Patents

Literature

43results about How to "Drop in time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

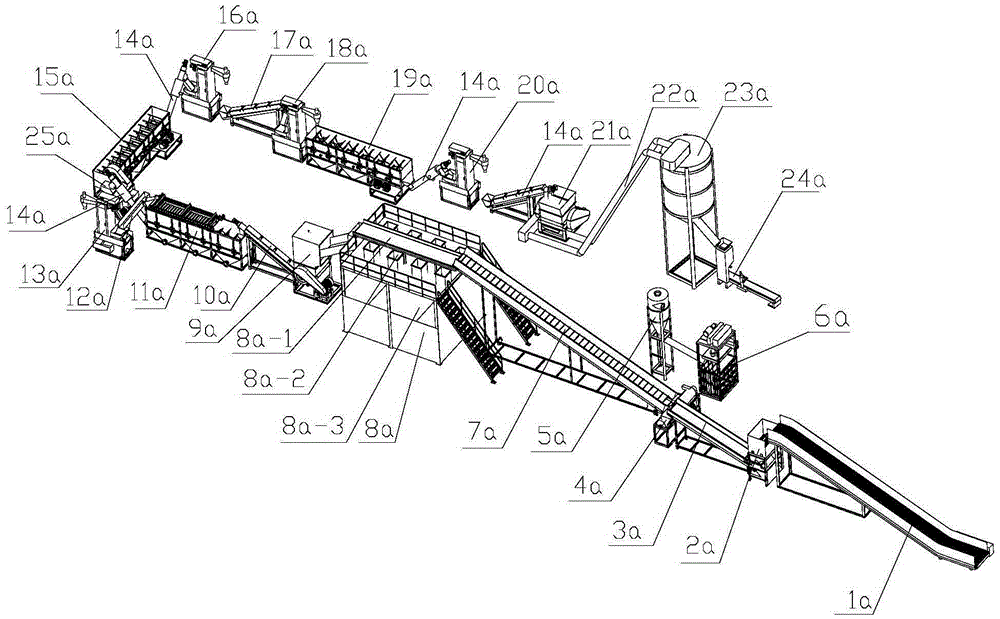

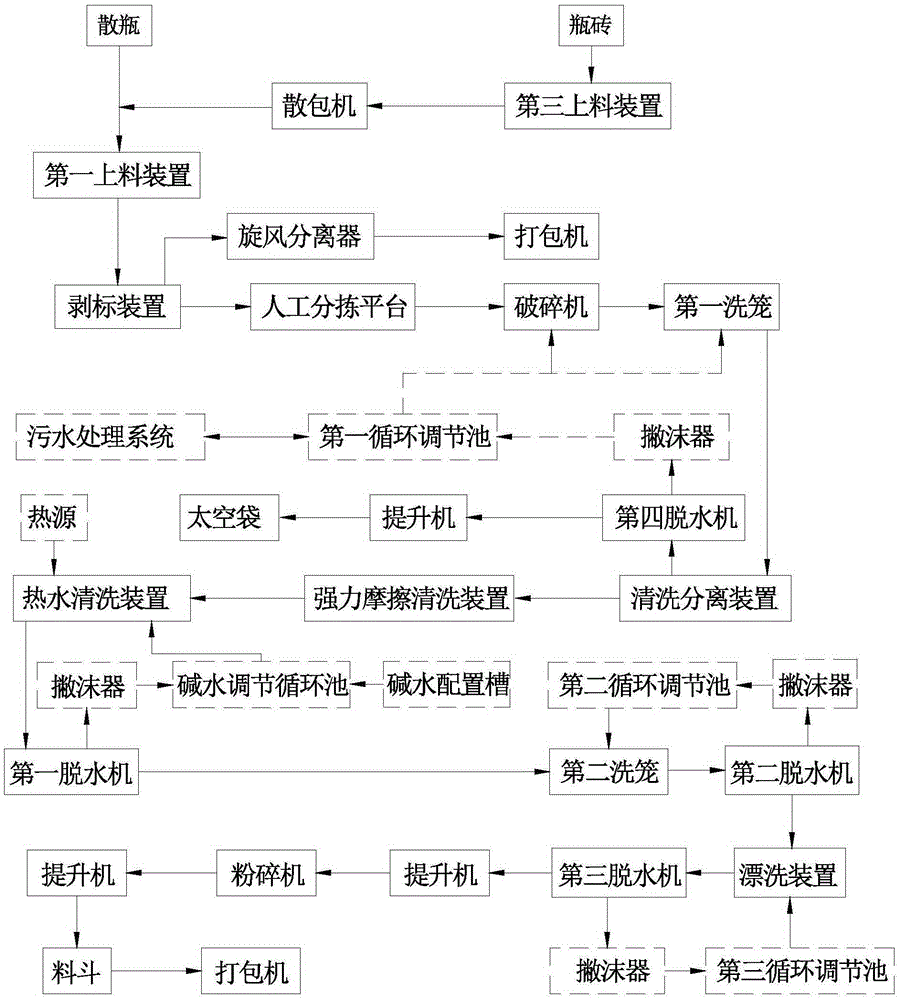

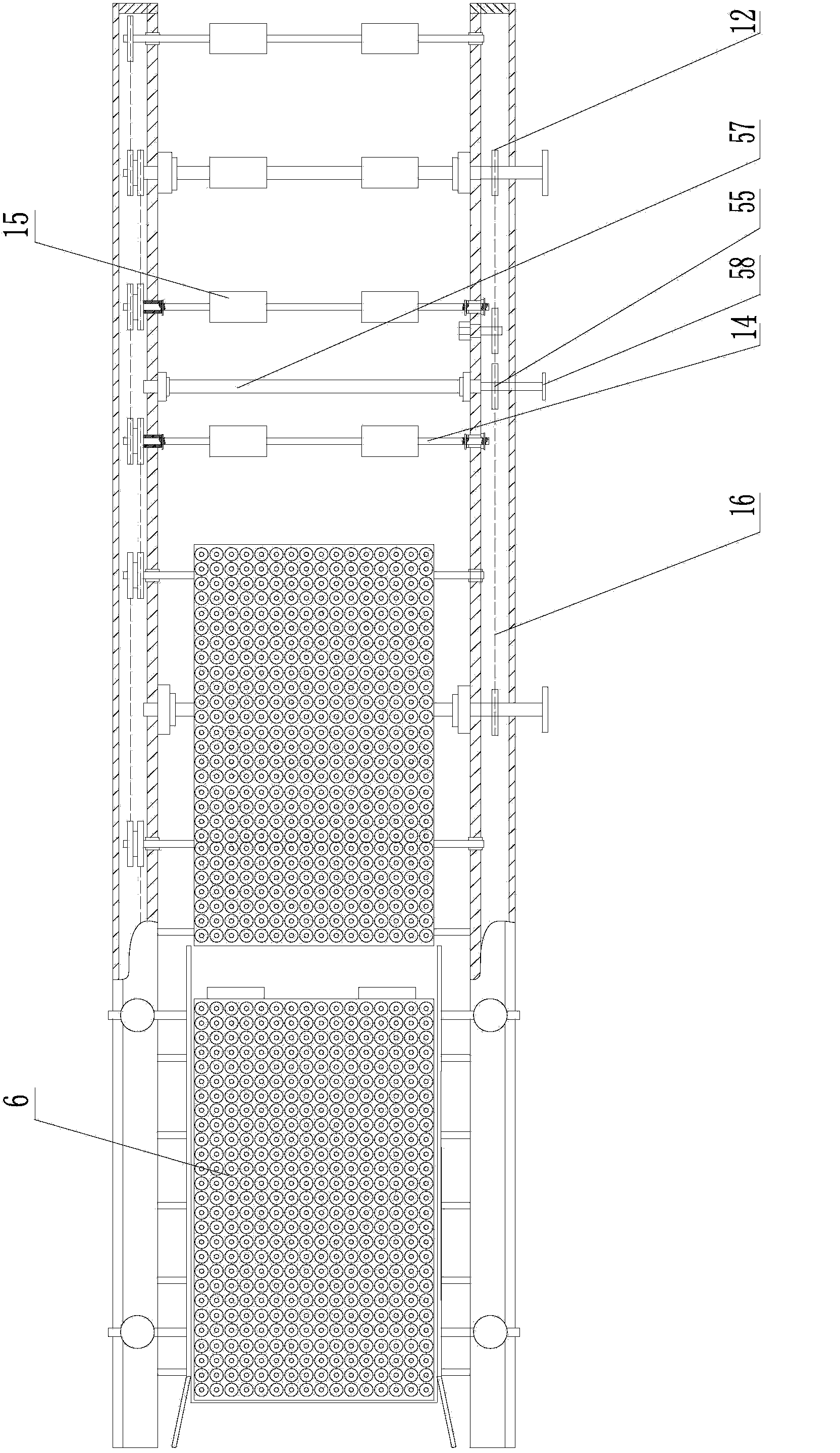

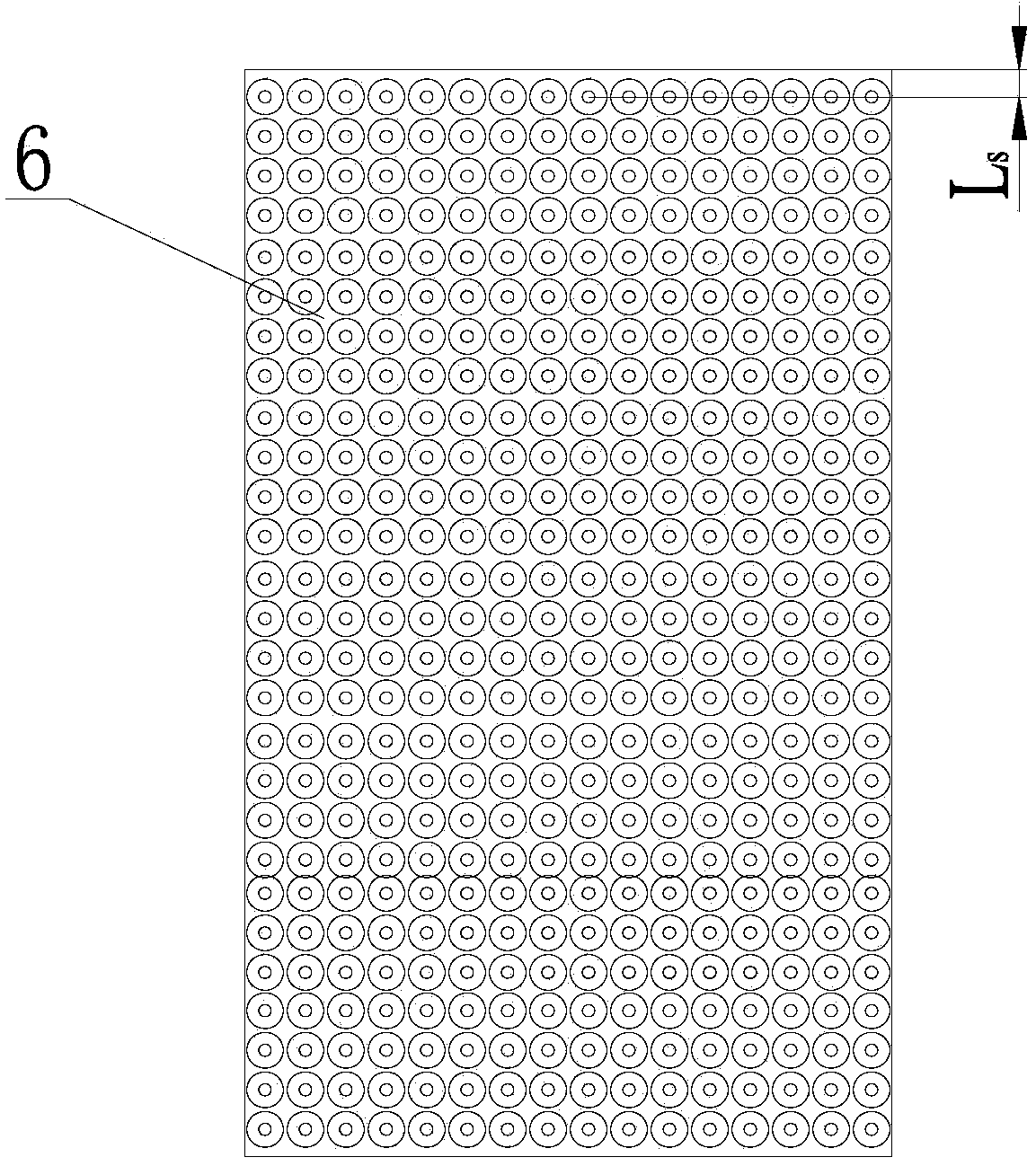

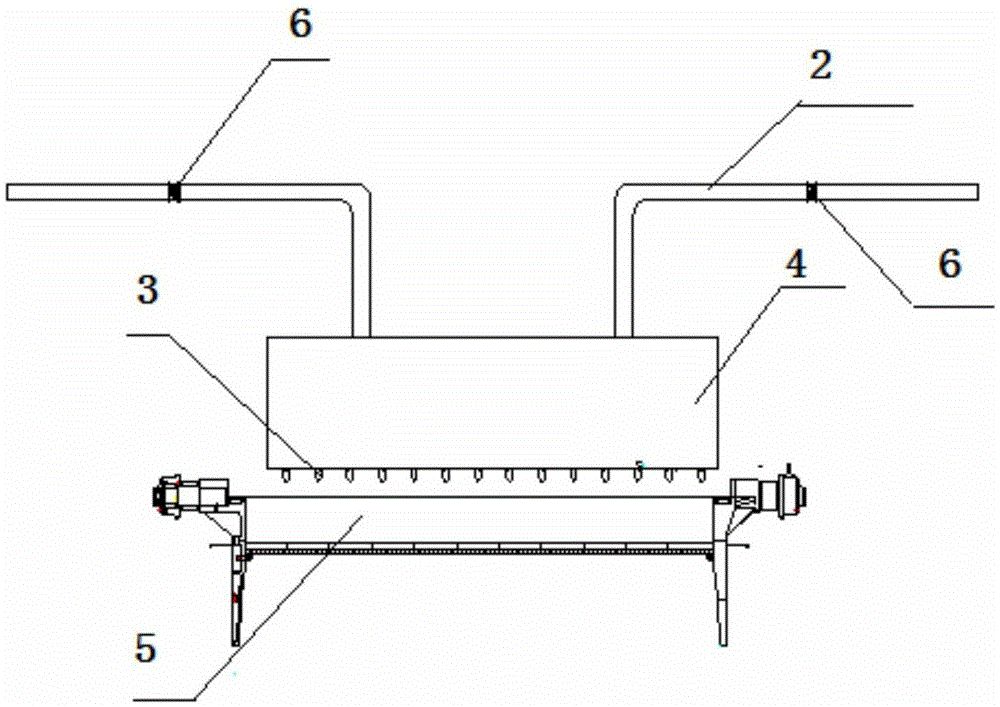

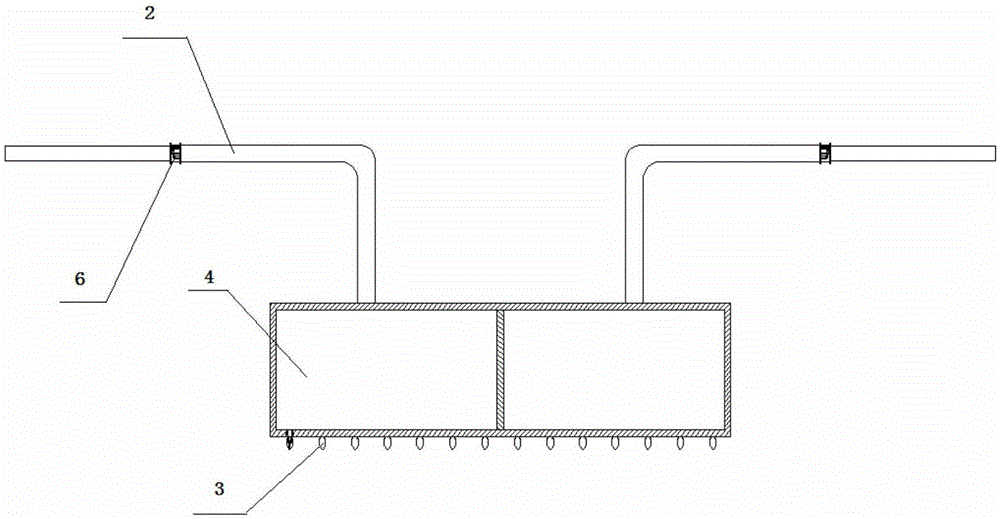

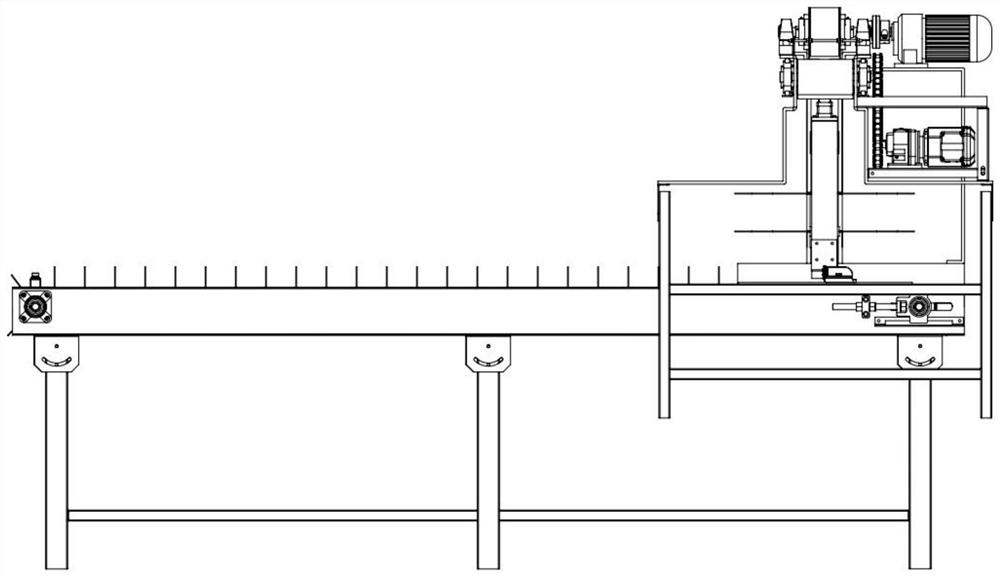

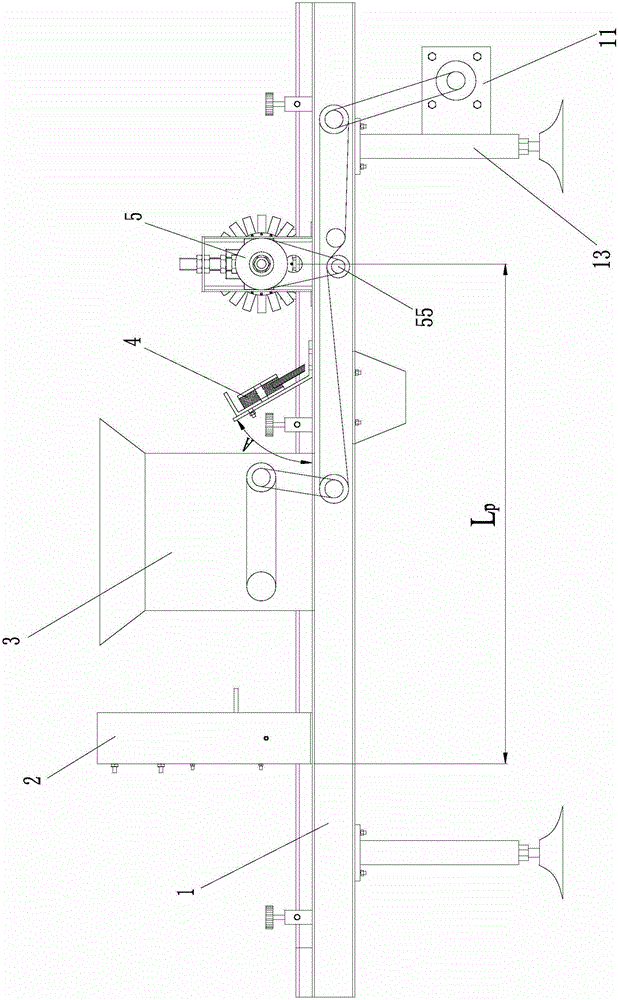

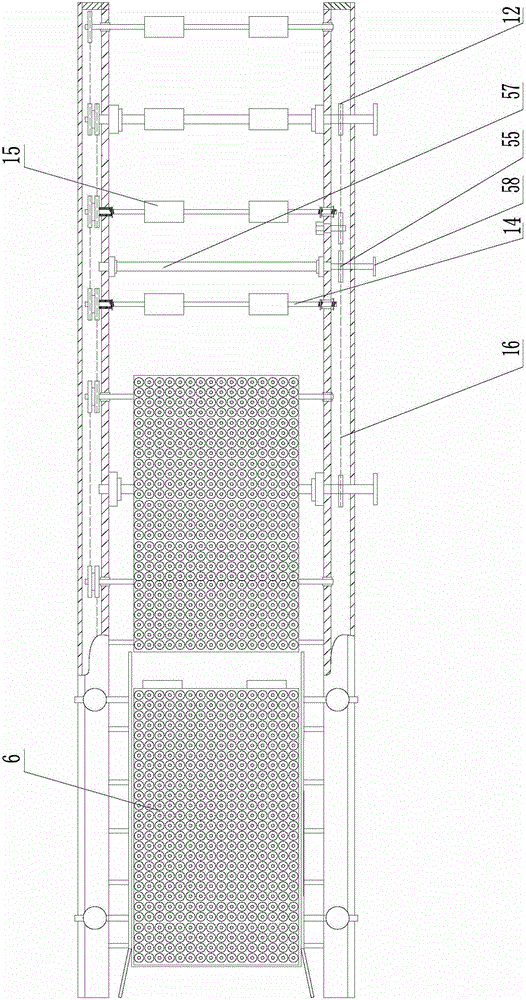

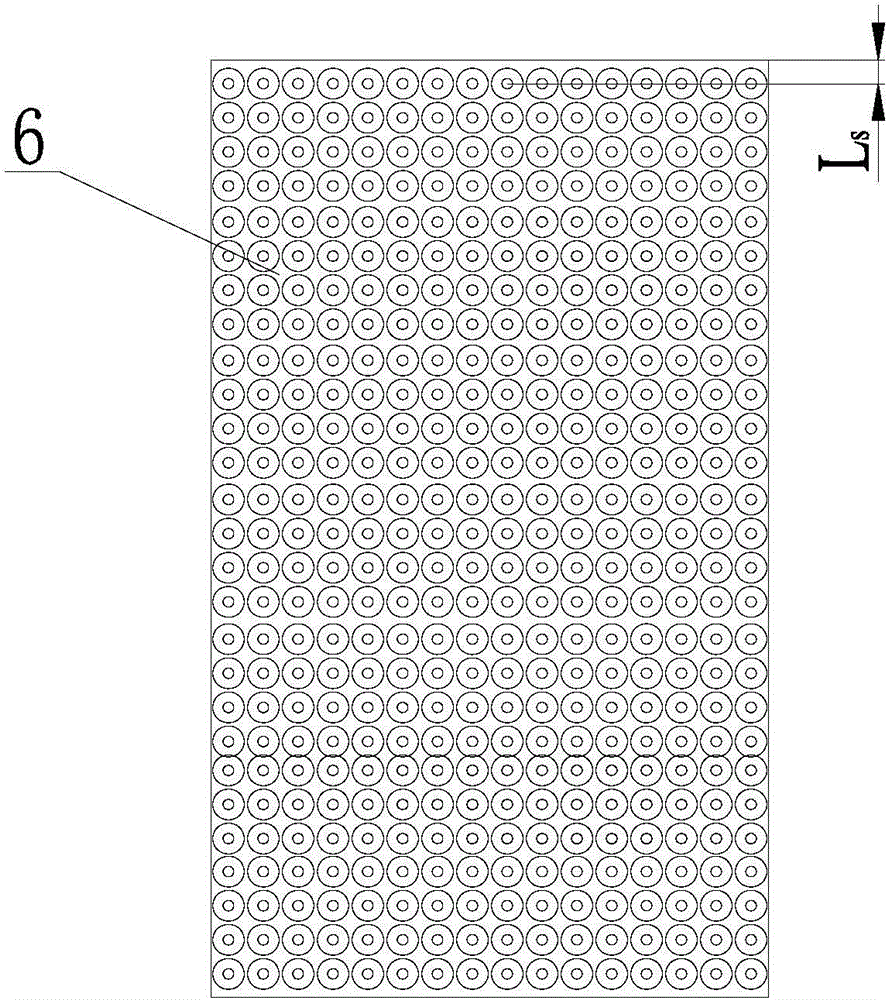

Recycle production line and recycle technology of PET (Polyethylene Terephthalate) bottles

ActiveCN105291304ADrop in timeImprove cleaning efficiencyPlastic recyclingCleaning using liquidsProduction linePolyethylene terephthalate

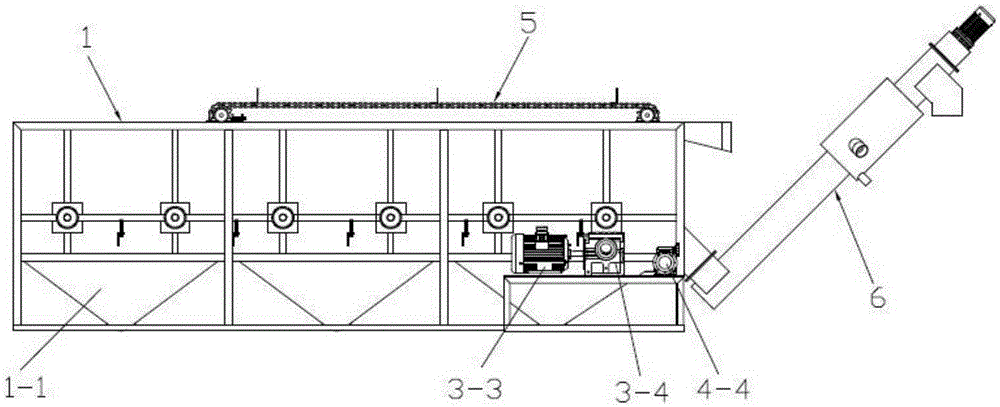

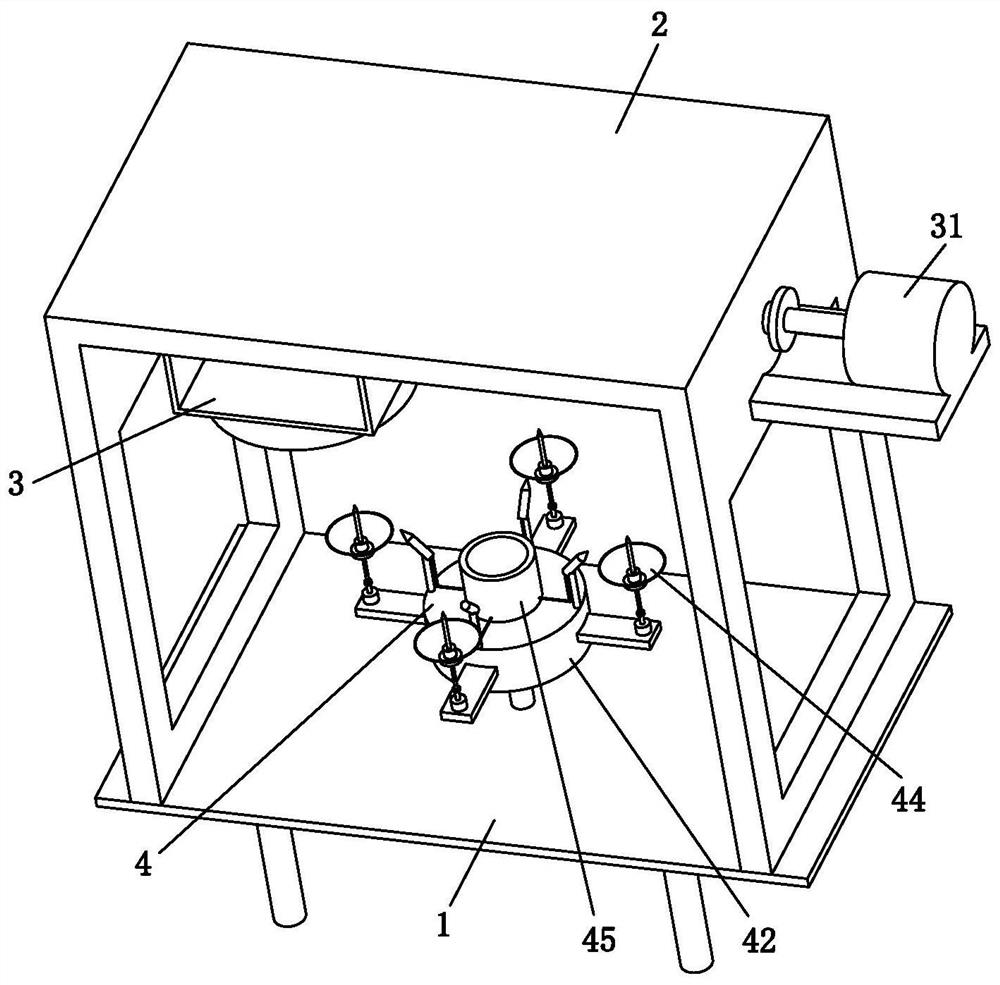

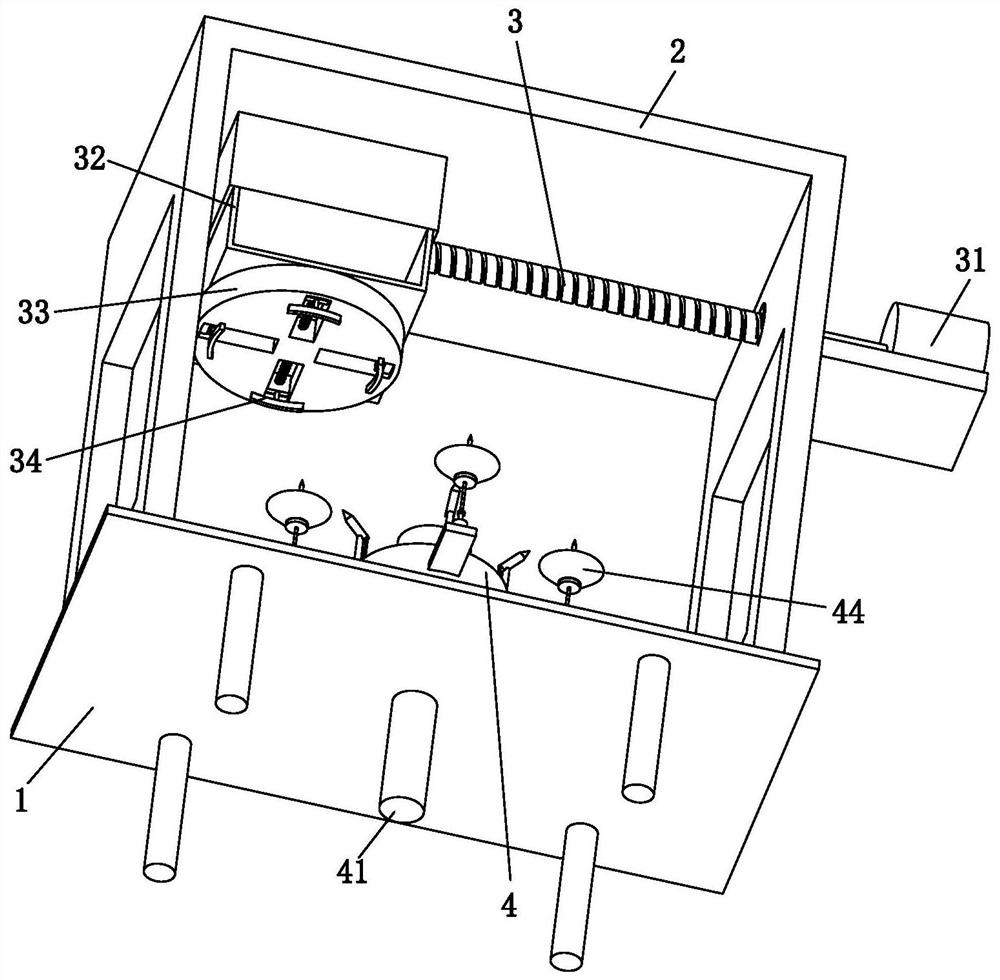

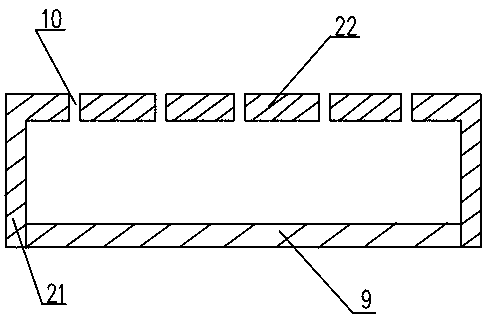

The invention discloses a recycle production line and a recycle technology of PET (Polyethylene Terephthalate) bottles. The recycle production line comprises a first feeding device, a label removing device, a second feeding device, a manual sorting platform, a crusher, a first washing cage, a cleaning and separating device, a high-strength friction cleaning device, a hot-water cleaning device, a first dehydrator, a second washing cage, a second dehydrator, a rinsing device, a third dehydrator and a packer; the cleaning and separating device, the hot-water cleaning device and the rinsing device separately comprise a water tank, stirring cleaners and a mesh screen; each mesh screen tank is formed by sequentially connecting a plurality of arc-shaped mesh screen tank units with upward openings in series along the horizontal direction; a stirring cleaner is arranged above each arc-shaped mesh screen tank unit; each stirring cleaner comprises a rotary shaft and a stirring plate arranged on the rotary shaft; and the rotary shaft of each stirring cleaner is connected with a stirring cleaning driving mechanism. By adopting the production line, the cleaning of fragments is good in effect, high in speed and high in production efficiency.

