Magnetic shoe structure of direct-current micromotor

A micro-motor and magnetic tile technology, applied in the shape/style/structure of the magnetic circuit, static components of the magnetic circuit, etc., can solve the problems of difficult to meet environmental protection requirements, low load speed, large load current, etc., and achieve small current rise, The effect of reducing the influence of magnetic field and good product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

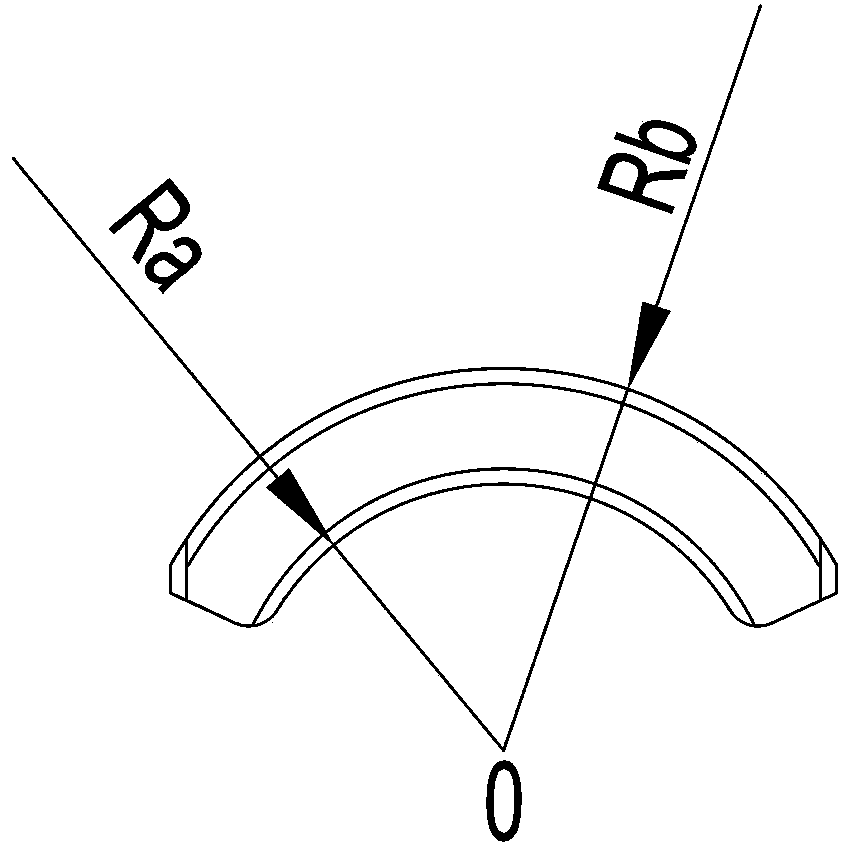

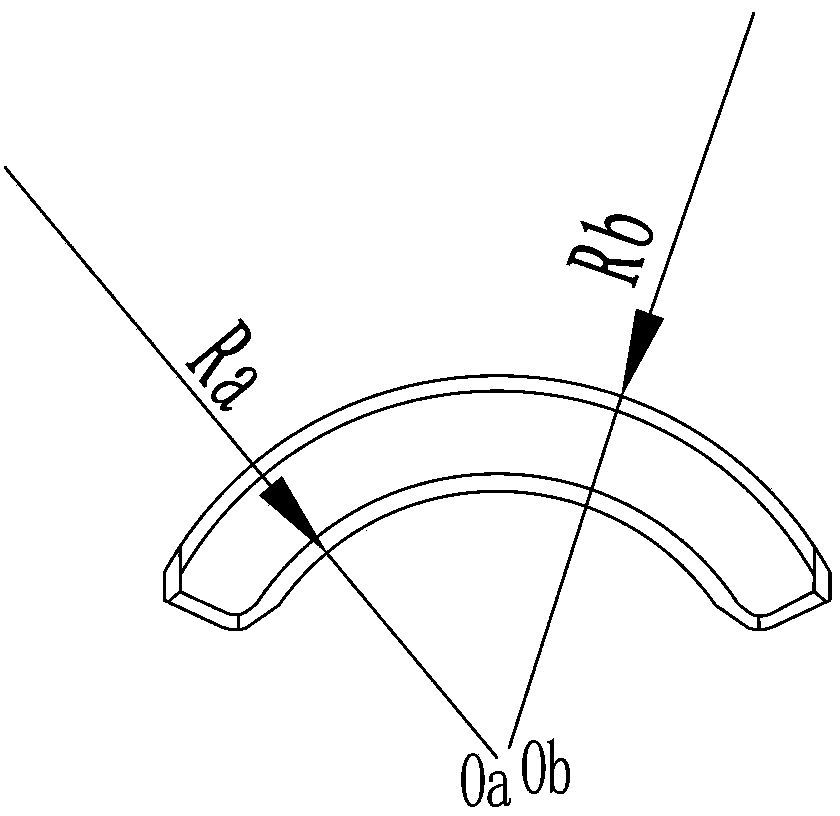

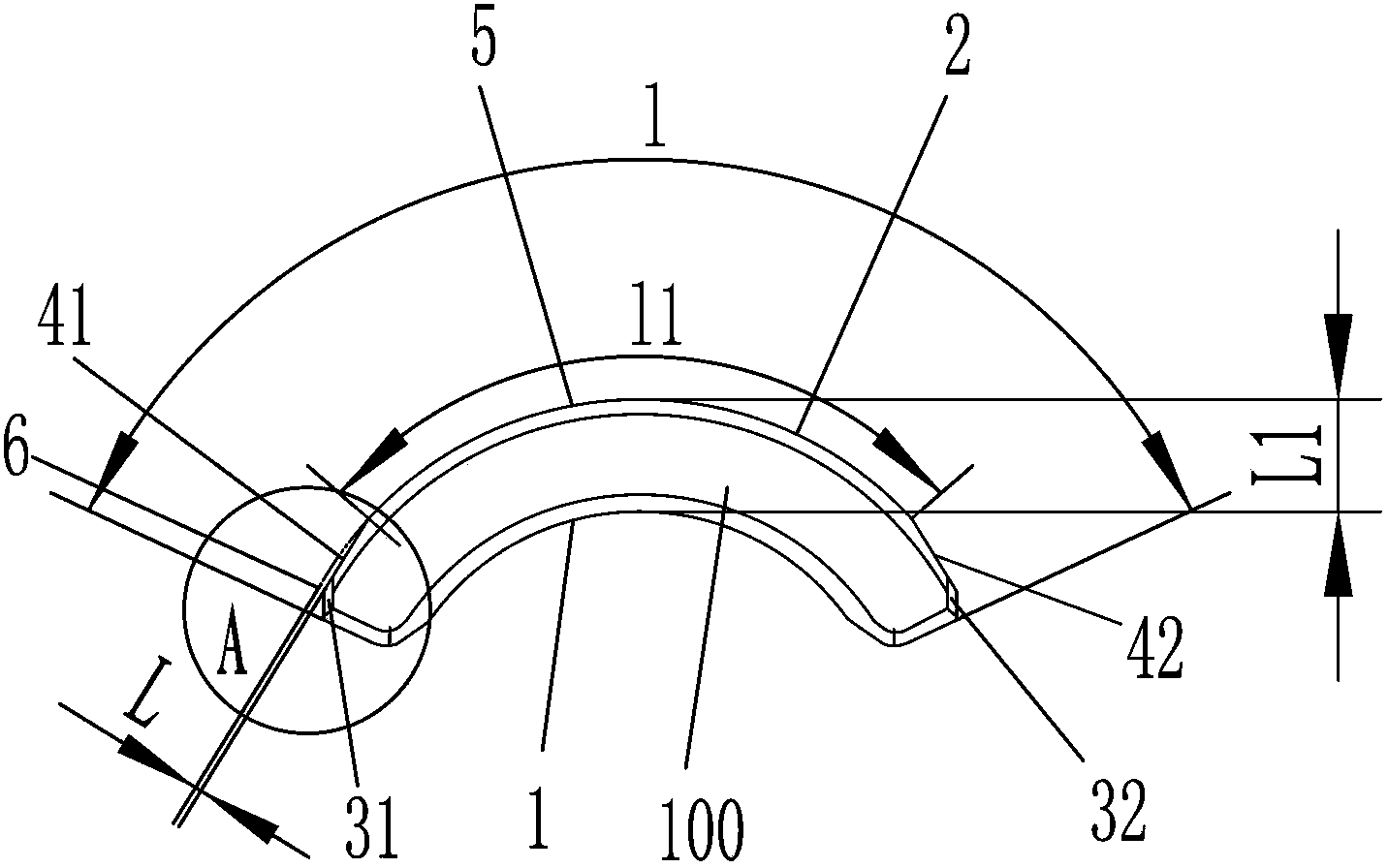

[0021] Such as Figure 3 to Figure 6 The magnetic tile structure of a DC micro-motor shown in , includes a magnetic tile body 100, the inner arc surface 1 and the outer arc surface 2 of the magnetic tile body 100 are concentric, and the two ends of the outer arc surface 2 respectively have an R angle 31 , 32, respectively along the inner ends of the two R angles facing inwardly, a flat cut surface 41, 42 is provided on the outer arc surface, and the two flat cut surfaces 41, 42 are symmetrical to each other. There is a distance between the tangent surfaces 41, 42 and the extension surface 6 of the arc surface 5 in the middle of the outer arc surface, wherein the vertical distance L between the outer end point of the tangent surface and the extension surface 6 is the distance between the outer arc surface 2 and the extension surface 6....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com