Control gear of automatic gearbox

A technology of automatic transmission and control device, applied in transmission, fluid transmission, transmission control, etc., can solve problems such as difficulty in suppressing lock-up clutch slippage, high oil pressure, abnormal noise, etc., to prevent the generation of abnormal noise, The effect of suppressing slippage and preventing abnormal noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

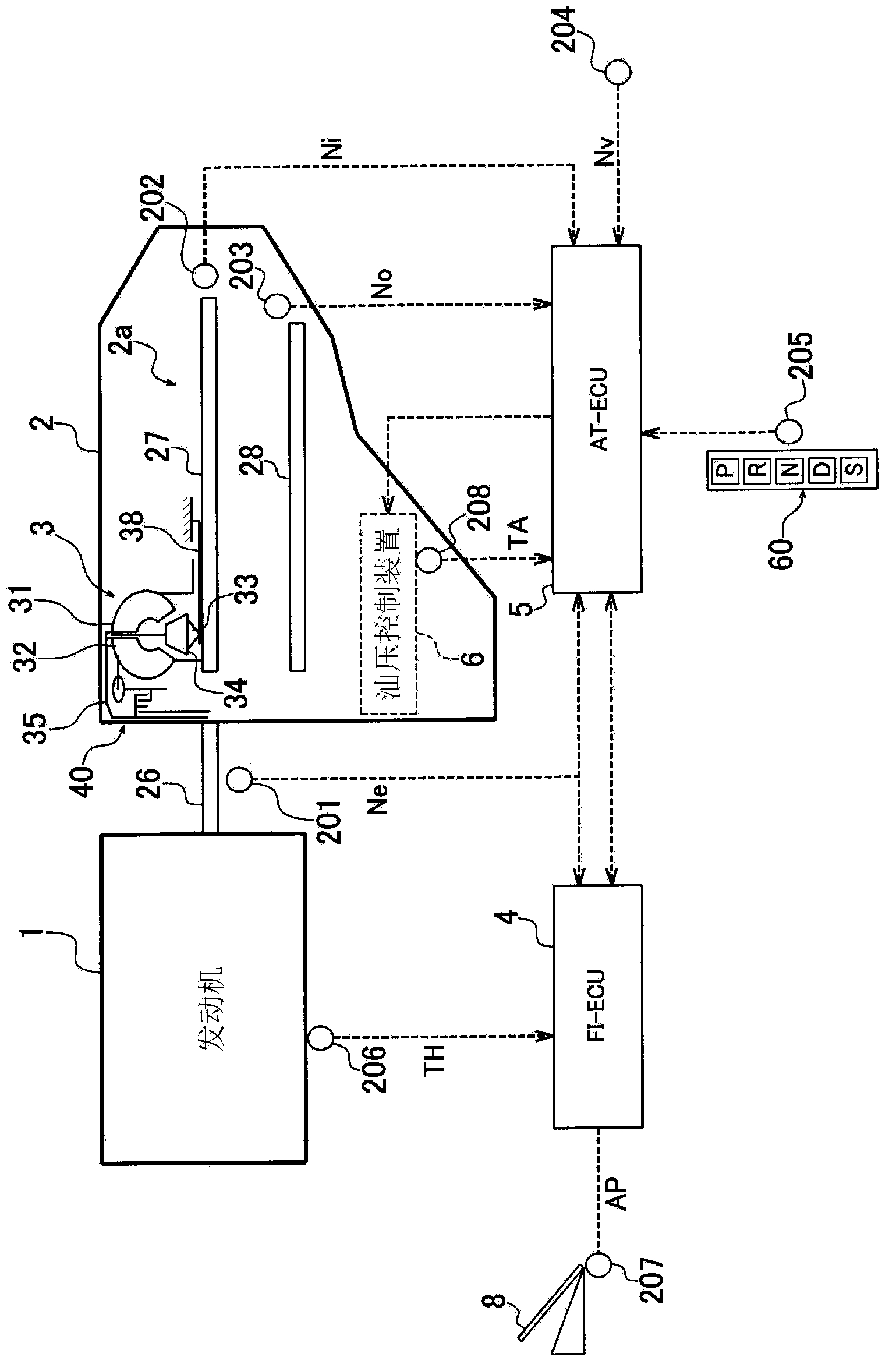

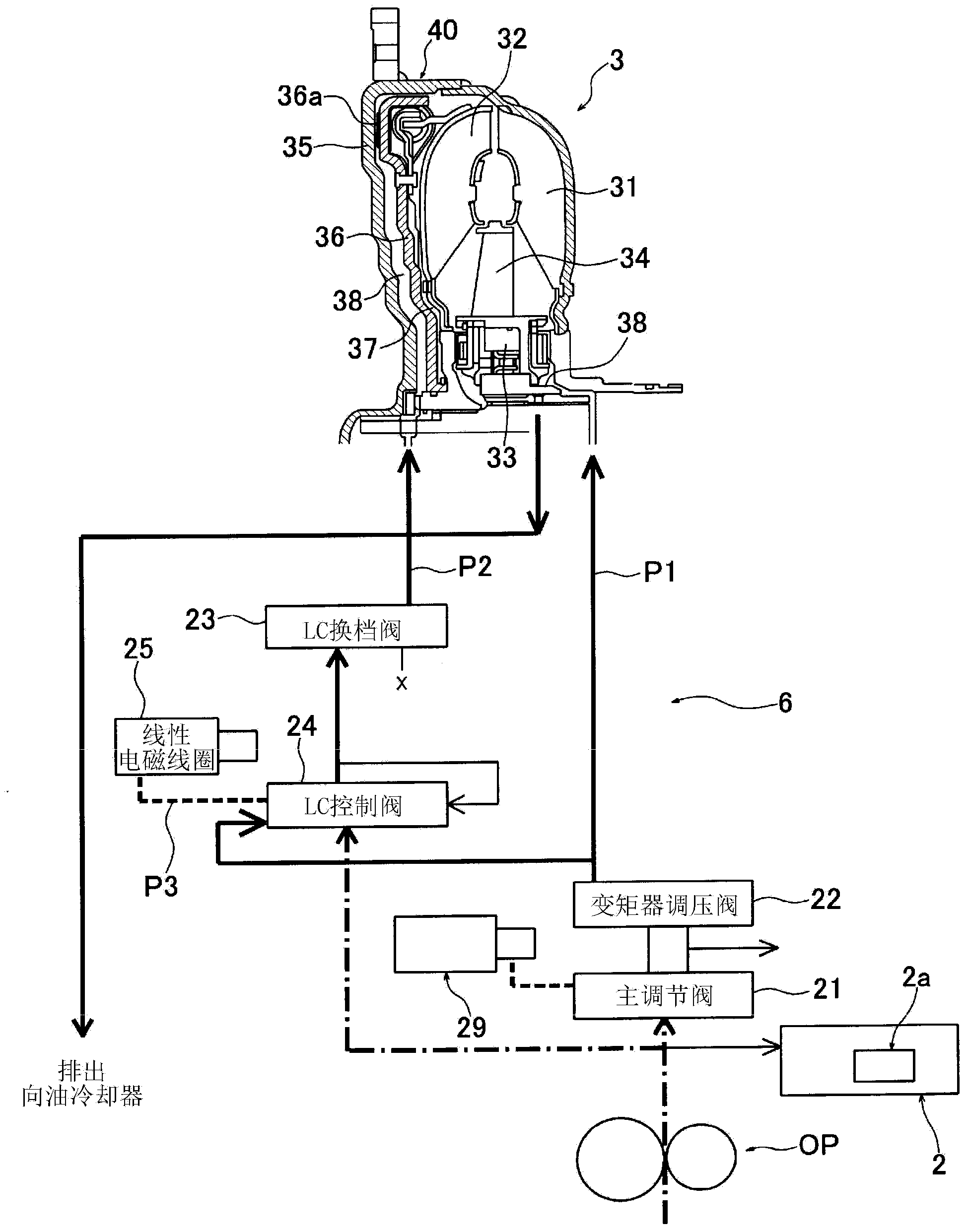