Owner:冯愚斌

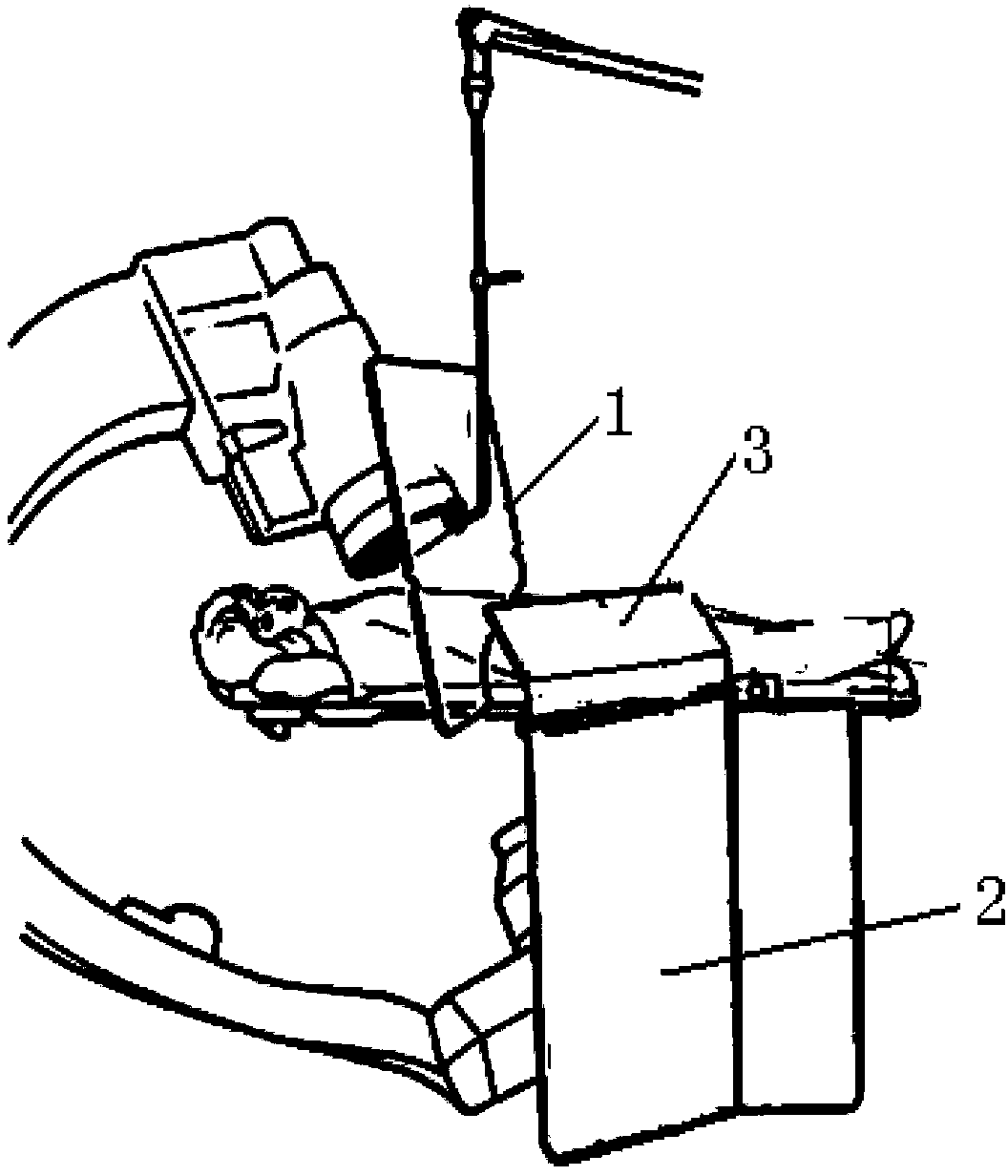

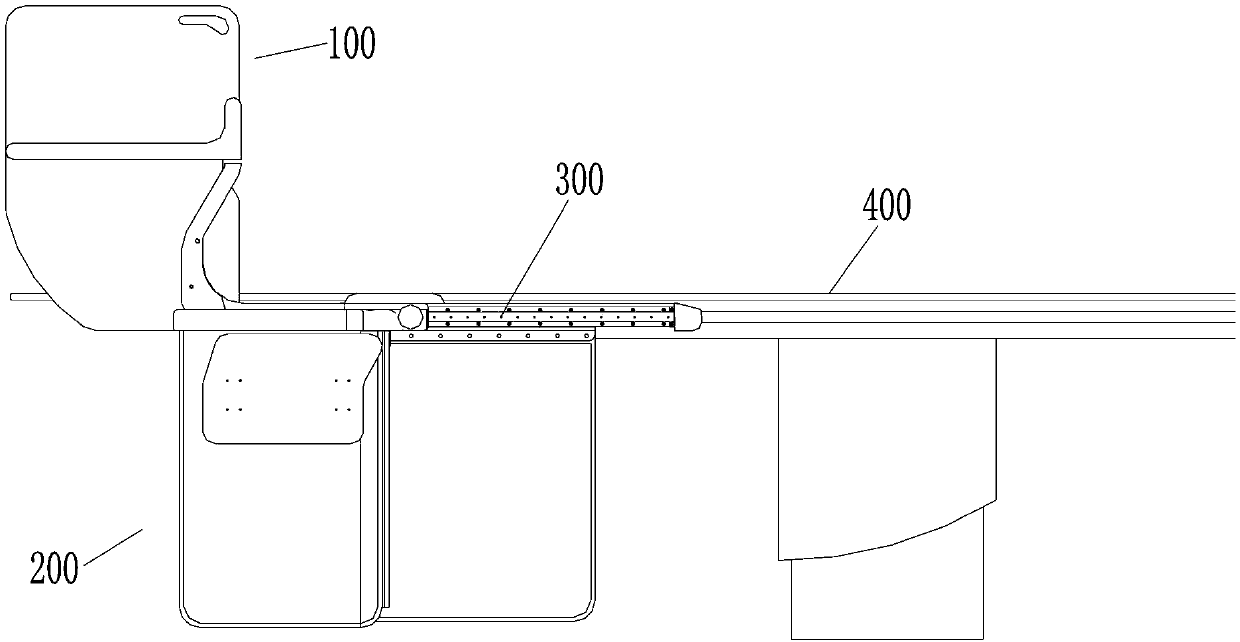

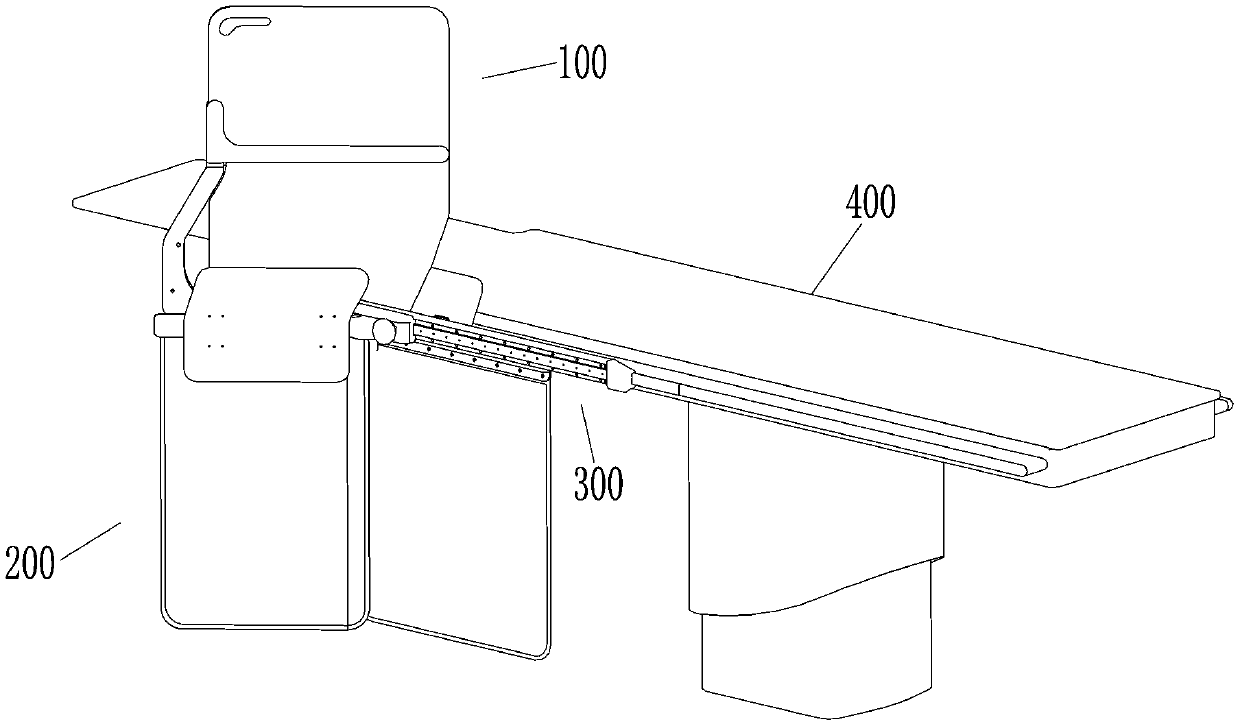

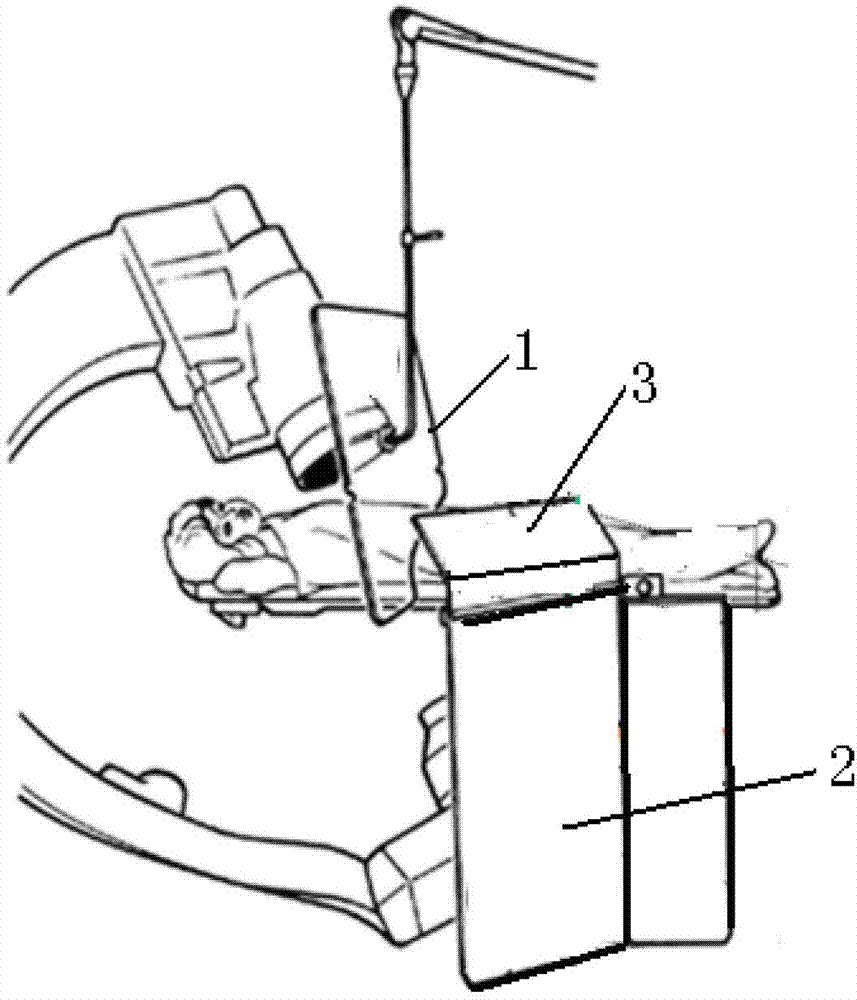

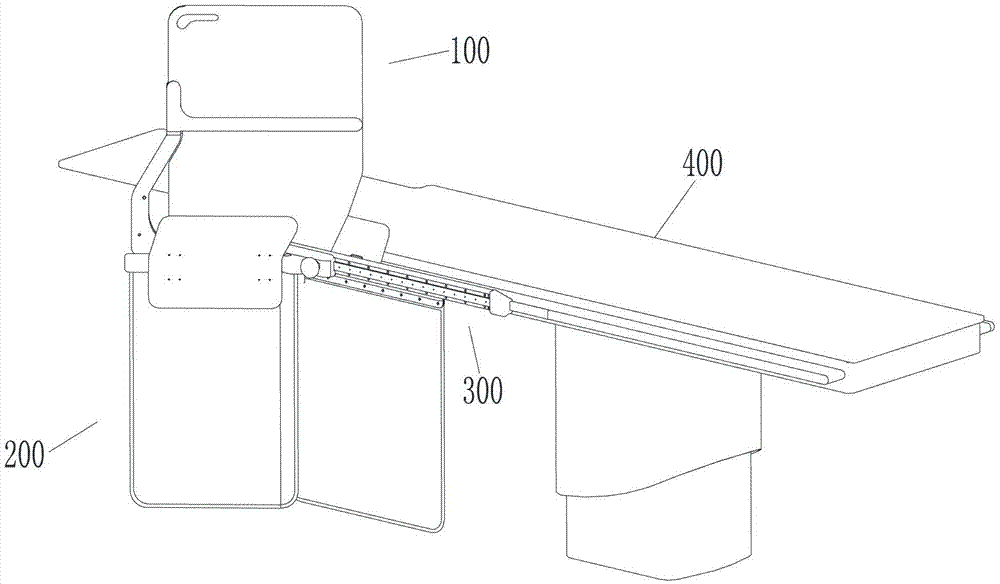

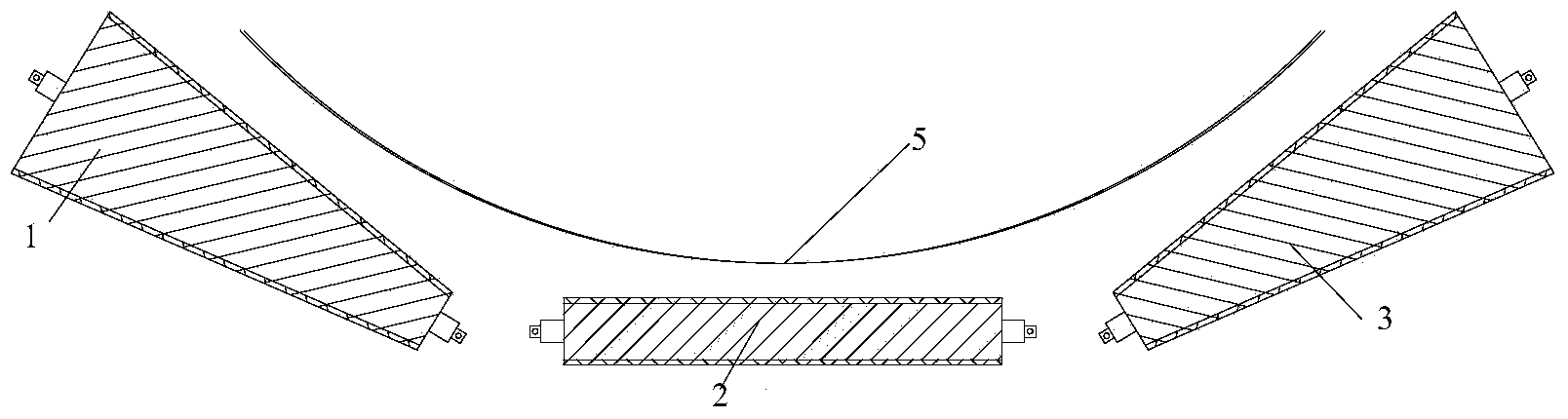

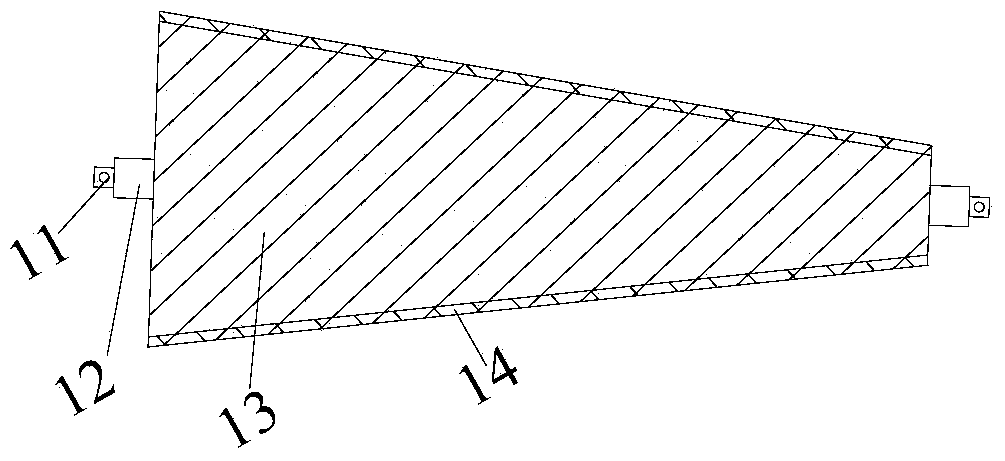

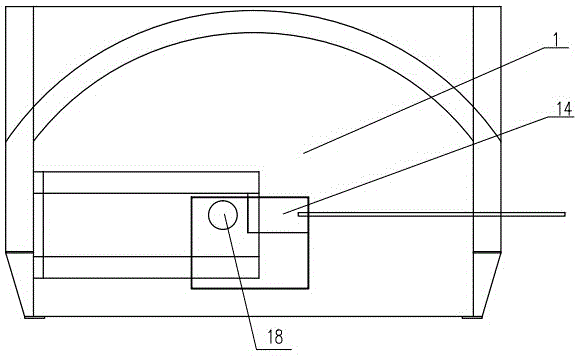

Integrated X-ray protection device on angiography machine

ActiveCN103385733ARealize simultaneous movement with the bedRealize synchronized movementRadiation safety meansAngiographyX-rayEngineering

The invention relates to the field of medical instruments, in particular to an X-ray protection device with an integrated structure for an angiography machine. The device comprises a protection screen unit, a protection curtain unit and a bedside sliding rail unit, wherein the protection screen unit is arranged on the protection curtain unit, and the protection curtain unit is fixed on the bedside sliding rail unit so as to enable the protection curtain unit and the protection screen unit to synchronously and horizontally move along a bedside. The protection device can synchronously move along with a bed, and in a moving process, the protection device is always in the best protecting state and close to a patient, so that the problem that the radiation, especially the secondary stray radiation caused by the rays reflected by the patient, can not be effectively shielded due to the movement of the bed surface of a conduit bed is effectively solved, and meanwhile, the problems of prolonged surgery time, increased surgery risk and the like that are caused by adjusting the protection screen unit during surgery in the prior art are effectively avoided.

Owner:BEIJING ORIENTAL E T MEDICAL EQUIP

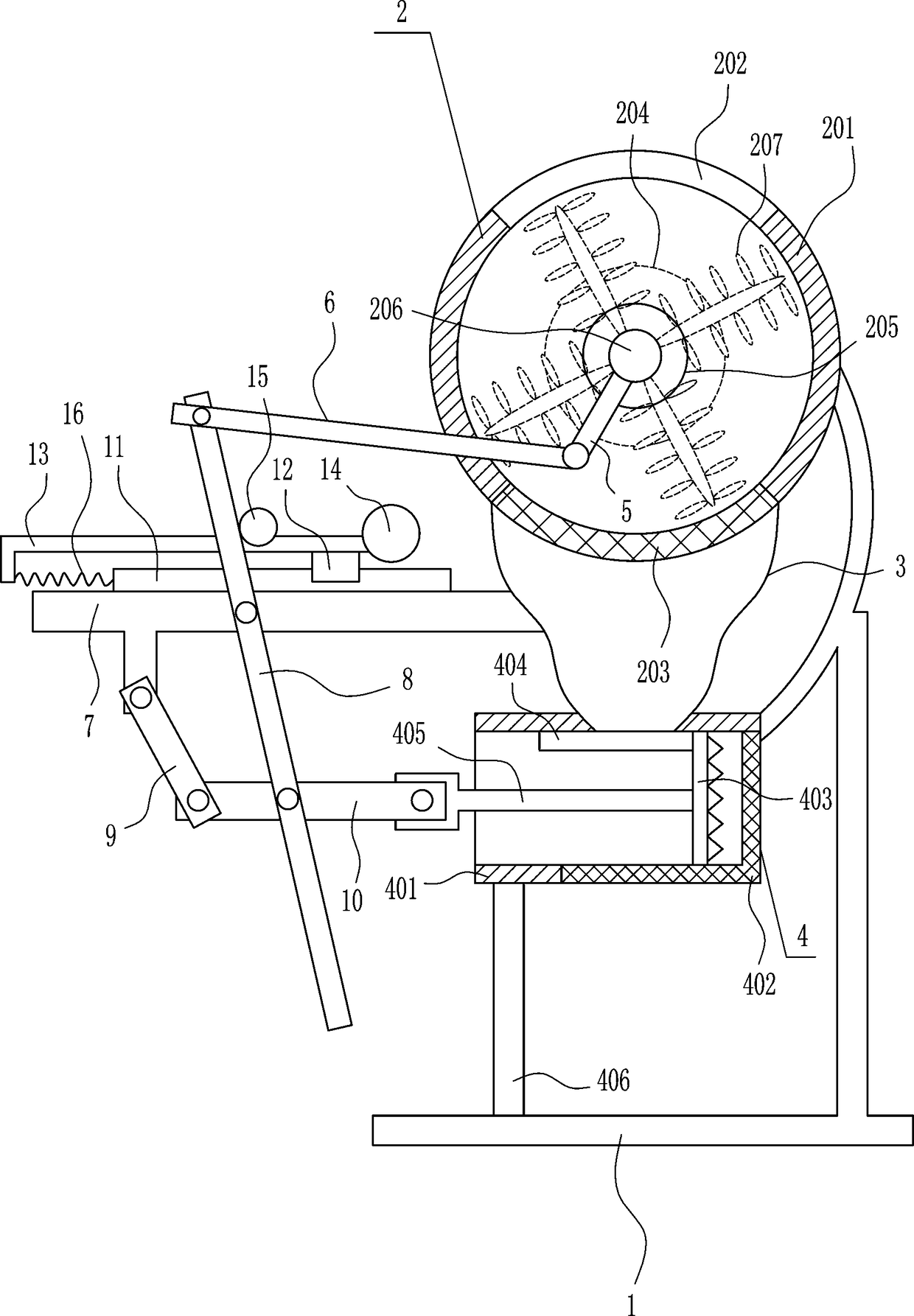

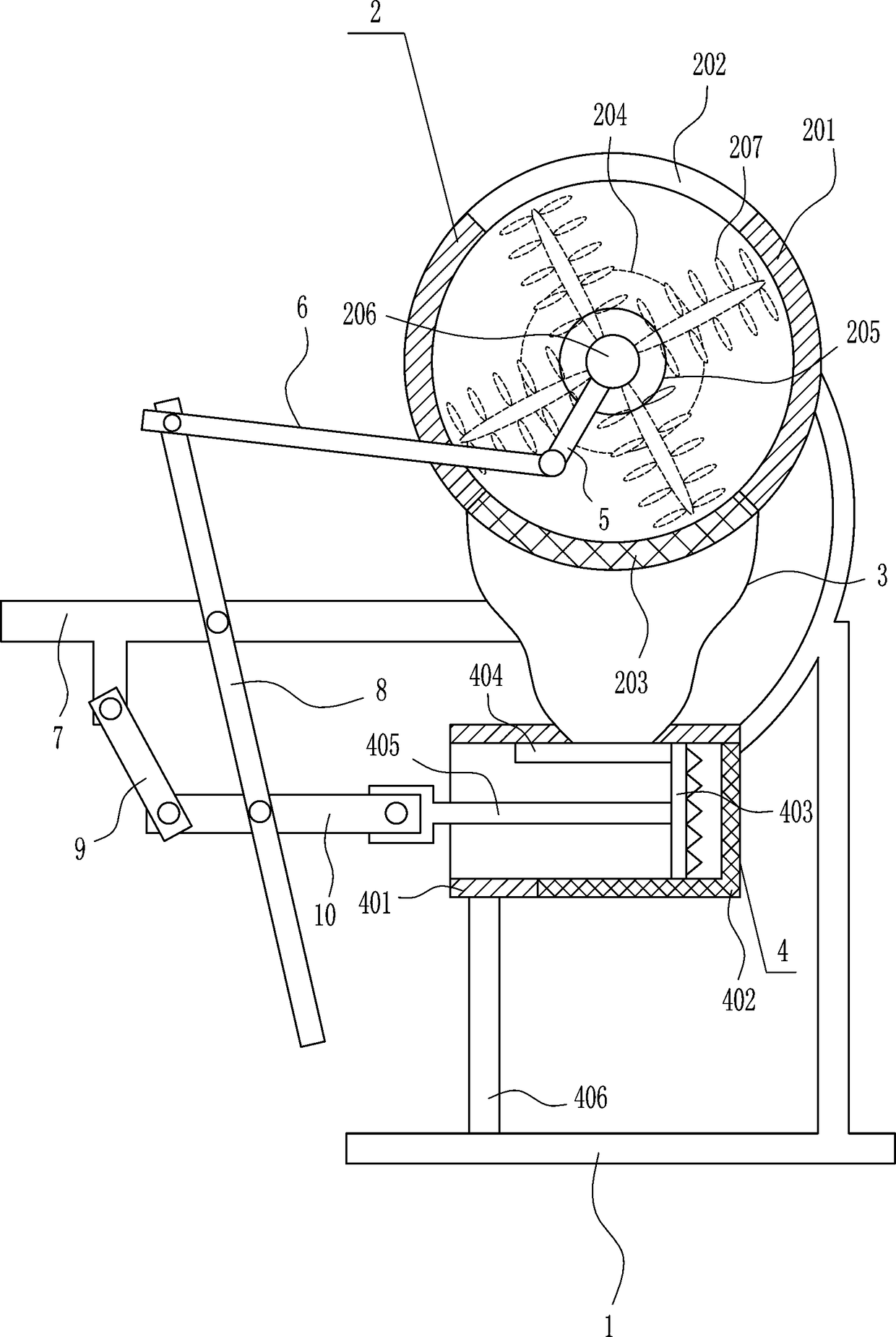

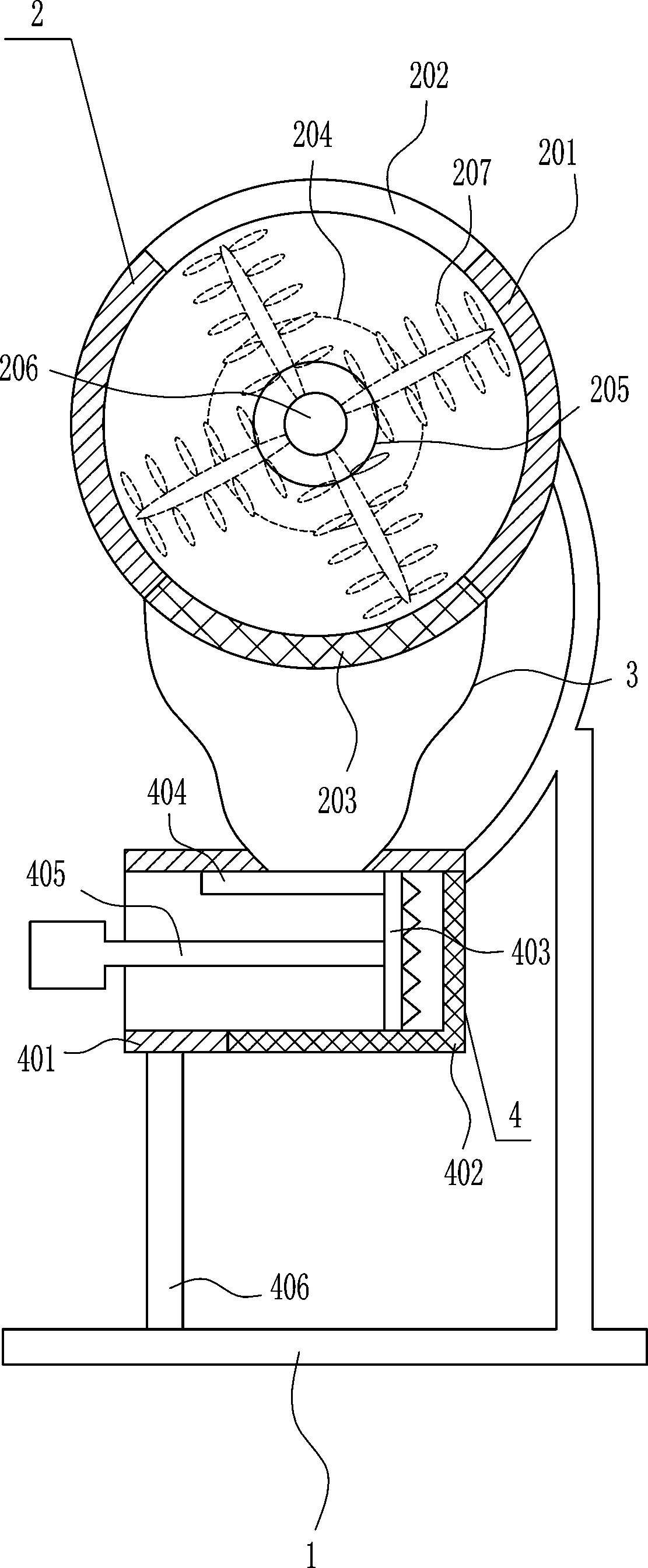

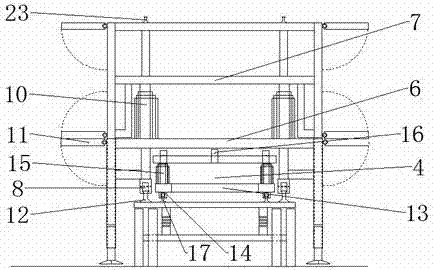

Agglomerated fertilizer de-agglomerating facility for garden fertilizing

InactiveCN108057501AEvenly brokenImprove crushing efficiencySievingScreeningAgricultural engineeringUniform size

The invention relates to a de-agglomerating facility, in particular, an agglomerated fertilizer de-agglomerating facility for garden fertilizing. The invention aims to provide an agglomerated fertilizer de-agglomerating facility for garden fertilizing. The facility does not need artificial grinding, can carry out multistage grinding, and obtains fertilizers with a uniform size after grinding. Theinvention provides an agglomerated fertilizer de-agglomerating facility for garden fertilizing. The facility comprises a frame. The top of the right side of the frame is connected to a primary grinding mechanism, the bottom of the primary grinding mechanism is connected to a discharge bucket, the left side of the bottom of the frame is connected to a secondary grinding mechanism, the top of the second grinding mechanism is connected to the bottom of the discharge bucket, the secondary grinding mechanism is arranged right under the primary grinding mechanism, and the right side of the secondarygrinding mechanism is connected to the upper side of the frame. The facility can grind agglomerated fertilizers without using hands, can carry out multistage grinding of agglomerated fertilizers, andobtains fertilizers with a more uniform size.

