Subsoil compaction device of rice precision seedling seeding machine

A compacting device and seeder technology, which is applied in compactors, agricultural machinery and implements, applications, etc., can solve the problems of inaccurate guarantees and just pressing, and achieve reliable work, high efficiency, and broad market application and promotion foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

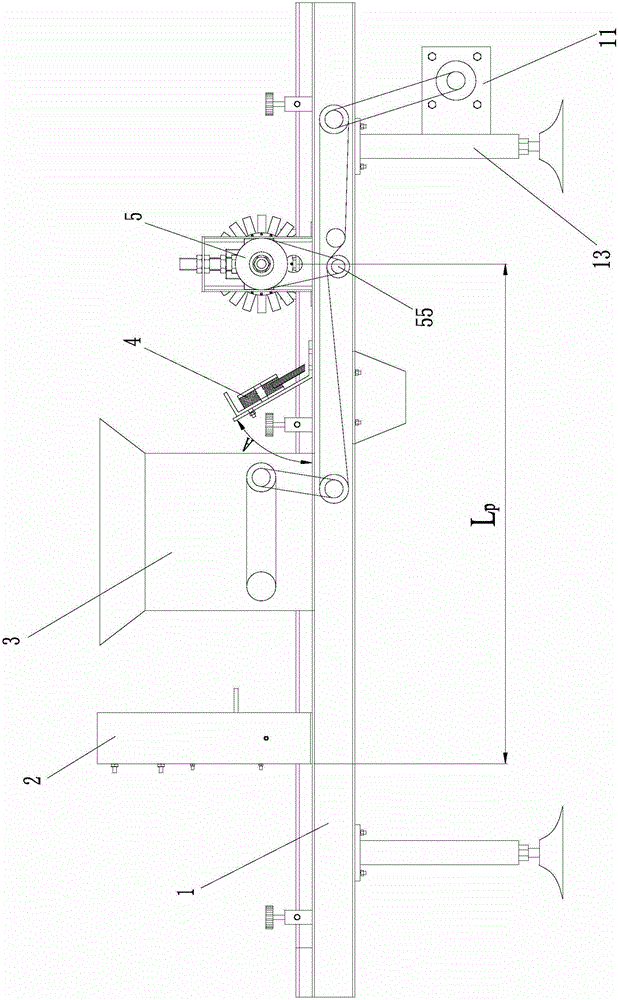

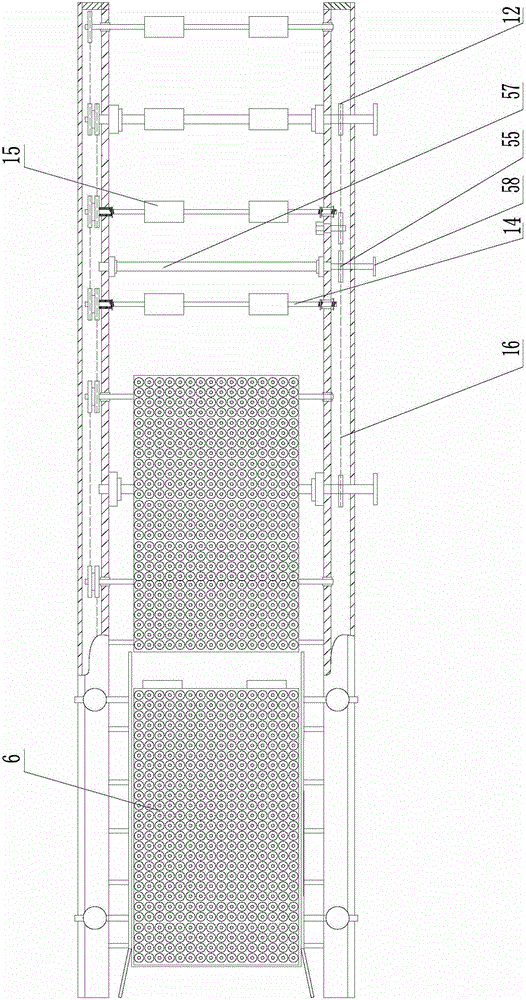

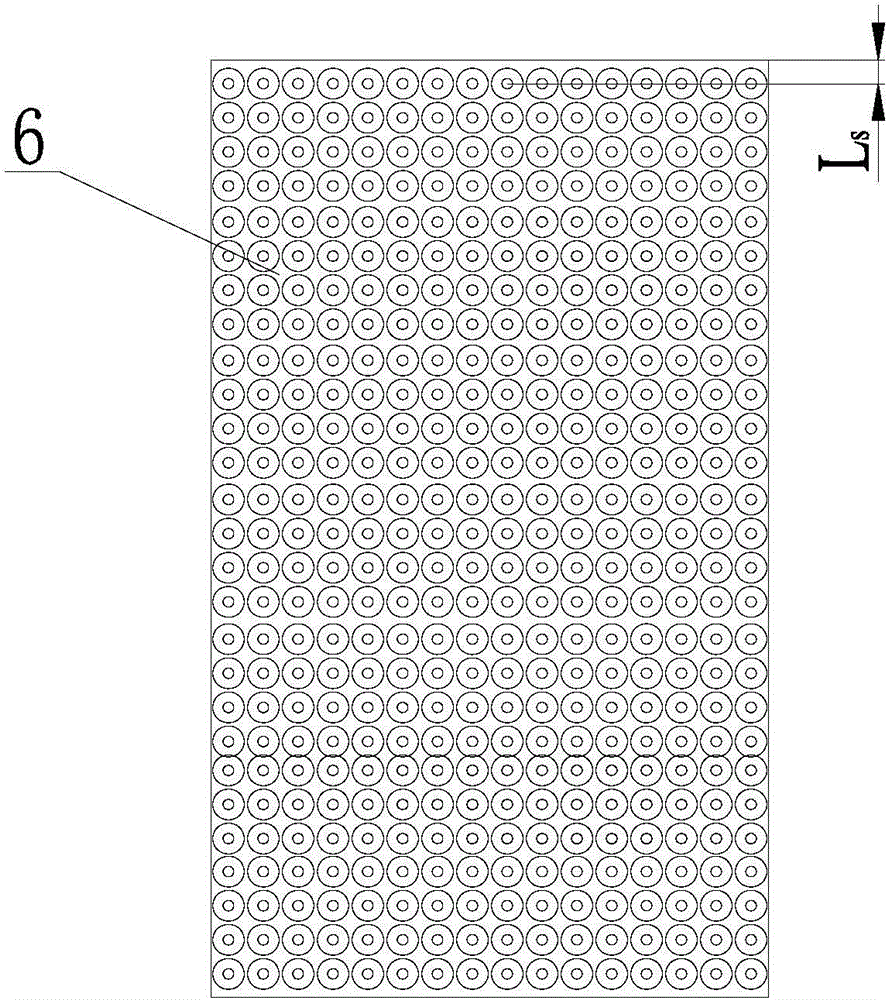

[0048] Such as figure 1 As shown, a subsoil compaction device of a rice precision seedling seeding machine includes a frame 1, a hole alignment mechanism 2 sequentially arranged on the frame 1, a subsoil covering mechanism 3, a soil sweeping mechanism 4, and a subsoil compaction mechanism 5;

[0049] The frame 1 is provided with a drive motor 11, a seedling tray delivery mechanism 12 with 4 support legs 13, and the support legs 13 are arranged on the frame 1, and the drive motor 11 is connected with the seedling tray delivery mechanism 12; the seedling tray delivery mechanism 12 It includes a transmission chain 16 and a plurality of rotating conveying shafts 14 arranged at equal intervals. The rotating conveying shaft 14 is covered with rubber idlers 15, and the rubber idlers 15 are two, respectively sleeved on the rotating conveying shafts 14. The rotating conveying shafts 14 are all connected with transmission chain 16.

[0050] The hole alignment mechanism 2 includes a limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com