Multi-channel gasification bio-particle combustion engine and work method thereof

A biological particle and burner technology, which is used in combustion equipment, solid fuel combustion, lighting and heating equipment, etc., can solve the problems of low efficiency, inconvenience, and inability to clean the internal gasification chamber, and achieve good cleaning effect and improve The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

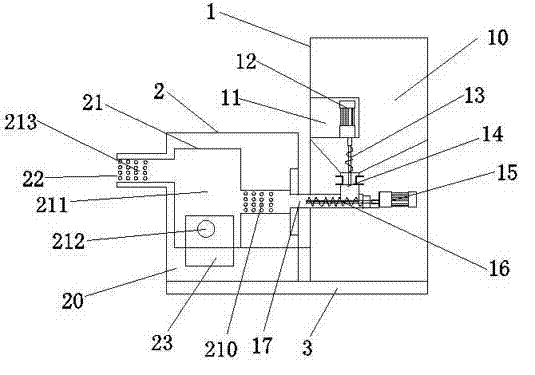

[0018] refer to figure 1 As shown, a multi-channel gasification biological particle burner includes a particle combustion box 2, a charging box 1 connected to the particle combustion box 2, and a base 3 arranged under the particle combustion box 2 and the charging box 1; The charging box 1 includes a storage hopper 10, a first motor protection case 11 disposed in the storage hopper 10, a first motor 12 disposed in the first motor protection case 11, and a first motor 12 connected at one end to the first motor 12. Screw rod 13, and the first feed pipe 14 that links to each other with storage hopper 10 ends, and the second motor 15 that is arranged on the first feed pipe 14 below, and the second screw rod 16 that one end links to each other with second motor 15, and one end connects with the second motor 15 A feed pipe 14 communicates with the second feed pipe 17; the particle combustion box 2 includes a combustion box outer chamber 20, and a combustion box inner chamber 21 arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com