Owner:郭巧明

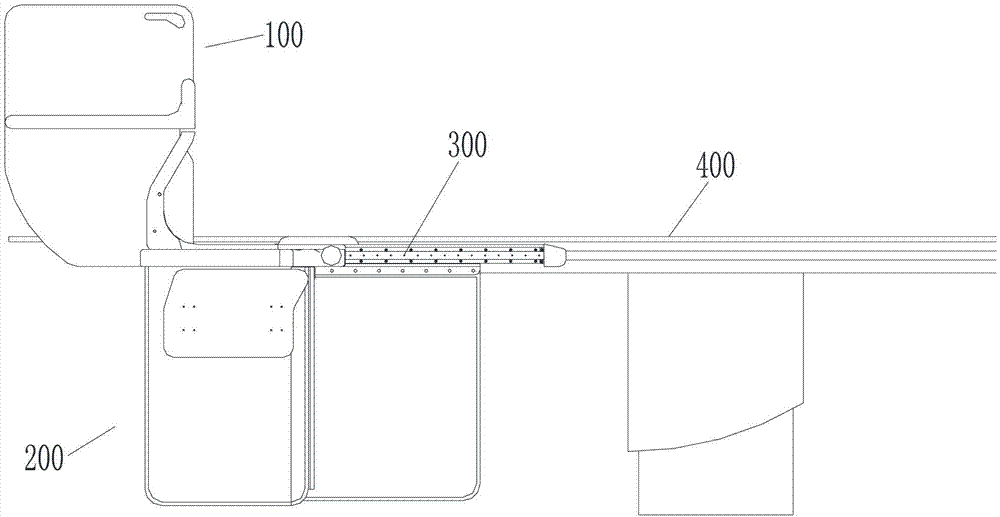

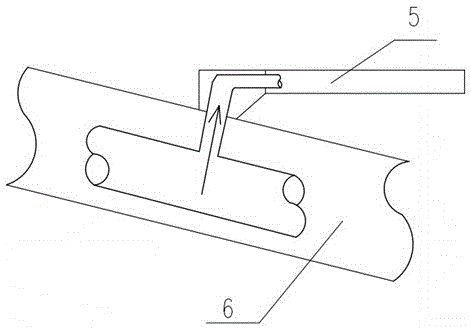

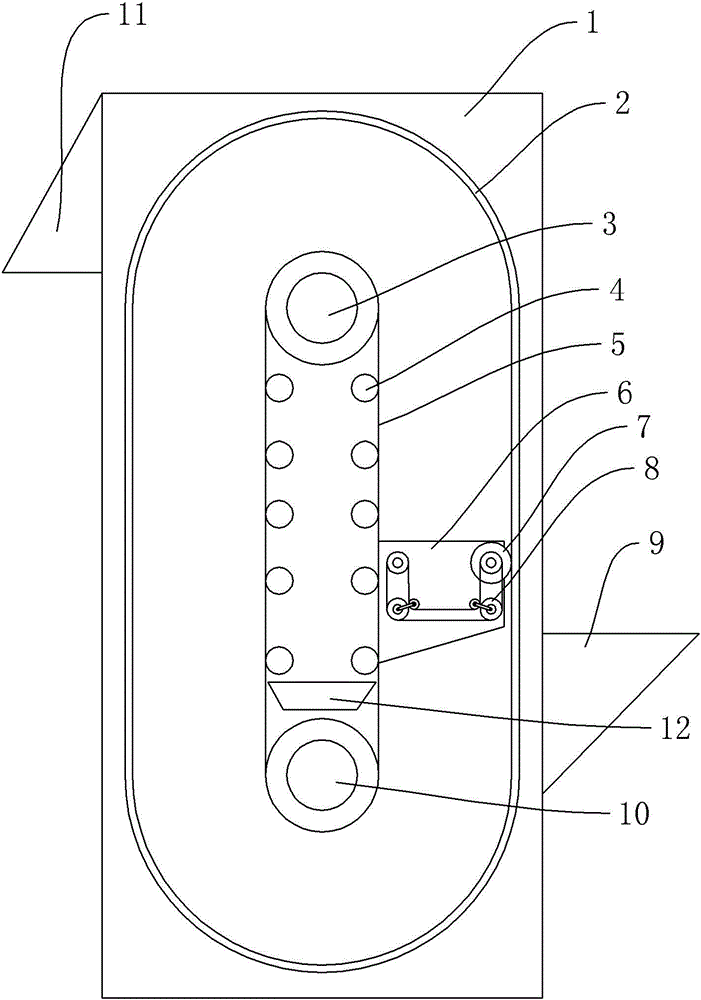

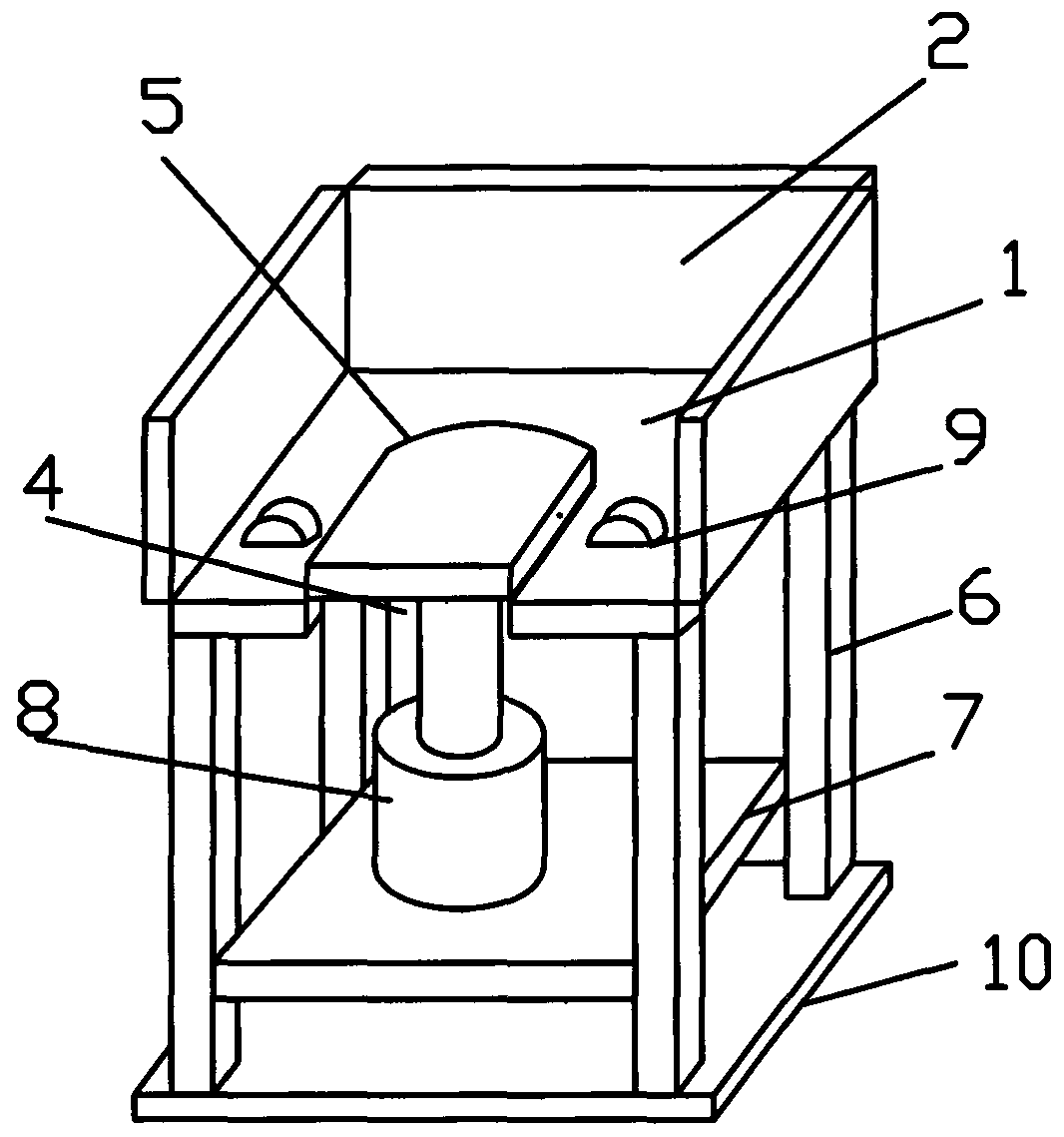

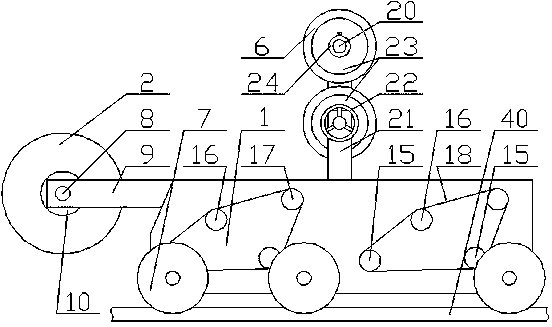

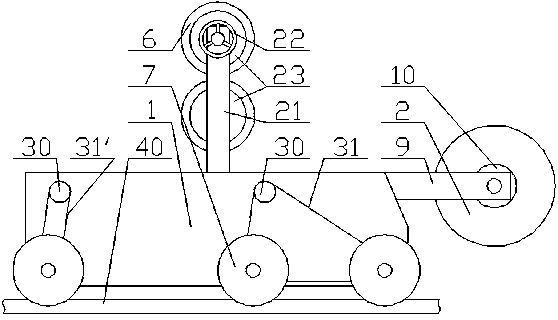

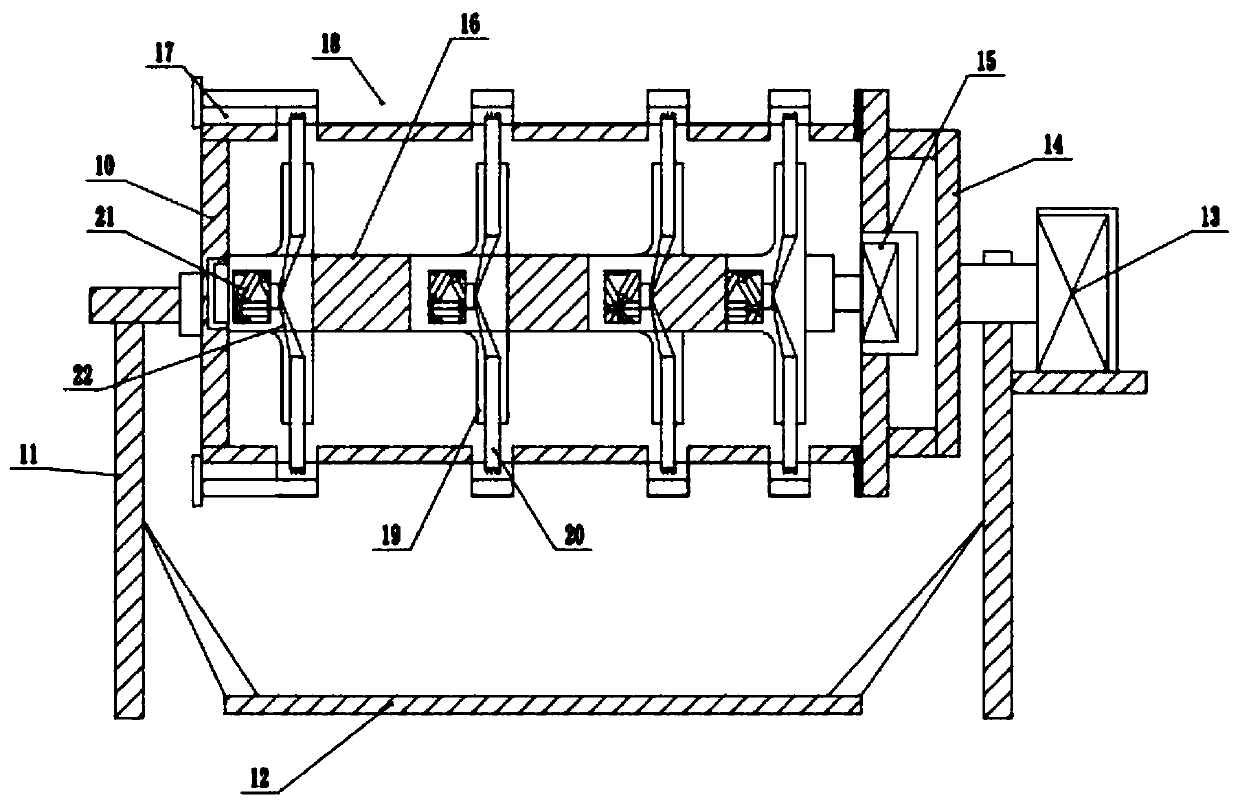

Bottom soil compacting device of rice seedling precisely-raising planter

ActiveCN103548432AWork reliablyImprove efficiencyAgricultural rollersAgricultural engineeringDrive motor

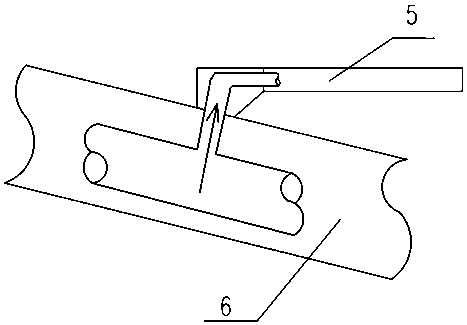

The invention discloses a bottom soil compacting device of a rice seedling precisely-raising planter. The bottom soil compacting device comprises a frame, a hole aligning mechanism and a bottom soil compacting mechanism, wherein the hole aligning mechanism and the bottom soil compacting mechanism are arranged on the frame, and the frame is provided with a driving motor and a seedling tray conveying mechanism. The hole aligning mechanism comprises a limit baffle, a stepping motor, a limiting travel switch and a tray feeding travel switch; the bottom soil compacting mechanism comprises a compacting roller shaft with radially-extending roller fingers and a roller finger position detecting mechanism. According to the bottom soil compacting device of the rice seedling precisely-raising planter, the travel of seedling trays and the roller fingers are limited, the limit travel switch, the tray feeding travel switch and a roller finger position detector control seedling tray feeding and the positions of the finger rollers respectively, meanwhile, the linear speed and the rotation direction of the compacting roller shaft are identical to the seedling tray conveying speed and the seedling tray conveying direction of the seedling tray conveying mechanism, so that when the seedling trays move to the positions of the roller fingers, the roller fingers can be accurately inserted into the holes of the seedling trays to compact soil. The bottom soil compacting device of the rice seedling precisely-raising planter is reliable in operation, high in efficiency and wide in market application and popularization prospect.

Owner:SOUTH CHINA AGRI UNIV

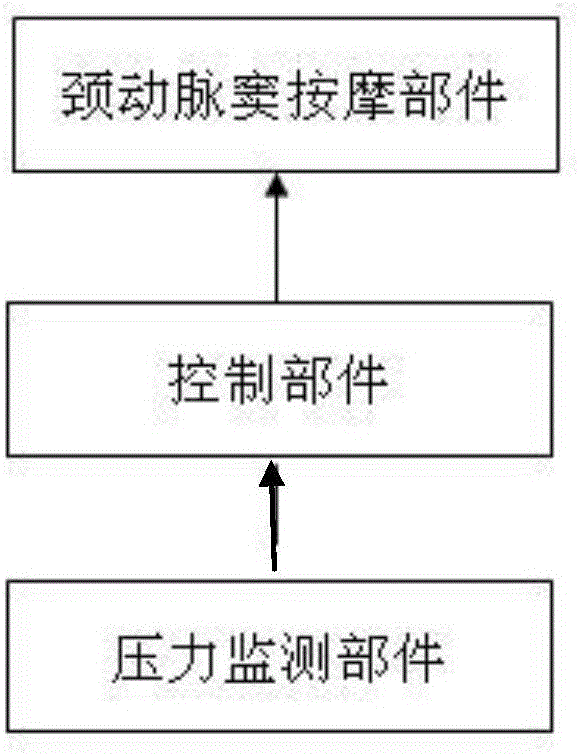

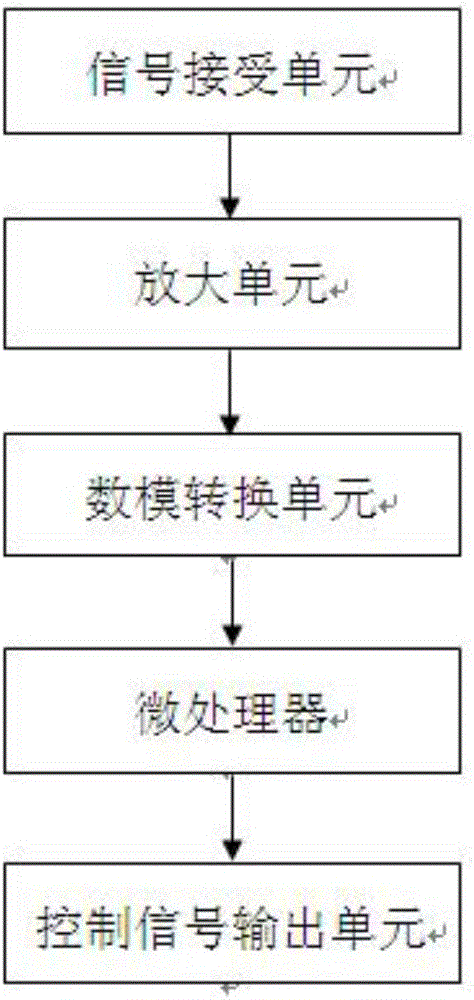

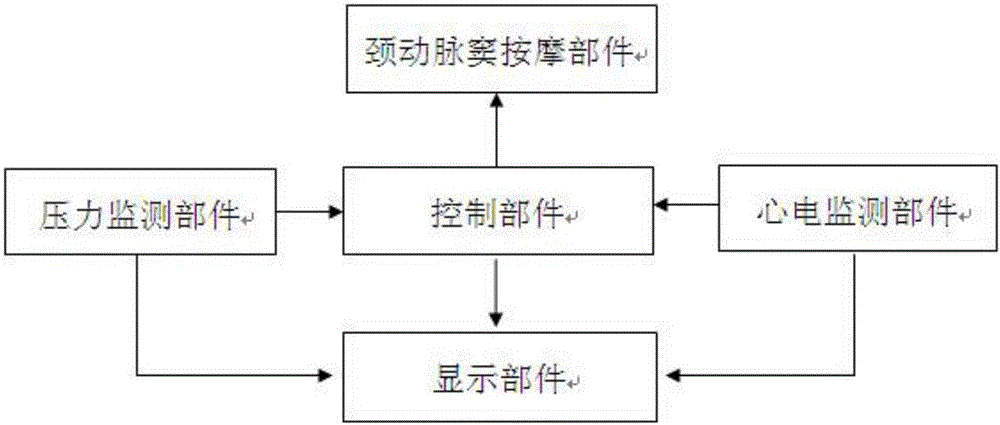

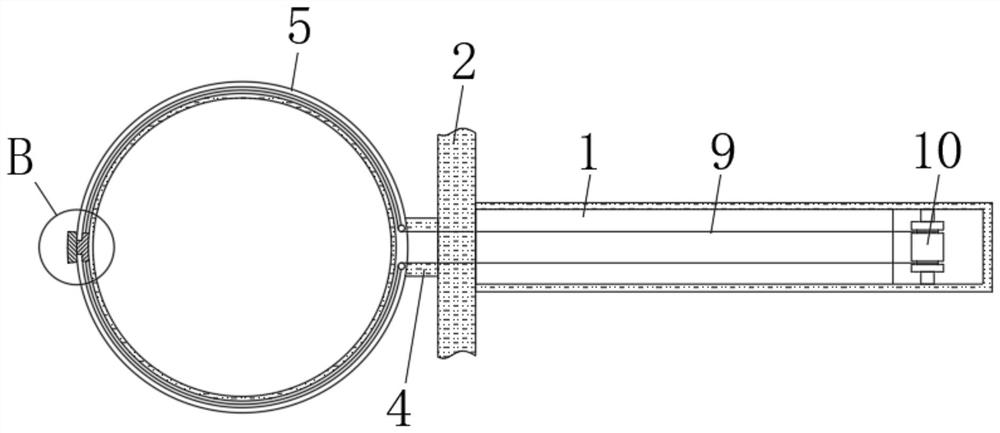

Skin-outer carotid sinus massage blood-pressure-reducing device

InactiveCN105943348ADrop in timeRealize individualized and intelligent blood pressure reductionVibration massageEvaluation of blood vesselsMassageCarotid sinus

The invention belongs to the field of medical apparatus and instruments, and in particular relates to a skin-outer carotid sinus massage blood-pressure-reducing device. The skin-outer carotid sinus massage blood-pressure-reducing device comprises a carotid sinus massage part, a pressure monitoring part, a control part, a display part, an electrocardiogram monitoring part and a fixing part, wherein a microprocessor of the control part analyzes a pressure signal from the pressure monitoring part, so that the massage mode of the carotid sinus massage part fixed to the local skin-outer part of the carotid sinus is adjusted, and thus the feedback blood pressure reduction is realized. The skin-outer carotid sinus massage blood-pressure-reducing device is used for treating high blood pressure, is a noninvasive blood pressure reducing device, is convenient to use, is safe and effective, and has a great clinical application value.

