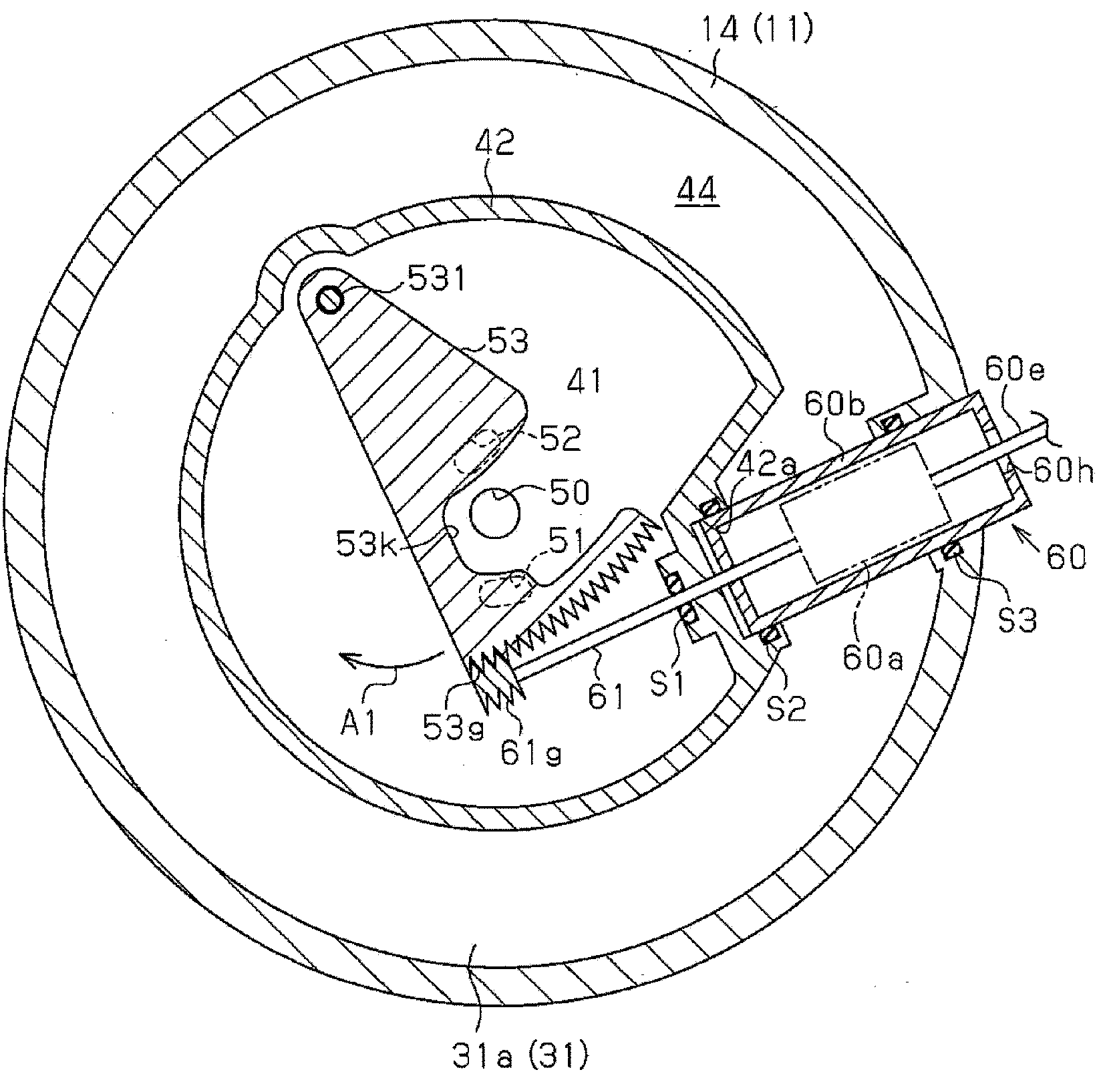

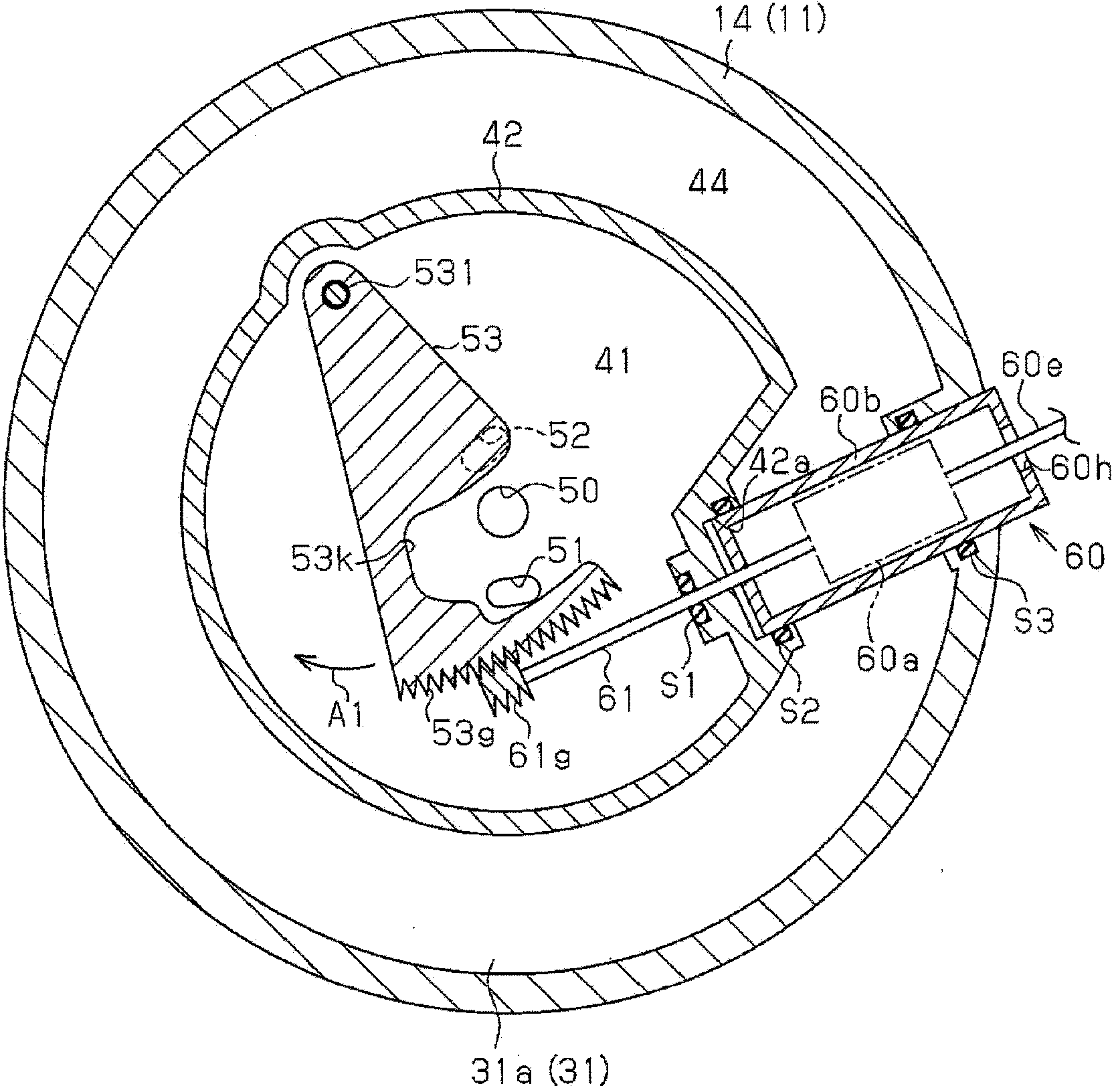

[0019] In the following, reference will be made to Figure 1 to Figure 4 A complex fluid machine 10 to be installed in a Rankine cycle system 70 according to one embodiment of the present invention is described.

[0020] Such as figure 1 As shown, the complex fluid machine 10 includes a housing 11 . The housing 11 is composed of a cylindrical central housing member 12, a plate-shaped front housing member 13, and a rear housing member 14, wherein the plate-shaped front housing member 13 is connected to one end of the central housing member 12, and the rear housing member 14 is The housing member 14 is shaped as a tube having a closed end connected to the other end of the central housing member 12 . A partition wall 12 a is formed on the inner peripheral surface of the center case member 12 . The motor generator 20 is housed in a space defined by the inner peripheral surface of the center case member 12 , the partition wall 12 a , and the front case member 13 . The motor ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com