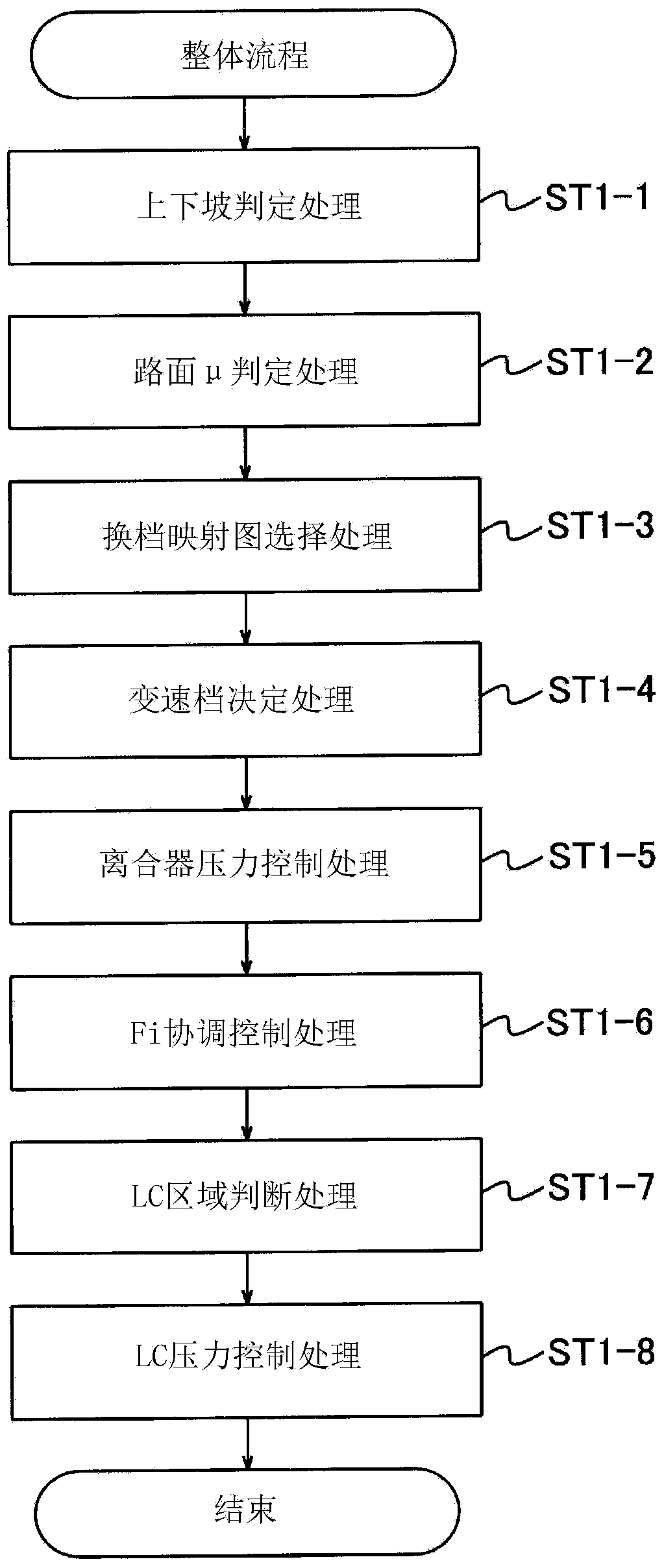

[0027] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. figure 1 It is a schematic diagram of a drive system of a vehicle provided with a control device for an automatic transmission according to an embodiment of the present invention. also, figure 2 It is a diagram showing a torque converter 3 and a hydraulic control device (hydraulic circuit) 6 which will be described later. Such as figure 1As shown, the vehicle of this embodiment has an engine 1 and an automatic transmission 2 coupled to the engine 1 via a fluid torque converter 3 . The automatic transmission 2 has a stepped transmission mechanism 2 a with multiple gears (for example, 6 forward speeds / 1st reverse speed). In addition, this vehicle has: FI-ECU 4 which controls engine 1; AT-ECU (control unit) 5 which controls automatic transmission 2 including torque converter 3; Rotational drive, engagement control of the lock-up clutch 40 described later, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com