Owner:张健

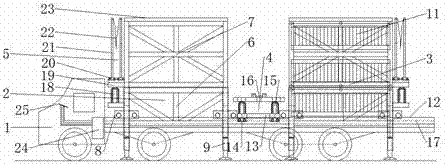

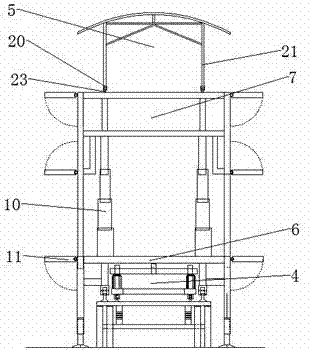

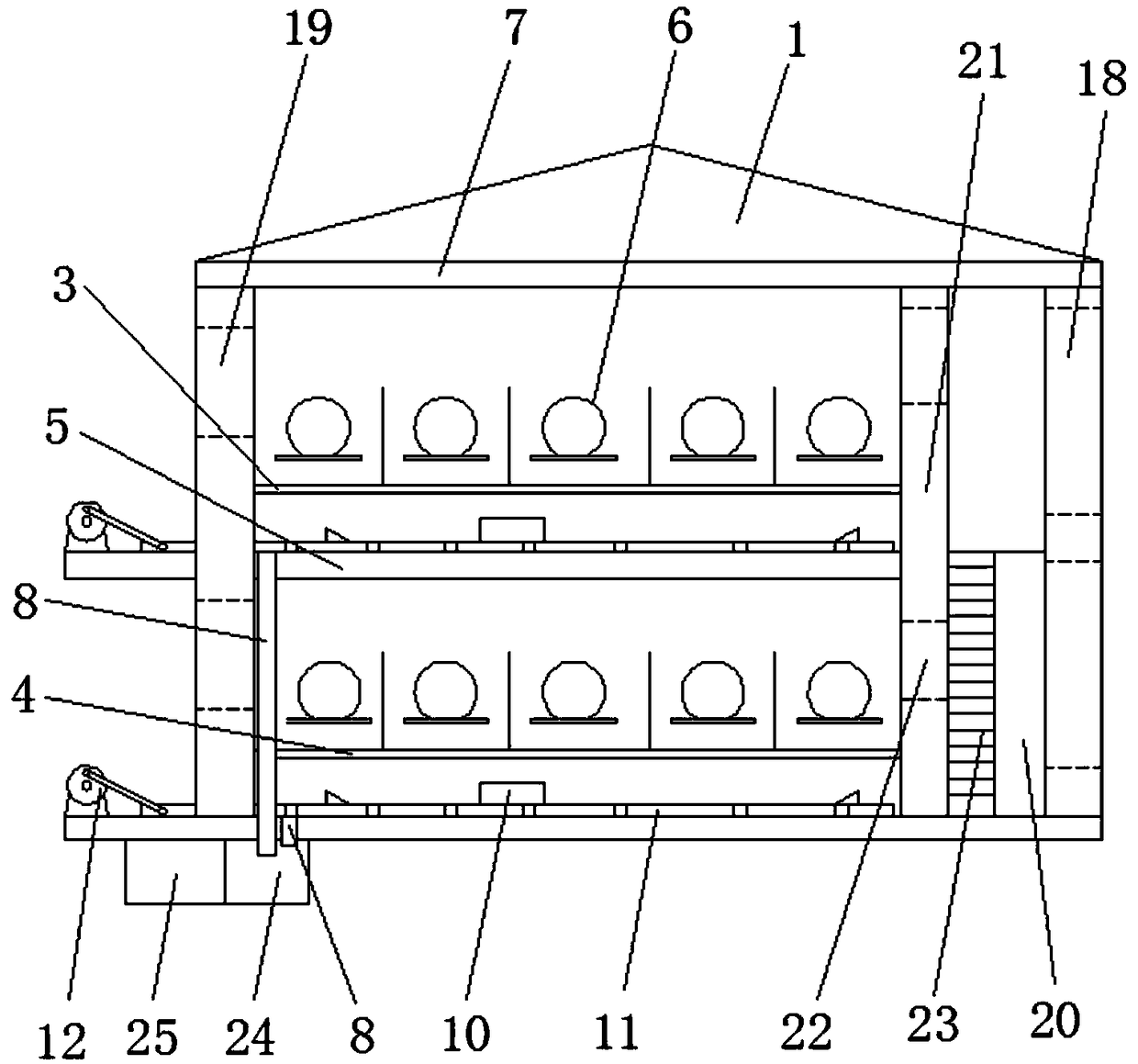

Movable-type hydraulic work protective platform in tunnel

PendingCN107882582AMove quicklyEasy to maintainUnderground transportProps/chocksCivil engineeringArchitectural engineering

The invention relates to the technical field of civil engineering, in particular to a movable-type hydraulic work protective platform applied into a tunnel. The movable-type hydraulic work protectiveplatform comprises a flat transporting trolley, a wheeltrack-type hydraulic lifting rack part mounted on a trolley body, a wheeltrack-type hydraulic lifting arching mounting trolley part and a wheeltrack-type hydraulic lifting telescopic protective rack part. The wheeltrack-type hydraulic lifting rack part comprises a wheeltrack-type hydraulic lifting rack which comprises a rack upper part and a rack lower part. The rack lower part is provided with a rack travelling device and supporting legs for supporting the hydraulic lifting rack, and the rack upper part is provided with a lifting device and a foldable working platform. The wheeltrack-type hydraulic lifting arching mounting trolley part comprises a mounting trolley mounted on the trolley working platform. The wheeltrack-type hydrauliclifting telescopic protective rack part comprises a wheeltrack-type hydraulic lifting telescopic protective rack, a protective rack lifting device and a protective rack lifting platform. The movable-type hydraulic work protective platform has the technical advantage that the safety degree of centralized operation is high.

Owner:THE 2ND ENG CO LTD OF CHINA RAILWAY 17 BUREAU GRP

Integrated X-ray protection device on angiography machine

ActiveCN103385733BRealize simultaneous movement with the bedRealize synchronized movementRadiation safety meansAngiographyX-rayEngineering

The invention relates to the field of medical instruments, in particular to an X-ray protection device with an integrated structure for an angiography machine. The device comprises a protection screen unit, a protection curtain unit and a bedside sliding rail unit, wherein the protection screen unit is arranged on the protection curtain unit, and the protection curtain unit is fixed on the bedside sliding rail unit so as to enable the protection curtain unit and the protection screen unit to synchronously and horizontally move along a bedside. The protection device can synchronously move along with a bed, and in a moving process, the protection device is always in the best protecting state and close to a patient, so that the problem that the radiation, especially the secondary stray radiation caused by the rays reflected by the patient, can not be effectively shielded due to the movement of the bed surface of a conduit bed is effectively solved, and meanwhile, the problems of prolonged surgery time, increased surgery risk and the like that are caused by adjusting the protection screen unit during surgery in the prior art are effectively avoided.

Owner:BEIJING ORIENTAL E T MEDICAL EQUIP

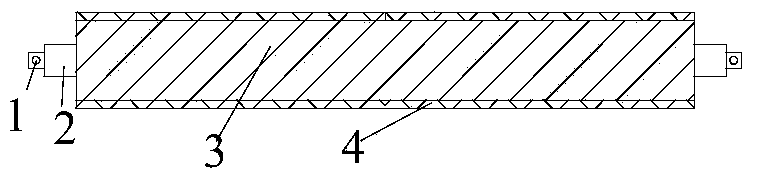

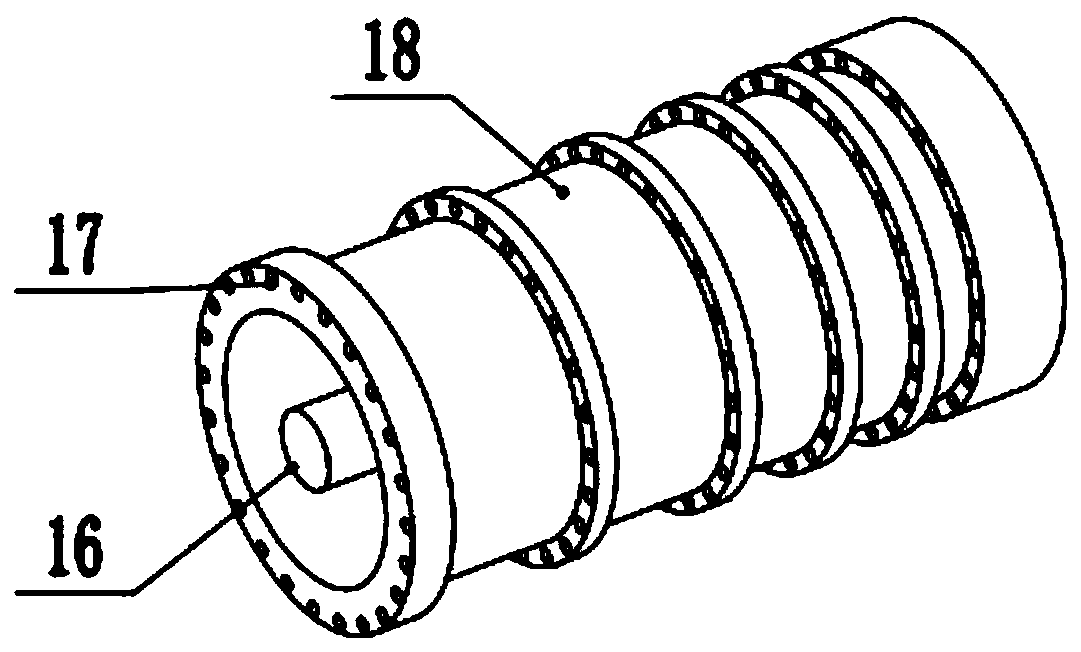

Cylinder device of belt conveyer

The invention discloses a cylinder device of a belt conveyer. Compared with the prior art, the cylinder device is mainly characterized in that a middle cylinder body is cylindrical, a left cylinder body and a right cylinder body are of a circular truncated cone shape, a right shaft of the left cylinder body and a first joint bearing arranged on a left machine frame of the belt conveyer are rotatably connected, a left shaft of the right cylinder body and a second joint bearing arranged on a right machine frame of the belt conveyer are rotatably connected, the outer surface of the left cylinder body, the outer surface of the middle cylinder body and the outer surface of the right cylinder body are all rubber lining layers, and a plurality of grooves are formed in the surfaces of the rubber lining layers. The cylinder device can guarantee that a belt runs more stably and does not deviate in the work process of the belt conveyer, and adjustment is easy and convenient to achieve when the belt deviates.

Owner:SHANDONG UNIV OF SCI & TECH

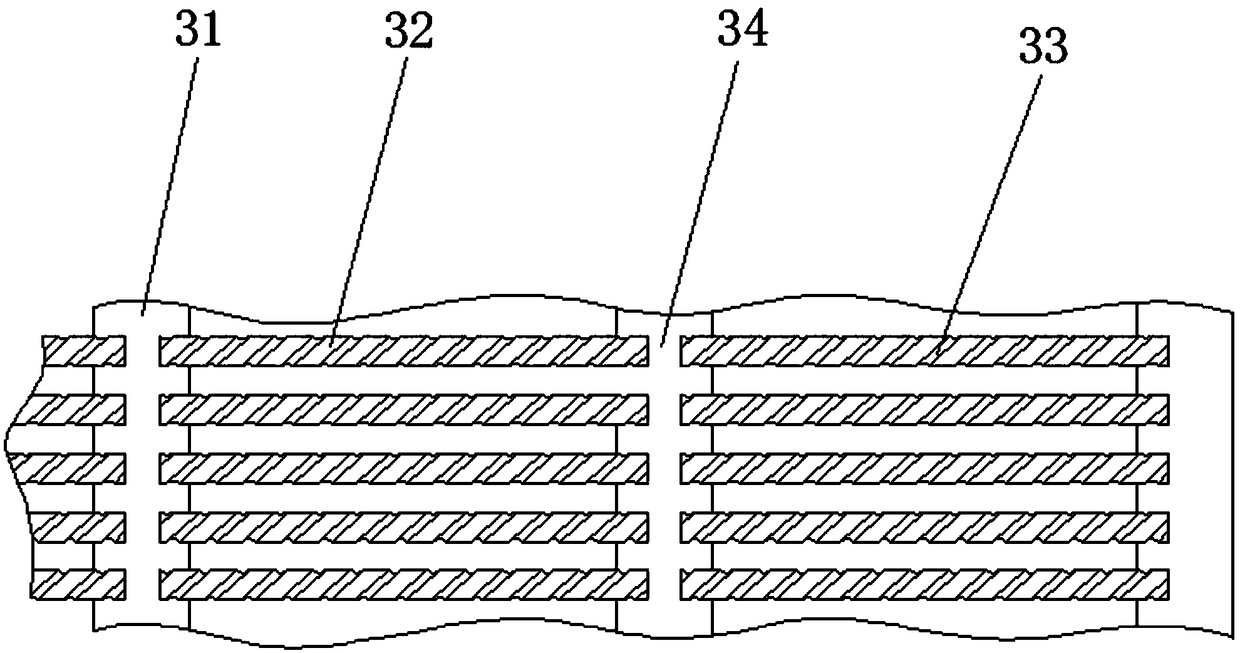

Automatic decoking combustion chamber for combusting biomass fuel

The invention discloses an automatic decoking combustion chamber for combusting biomass fuel, and belongs to the technical field of combustion equipment. The automatic decoking combustion chamber for combusting the biomass fuel comprises movable grate plates arranged in a furnace and fixed grate plates fixed in the furnace, the movable grate plates move front and back and are in friction fit with the fixed grate plates, the fixed grate plates and the movable grate plates are alternately arranged in a stair-step mode and sequentially descend from a furnace mouth of the furnace to the back portion of the furnace, and all the movable grate plates act synchronously; each furnace grate plate comprises a groove-shaped metal cover plate, plate legs of the metal cover plate are in friction fit with the plate surface of the furnace grate plate below the metal cover plate, the plate surface of the furnace grate plate is provided with multiple air holes, and the lower surface of the furnace grate plate is provided with an air supply system which supplies air to the furnace through the air holes; the automatic decoking combustion chamber for combusting the biomass fuel is further provided with a hopper, a material pushing plate and an igniter. According to the automatic decoking combustion chamber for combusting the biomass fuel, the market vacancy is filled, the problem that sticky jelly-like matter generated in the combustion process of the biomass fuel blocks the air holes of the furnace grate plates is effectively solved, decoking is automatically performed, materials are distributed evenly, and full combustion is guaranteed; the automatic decoking combustion chamber is simple in structure and convenient and fast to operate.

Owner:张露纯

High-value treatment method for recycling pig dung and urine

InactiveCN109020643ALow costAvoid nutrient lossBio-organic fraction processingExcrement fertilisersBiotechnologyFeces

The invention discloses a high-value treatment method for recycling pig dung and urine, capable of maximally avoiding nutrient loss of fertilizers and saving the strain cost by 90% or above. The treatment method comprises the following steps: 1, allowing pigs to excrete dung and urine on a net bed at the upper layer of a pig house; 2, pushing the fresh dung and urine on a lower net bed of the pighouse into a fecal treatment tank by using a fecal scraper, adding granulated brown sugar and a strain into the fecal treatment tank, performing mixing for 0.5-1.5 h, pumping the obtained mixture intoan ectopic fermentation bed, mixing the mixture with straw powder, fermenting the obtained mixture, performing mixing composting, turning over the obtained heap 1-3 times every 5-8 d, and supplementing the strain 20-30 d later to obtain old manure with the water content of 25-35%; and 3, adding fresh dung and urine into the old manure, adding the straw powder, and carrying out secondary fermentation for 40-60 d to obtain a completely-fermented bioorganic fertilizer.

Owner:玉林市容县奇昌种猪养殖有限公司

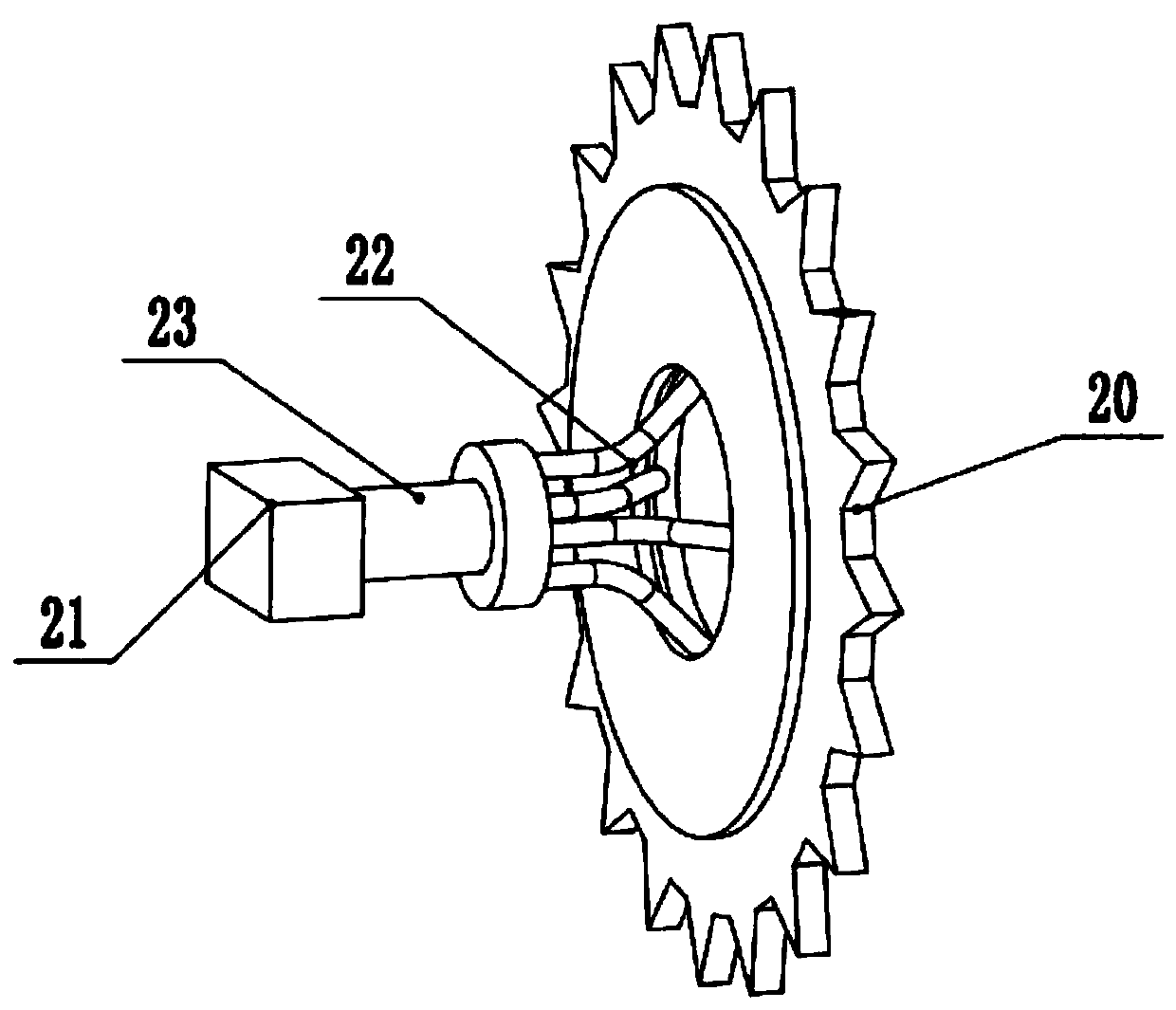

Vertical lifting device of roller mill used for processing steel slag

The invention relates to steel slag processing equipment, in particular to a vertical lifting device of a roller mill used for processing steel slag. The vertical lifting device comprises a housing, wherein a feeding hole is formed in the lower part of the housing; a first discharge hole is formed in the upper part of the housing; a motor is arranged outside the housing; a transmission roller and a turning roller are arranged in the housing; the transmission roller is connected with the motor; a first conveyor belt which is vertically arranged is arranged on the transmission roller and the turning roller; a plurality of conveying hoppers are arranged on the first conveyor belt; second discharge holes are formed in the lower par, close to the side wall of the first conveyor belt, of the conveying hoppers; a group of rotary shafts is arranged in the conveying hoppers; chain wheels are arranged on the rotary shafts; a second conveyor belt is arranged on the chain wheels; the second conveyor belt is positioned on the upper parts of the conveying hoppers; a sieve hole is formed in the second conveyor belt; gears are further arranged on the rotary shafts; a rack matched with the gears is arranged on the housing; and a collecting slot is formed inside the first conveyor belt. The vertical lifting device has the beneficial effect of improving the steel slag grinding efficiency of the roller mill.

Owner:重庆市富环建筑材料有限责任公司

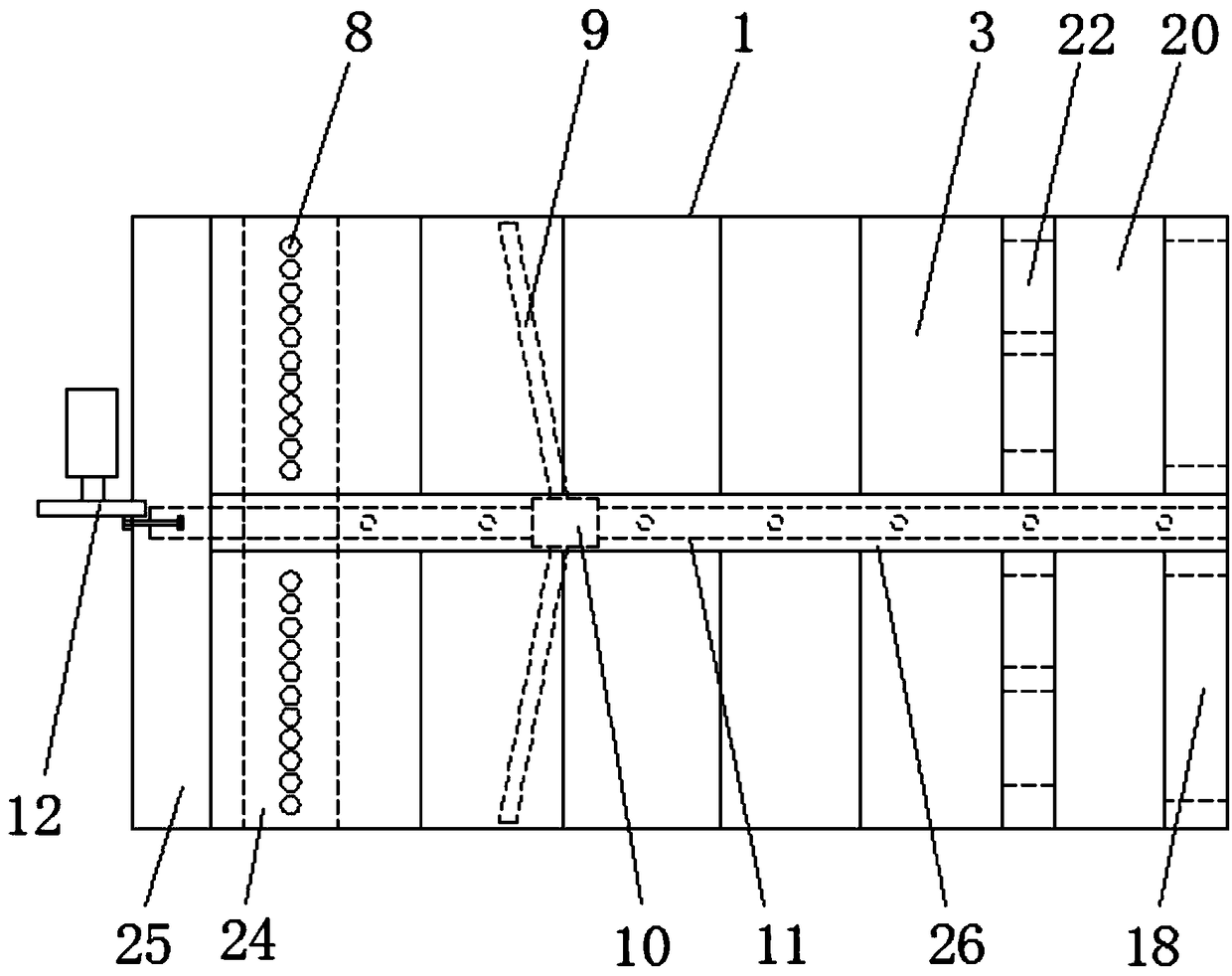

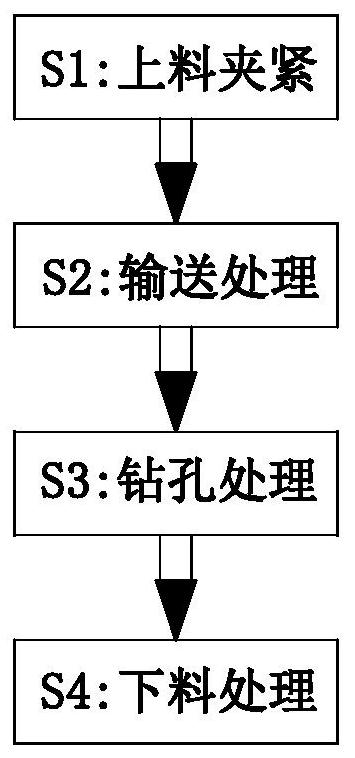

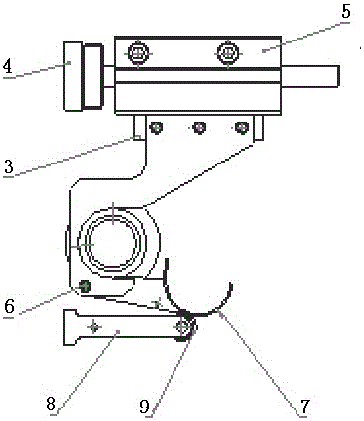

Casting machining forming method for air conditioner compressor end cover

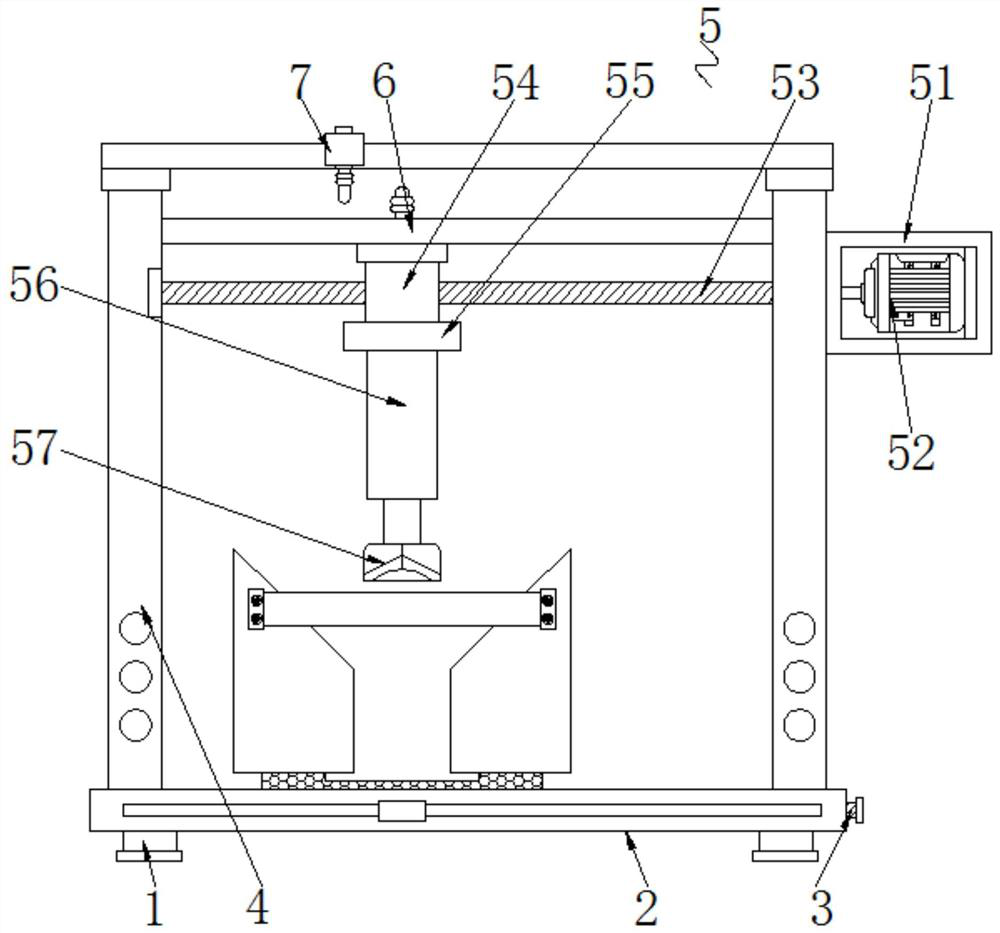

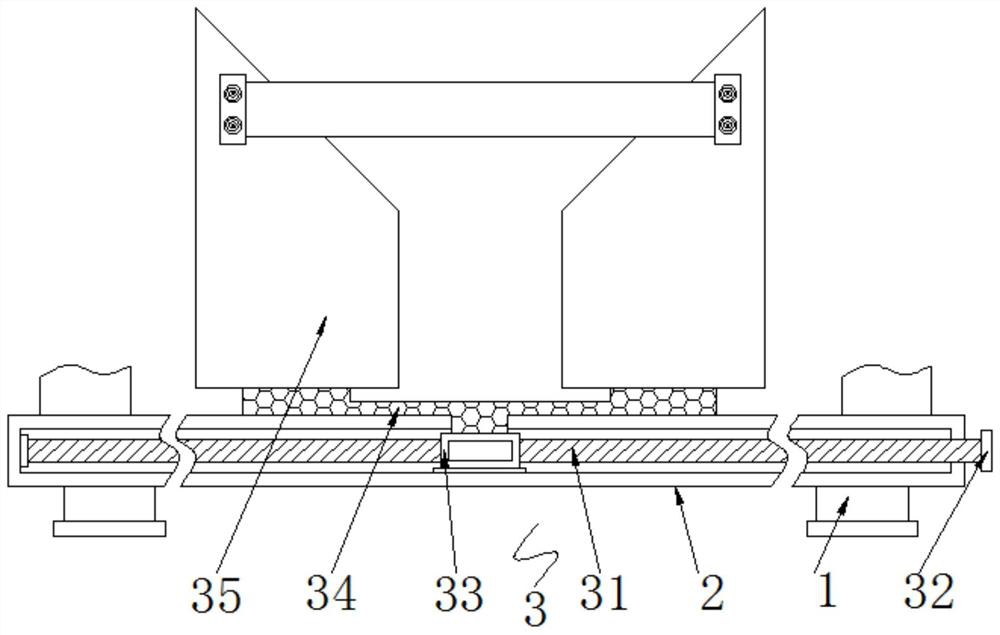

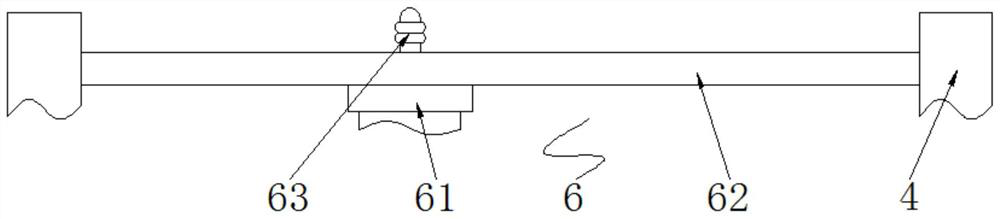

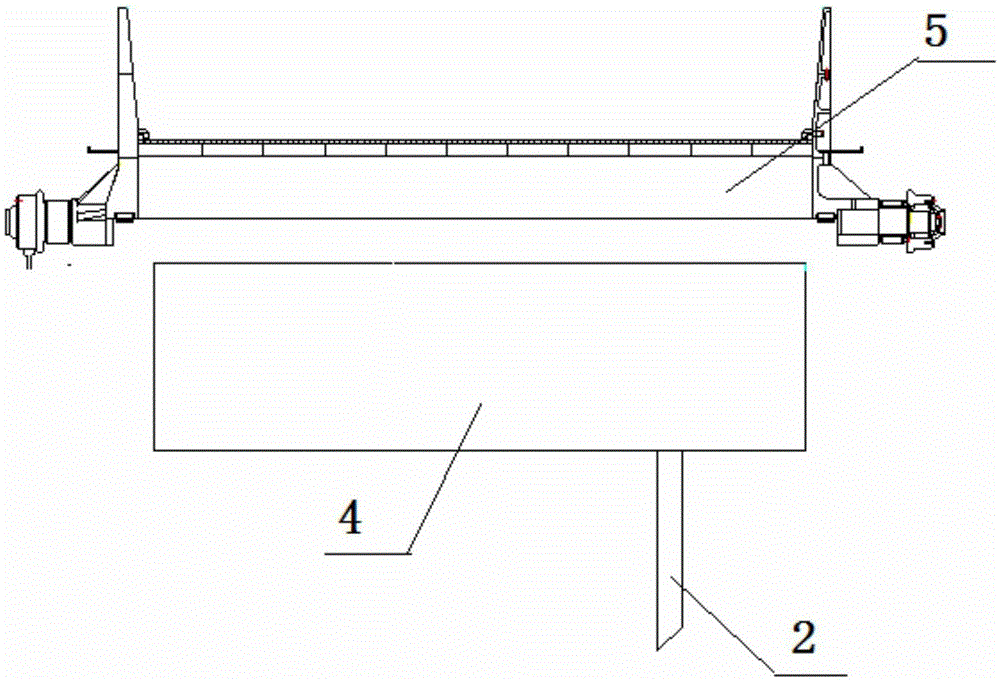

InactiveCN113427047AGood fixed effectImprove stabilityMetal working apparatusMaintainance and safety accessoriesPhysicsDrill hole

The invention relates to a casting machining forming method for an air conditioner compressor end cover. The casting machining forming method involves a workbench, a right-angled C-shaped plate, a feeding device and a drilling device. The casting machining forming method can solve the following problems that in the drilling process of an existing air conditioner compressor end cover, specifically, a, drilling treatment is conducted on the air conditioner compressor end cover through a single drill bit in a manual fixing mode, by means of the mode, the stability of the air conditioner compressor end cover in the drilling process cannot be guaranteed, in addition, only one hole can be drilled in each time of feeding of the drill bit, the machining efficiency is lower, the machining precision is poorer, and therefore the production quality of the air conditioner compressor end cover is reduced; and b, if chippings generated in the drilling process are not timely separated from the air conditioner compressor end cover, the chippings are extremely easy to attach to the inner wall of the hole diameter under the action of cooling liquid, so that the drilling precision is reduced, and the service life of the drill bit is further shortened.

Owner:武汉格律天创电气建设安装有限公司

Nursing bed for facilitating defecation

The invention discloses a nursing bed for facilitating defecation. The nursing bed comprises a bed plate and a bed enclosure arranged on the bed plate. The bed enclosure and the bed plate are fixedly connected through a hinge. One end of the bed plate is provided with an n-shaped groove, a base plate is arranged inside the groove and is the same as the groove in shapes, the size of the base plate is the same as that of the groove, supporting legs are arranged below the bed plate, a partition is arranged among the supporting legs and is provided with a cylinder used for driving the base plate to act, the seat of the cylinder is fixed to the partition, and the stretching rod of the cylinder is fixedly connected to the base plate. The nursing bed has the advantages that feet of a patient are fixed through a tie at first, then the base plate is descended through the cylinder, and finally a spittoon is placed on the base plate, so that the patient can defecate conveniently, excrement can be removed conveniently even falling on the base plate, the technical scheme is novel, and promotion and application of the nursing bed can be benefited.

Owner:李勃

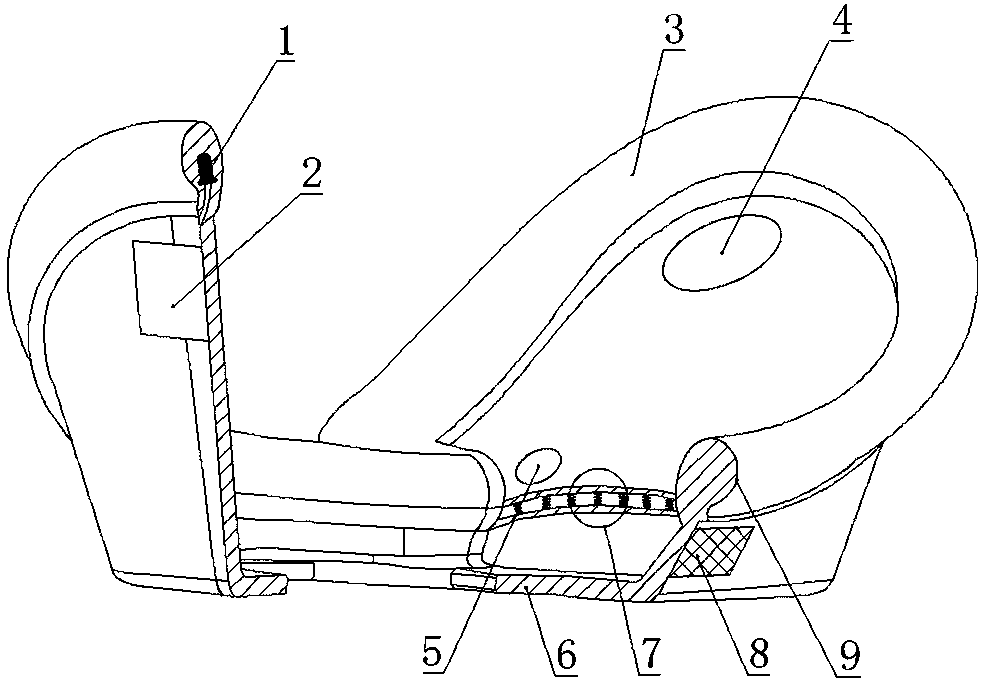

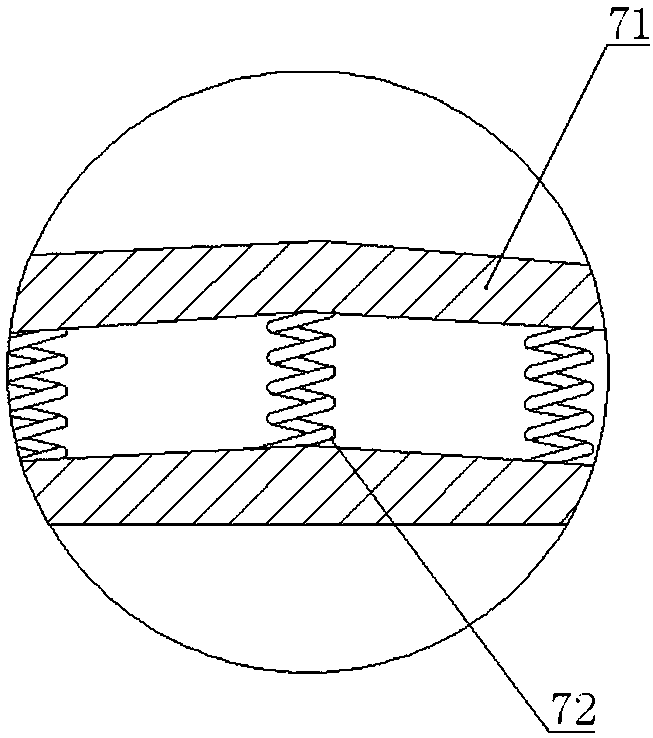

VR glasses protective sleeve

The invention discloses a VR glasses protective sleeve, including an elastic contact layer, a fluid driving device, a pressure sensor, a tian ying acupoint annular magnet, a temple annular magnet, anda VR glasses protection structure. The surface of one side of the elastic contact layer, close to a human face, is provided with a filling cavity. The filling cavity is filled with a fluid. The pressure sensor is mounted on the elastic contact layer. The fluid driving device is electrically connected with the pressure sensor. Through magnet therapy massage, the tian ying acupoint annular magnet relieves eye fatigue. The temple annular magnet relieves eye and brain fatigue through magnet therapy massage. The VR glasses protective structure comprises a glasses fitting plate and an elastic assembly. The glasses fitting plate is a movable structure and is fixedly connected with the elastic assembly. However, the glasses fitting plate does not contact and is not connected with the protective sleeve, and the glasses fitting plate and a VR glasses frame are abutted in use. Beneficial effect are that problems that a pair of VR glasses and a protective sleeve easily cause a face and eyes of auser fatigue are solved, and the protective sleeve has protection effect on VR glasses.

Owner:四川大学锦城学院

Stainless steel surface stud welding device

PendingCN112025049AEasy and fast weldingImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesStud weldingSS - Stainless steel

The invention relates to the technical field of stainless steel plate welding, and particularly discloses a stainless steel surface stud welding device. The device comprises a working plate, a squaregroove is formed in the top of the working plate, a hollowed-out plate is fixedly connected to the top of the working plate, baffles are fixedly connected to the top and the bottom of the working plate, each baffle is of an L-shaped structure, strip-shaped grooves are formed in the inner sides of the horizontal walls of the baffles, and sliding rails are installed on the inner side of the horizontal walls of the baffles. According to the stainless steel surface stud welding device, arranged positioning studs can be matched with arranged sliding rods so that the welding device can stably move above the working plate; meanwhile, the position of the welding device can be conveniently changed according to the position requirements of different steel plate welding bolts under the action of thesliding rails; the welding positions of the studs can be controlled according to the actual situation in the using process through the cooperation of a control panel; and stainless steel plates can beclamped according to the welding requirements of different stainless steel plates in the using process through an arranged clamp in cooperation with the arranged hollowed-out plate.

Owner:JIANGSU TONGLI MACHINERY

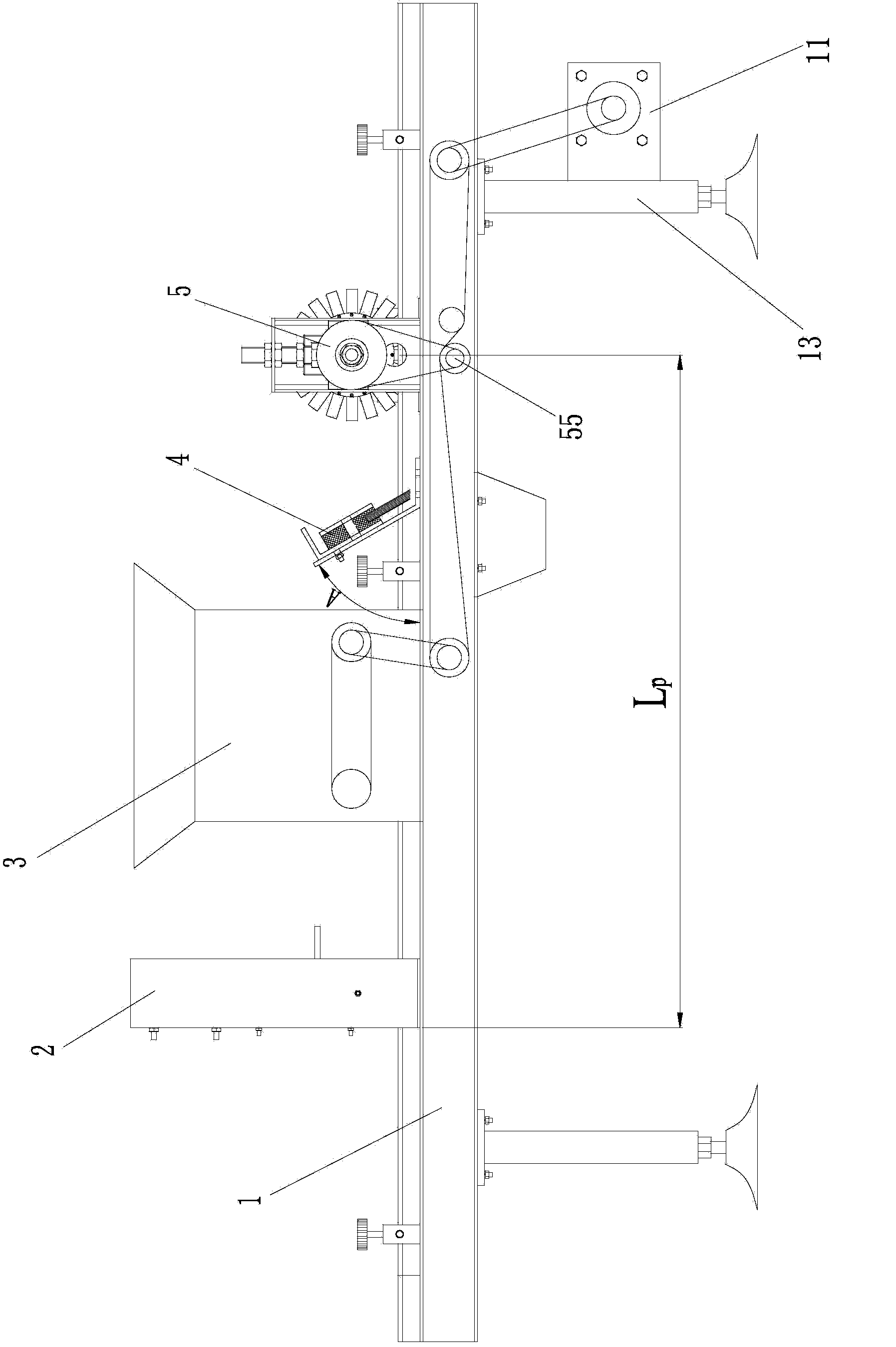

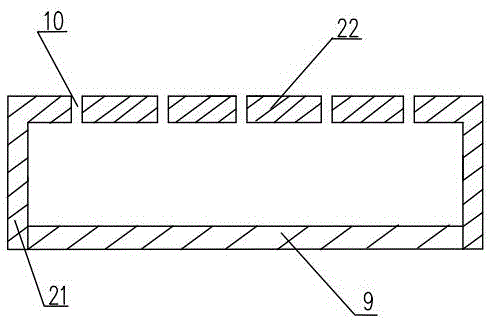

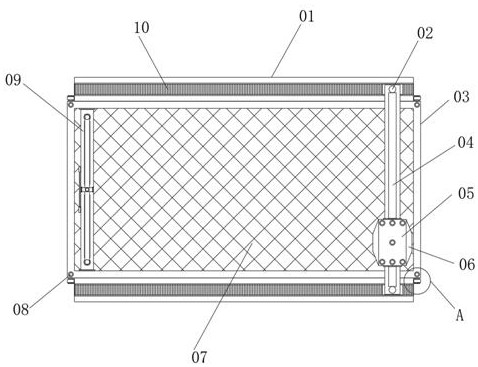

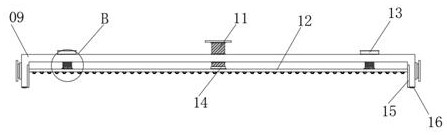

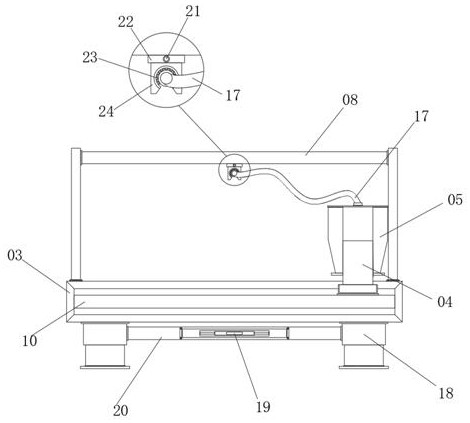

Combined double-layer composite seedling bed laying machine

PendingCN110199618AImprove laying efficiencyImprove laying effectRotary stirring mixersTransportation and packagingSeedlingPulp and paper industry

The invention discloses a combined double-layer composite seedling bed laying machine. A bottom soil discharging cavity, a seed paper discharging cavity and a surface soil discharging cavity are sequentially formed in a shell along a direction from one end to the other end, a seed paper unwinding device is arranged at the top of the shell and corresponds to the upper portion of the seed paper discharging cavity, a base discharging device is arranged outside the shell corresponding to one end of the bottom soil discharging cavity, multi-group rollers are arranged at the bottoms of two sides ofthe shell, the shell moves through the rollers along a rail, a base material coil is rotatably connected on the base discharging device, a seed paper roll is rotatably connected on the seed paper unwinding device, and the outer ends of the base material coil and the seed paper roll simultaneously penetrate the bottom of the shell downwards and are fixed to one end of the rail back to the base discharging device of the shell. From the structure, we can know that according to the combined double-layer composite seedling bed laying machine, double-layer composite seedling beds are automatically laid, and laying efficiency and laying effects are improved.

Owner:淮安汉德农业科技有限公司

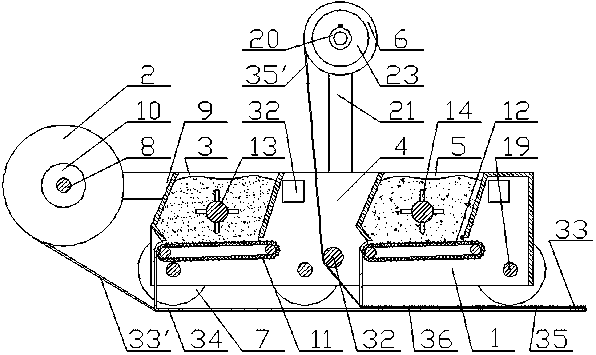

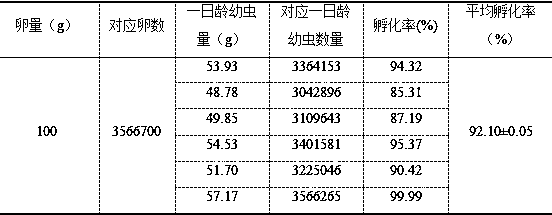

Incubation method for improving stratiomyiid eggs

The invention discloses an incubation method for improving stratiomyiid eggs. The number of eggs in each box is controlled to be 100-150 g, a thin layer is laid evenly, the phenomenon that egg massesare stacked to be thick is avoided, and the space of feeding boxes is not wasted; the breathability of the egg masses is better than that of stacked egg masses, and incubation of the egg masses is facilitated; incubation larvae can fall down from a mesh and a steel wire mesh in time, and the phenomenon that one-day-old small larvae eat the egg masses is avoided; starvation treatment is performed on the incubated one-day-old small larvae in a unified mode, after collection, the one-day-old small larvae are reared into the feeding boxes separately according to the needed density, unified charging is performed, and the phenomenon that the larvae are not consistent in size is avoided to the maximum extent possible.

Owner:浏阳市生旺种养专业合作社

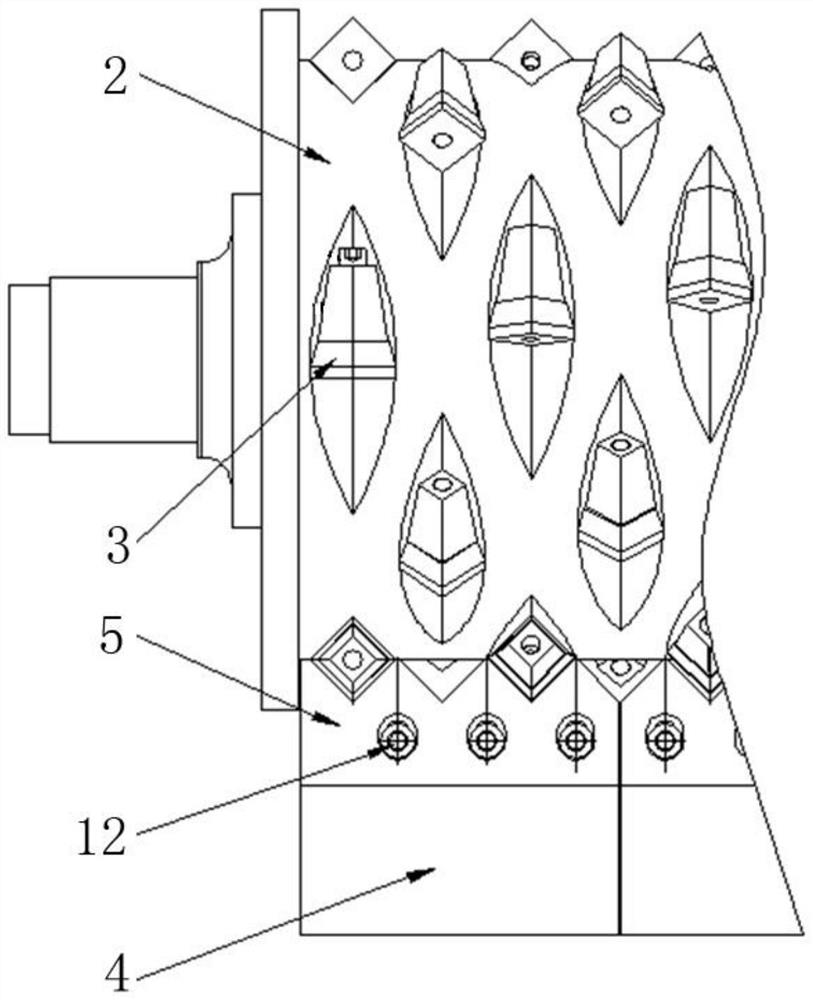

Shear crusher and cutter overload protection system thereof

PendingCN113560002AOverload implementationDrop in timeGrain treatmentsForeign matterStructural engineering

The invention discloses a cutter overload protection system comprising a cutter shaft rotationally arranged on a machine frame, a movable cutter arranged on the circumferential face of the cutter shaft, a cutter holder connected to the machine frame in a turnover mode, a fixed cutter arranged on the cutter holder and meshed with the movable cutter, and a first driving component arranged on the machine frame and connected with the cutter holder. When the pressure between the movable cutter and a fixed cutter is overloaded, the cutter holder is driven to overturn so that the movable cutter and the fixed cutter can be disengaged and a gap can be reserved for foreign matters to pass through. Therefore, according to the cutter overload protection system provided by the invention, when the pressure of the movable cutter and the fixed cutter is overloaded, the fixed cutter is separated from the movable cutter after being overturned along with the cutter holder through the driving effect of the first driving part on the cutter holder, the larger gap is reserved to make the foreign matters fall off in time, and the cutter overload protection of a shear crusher can be achieved. The cutters are prevented from being damaged during overload, equipment overload shutdown is avoided, and the production efficiency is improved. The invention further discloses the shear crusher.

Owner:CHONGQING GEARBOX

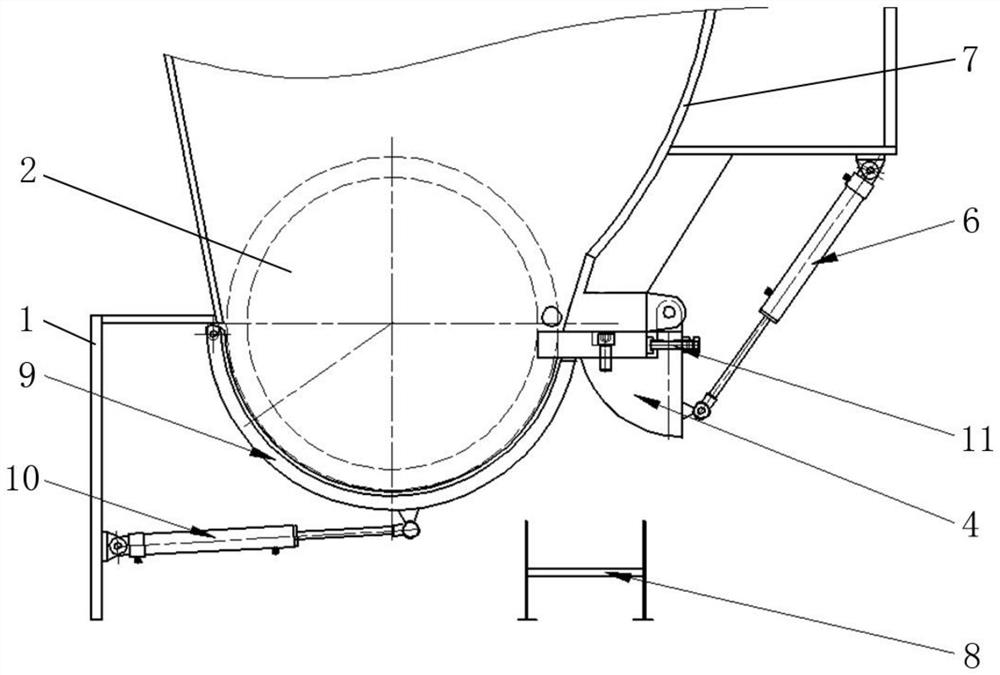

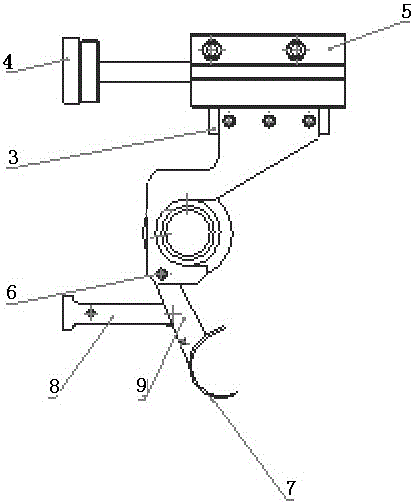

Automatic conduit moving and overturning mechanism

ActiveCN106025945AAvoid self-weight saggingSimple structureApparatus for removing/armouring cablesWire rodGuide tube

The invention relates to an automatic conduit moving and overturning mechanism which comprises a cylinder, a cylinder installing plate, a conduit, a conduit base, an installing plate, a rotary rod, a material guiding slot, a bearing and a bearing mounting base, wherein the conduit is fixed on the conduit base, the conduit base is installed on the installing plate, the cylinder is fixed on the cylinder installing plate, the material guiding slot passes through the rotary rod and is connected to the conduit base, the material guiding slot is supported by the bearing, and the bearing is installed on the bearing mounting base. The automatic conduit moving and overturning mechanism is simple in structure and reasonable in design, and switching of the conduit and the material guiding slot, wire delivery and front end peeling are realized through cylinder movement. The conduit is used for cutting total length, and the material guiding slot is used for peeling the rear end. A wire rod is dragged to prevent the wire rod from drooping due to deadweight. The material guiding slot is in two different states at two different positions. The wire rod is dragged during peeling the rear end, and peels peeled off from the wire rod can fall down timely. The tail end peeling length reaches 200mm.

Owner:徐州领君自动化设备有限公司

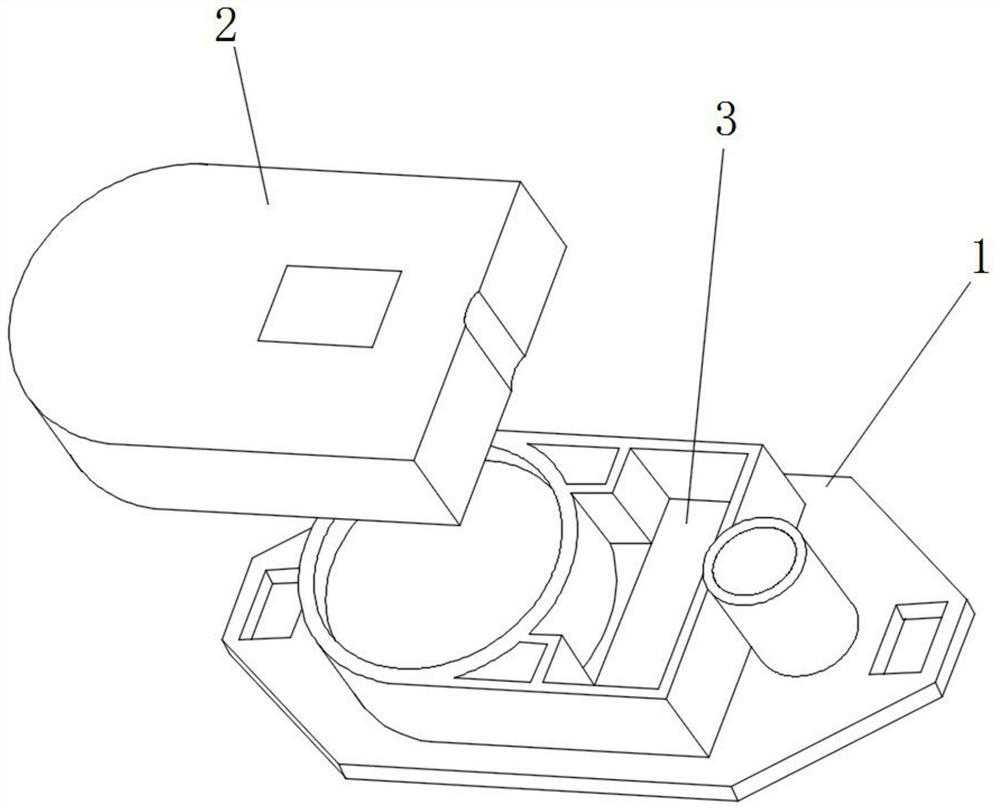

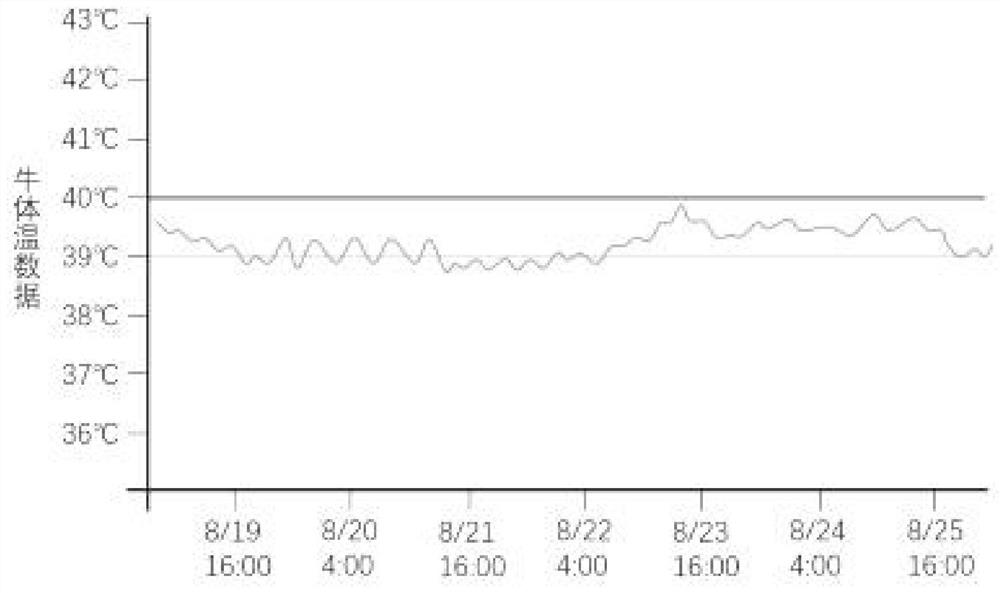

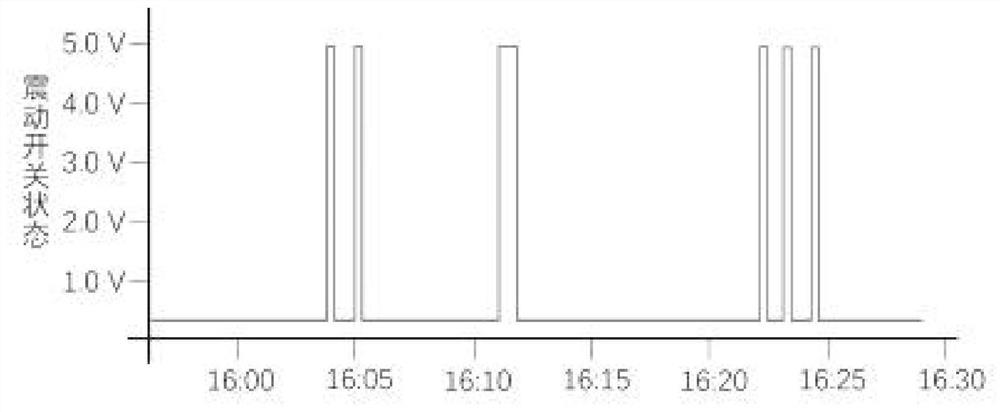

Multifunctional electronic ear tag for cattle

ActiveCN113973739ADrop in timeImprove sexual functionMeasurement devicesClimate change adaptationDigital signal processingEar tag

The invention discloses a multifunctional electronic ear tag for cattle, and relates to the technical field of electronic ear tags. The multifunctional electronic ear tag comprises a main tag and an auxiliary tag, a main control circuit board is fixedly mounted in the main tag, the auxiliary tag is mounted outside the main tag in a clamping manner, and a microprocessor, a Hall sensor, a temperature sensor and a vibration switch are mounted in the main control circuit board. A micro magnetic sheet is embedded in the auxiliary tag. According to the multifunctional electronic ear tag, the three problems of identity recognition, temperature measurement and abnormal behavior detection in a large-scale dairy cattle and beef cattle farm are solved by utilizing the sensor, digital signal processing and artificial intelligence technologies, so that the purposes of accurate management and labor cost reduction in the cattle breeding process are achieved. The micro magnetic sheet is matched with the Hall sensor, when the auxiliary tag falls off and the micro magnetic sheet is far away from the main control circuit board, the level changes, so that the falling of the ear tag can be sensed in time, and the functionality and the practicability of the ear tag are greatly improved.

Owner:ANHUI UNIVERSITY

Automatic decoking combustor for burning biomass fuel

The invention discloses an automatic decoking combustion chamber for burning biomass fuel, which belongs to the technical field of combustion equipment. It includes the movable grate plate set in the furnace and the fixed grate plate fixed in the furnace. The movable grate plate moves back and forth and frictionally cooperates with the fixed grate plate. All the movable grate plates move synchronously; the grate plate includes a grooved metal cover plate, and the legs of the metal cover plate are frictionally matched with the surface of the grate plate below it. A number of ventilation holes are arranged on the plate surface, and an air supply system for ventilating into the furnace through the ventilation holes is arranged under the grate plate, and a hopper, a material pushing plate and an igniter are also arranged. The invention fills the gap in the market, effectively solves the problem that the viscous jelly generated in the combustion process of biomass fuel blocks the ventilation holes of the grate plate, automatically decokes, balances the distribution of materials, ensures sufficient combustion, and has a simple structure and convenient operation.

Owner:张露纯

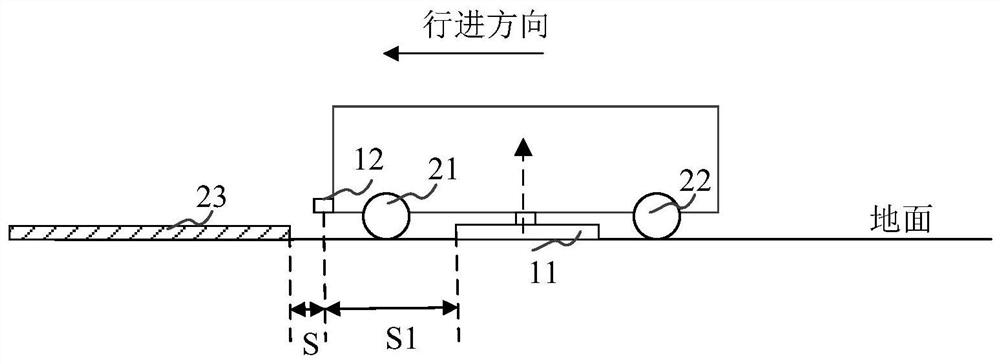

Automatic walking equipment and control method of automatic walking equipment

PendingCN114451814AEasy to cleanDrop in timeAutomatic obstacle detectionTravelling automatic controlAutomatic controlControl engineering

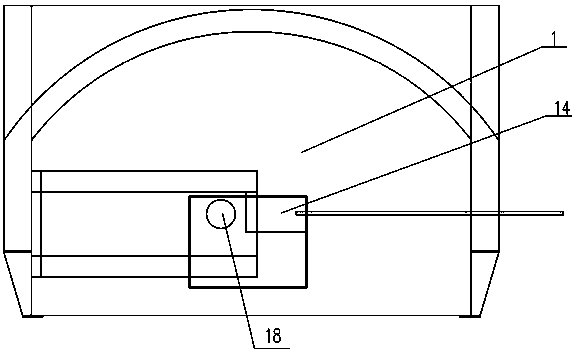

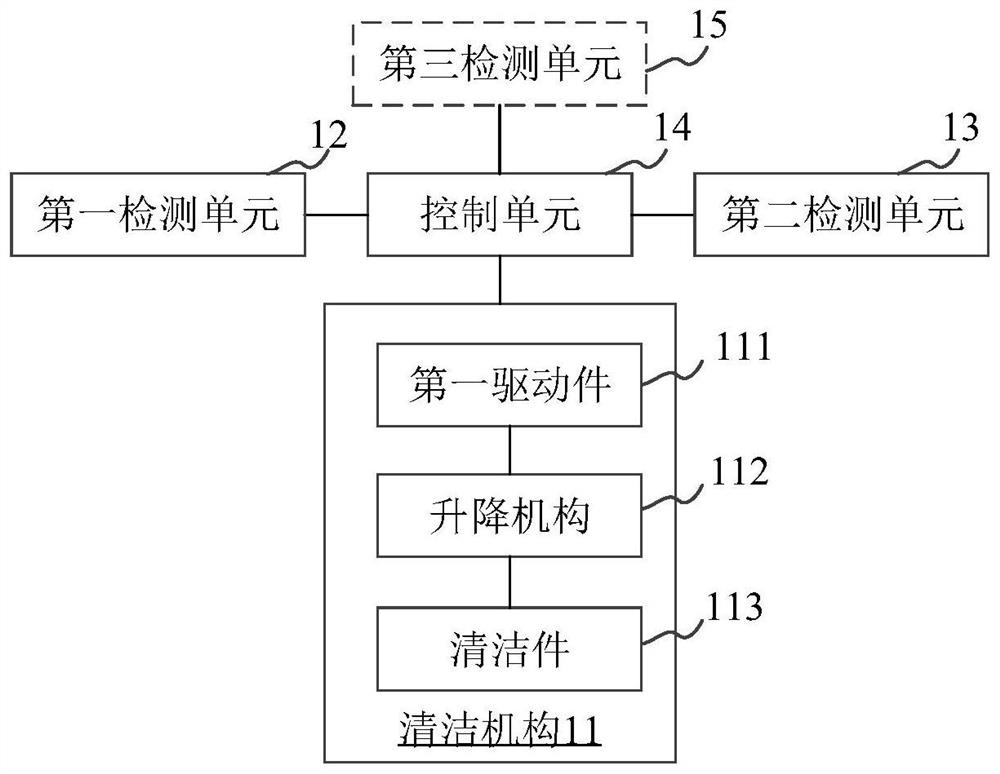

The invention discloses automatic walking equipment and a control method of the automatic walking equipment, and relates to the technical field of automatic control. The automatic walking equipment comprises a cleaning mechanism; the first detection unit is used for detecting an obstacle in front of the advancing direction to obtain a first detection result; the second detection unit is used for detecting obstacles behind the advancing direction to obtain a second detection result; the control unit is used for acquiring a first detection result and a second detection result; in the advancing process of the automatic walking equipment, if the first detection result meets a first preset rule, the cleaning mechanism is controlled to be lifted, so that the cleaning mechanism does not make contact with the obstacle; if the second detection result meets a second preset rule, the cleaning mechanism is controlled to descend, so that the cleaning mechanism makes contact with the ground and executes cleaning work; the problem that dust on a cleaning mechanism pollutes an obstacle due to the fact that the cleaning mechanism possibly makes contact with the obstacle in the obstacle crossing process of automatic walking equipment can be solved. And the cleaning effect of the automatic walking equipment is improved.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

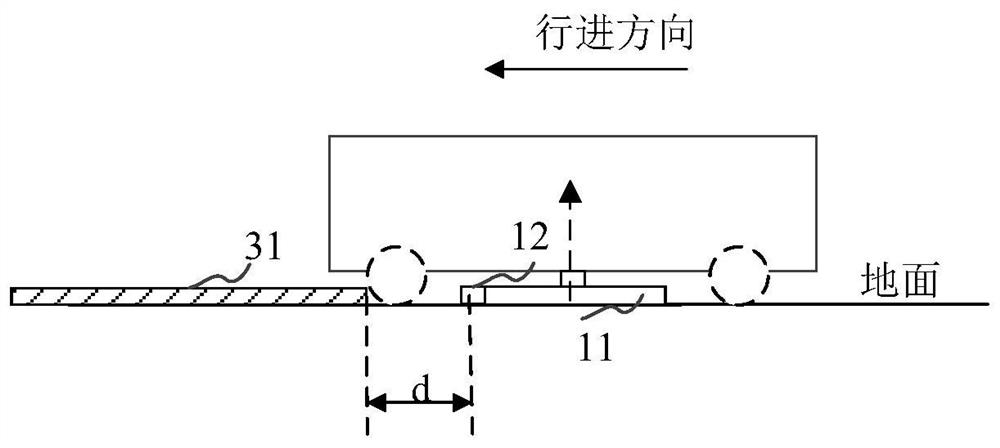

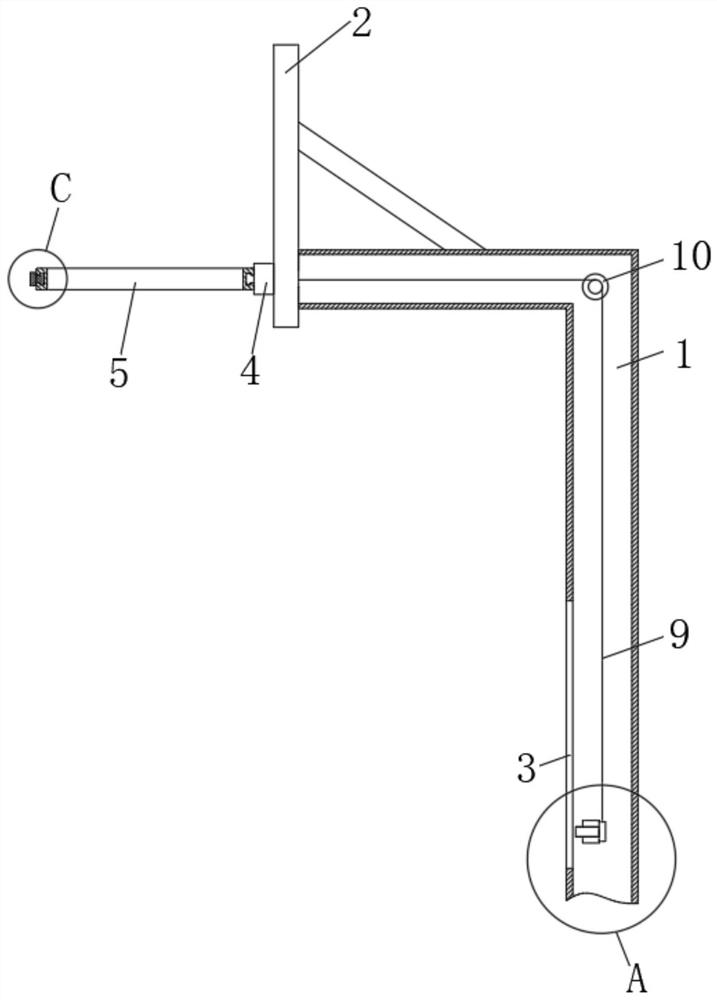

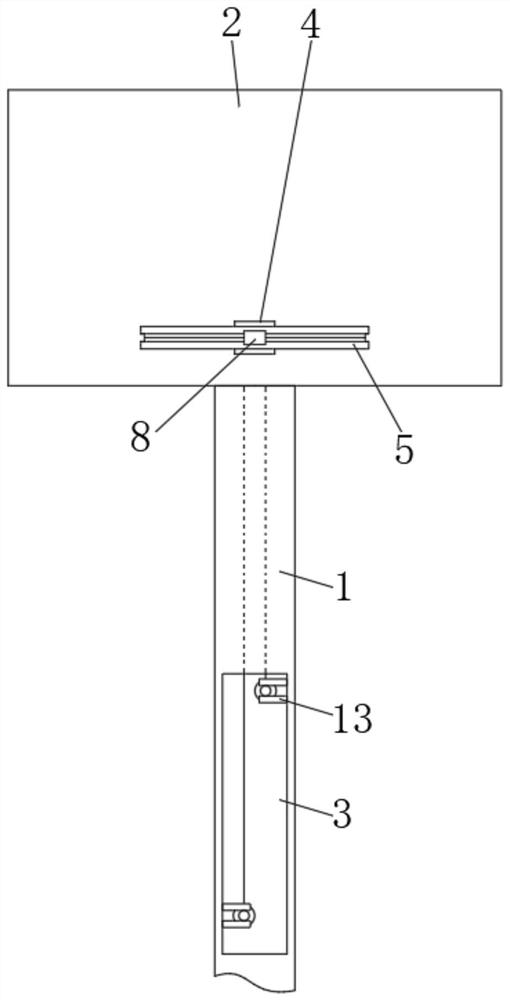

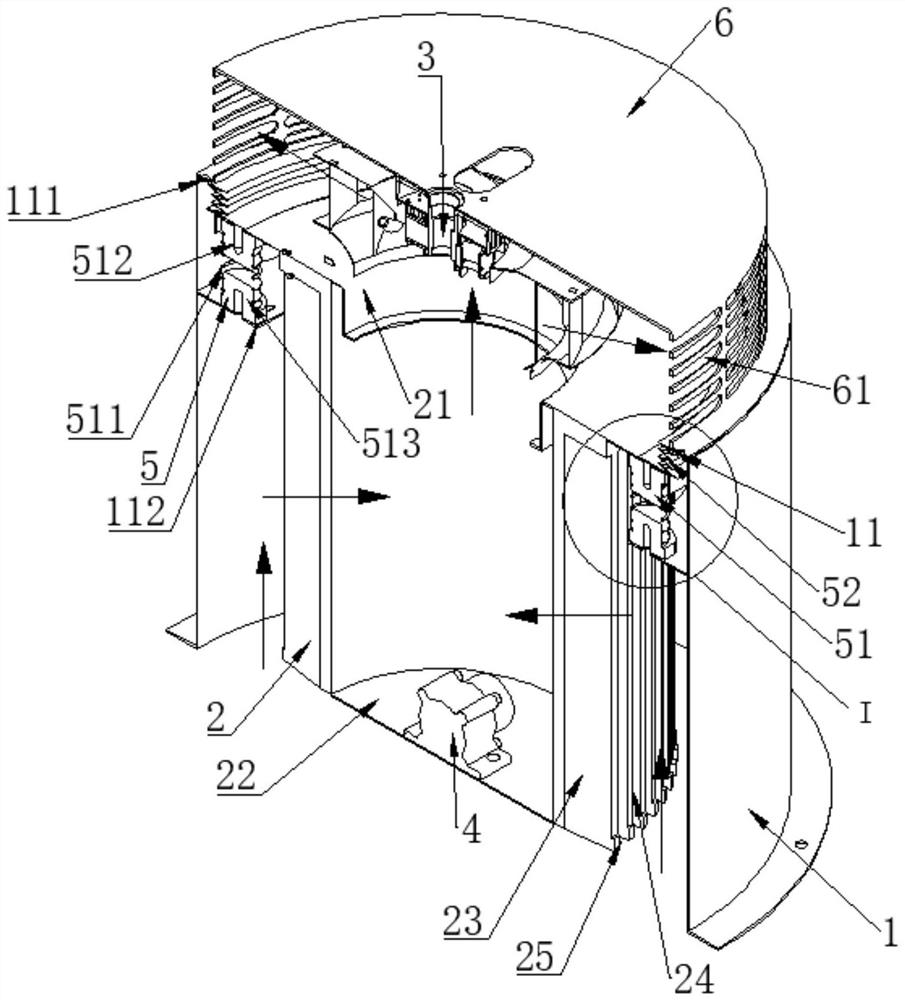

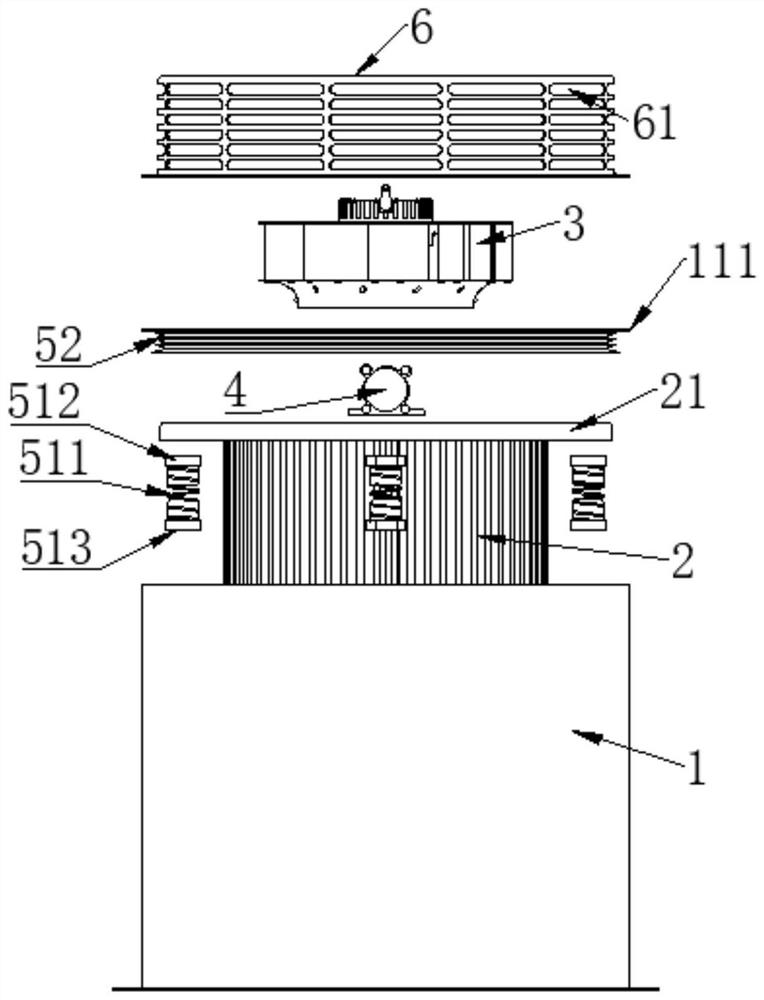

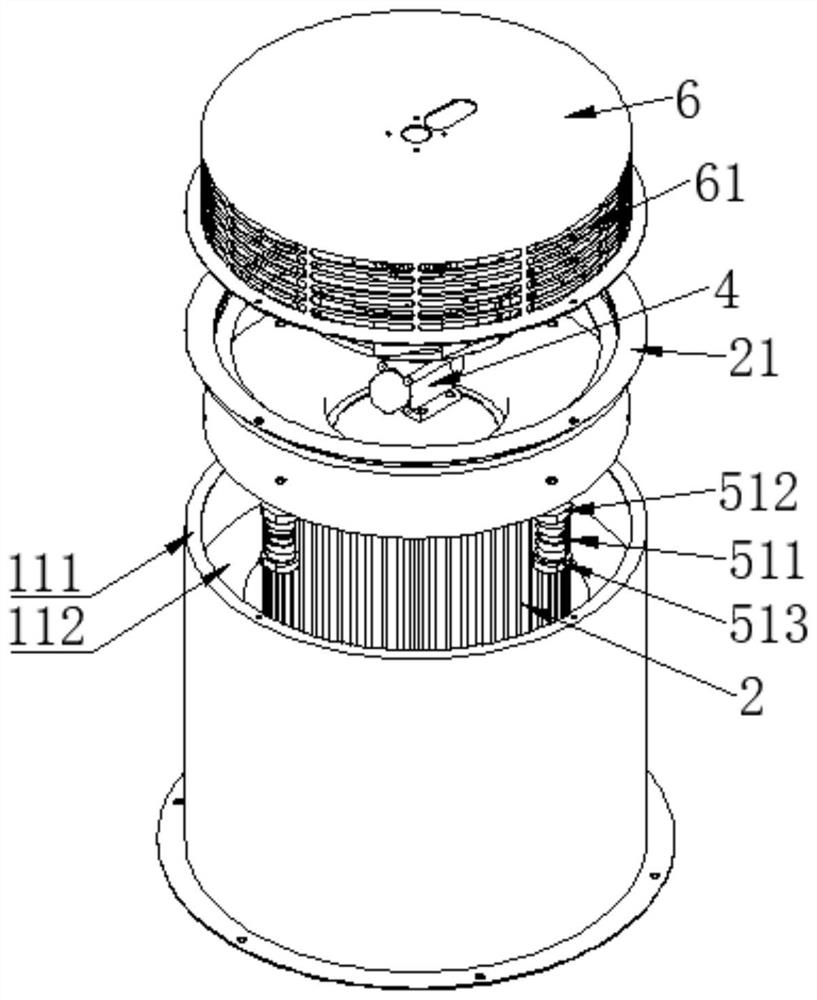

A basketball hoop for preventing ball jamming and its use method

ActiveCN109771918BDrop in timeMobile stable and reliableBall sportsStructural engineeringMechanical engineering

Owner:刘栩嘉

Dust filtering device and floor sweeping equipment

PendingCN114432812AImprove filtering effectDrop in timeDispersed particle filtrationTransportation and packagingProcess engineeringBrush device

The invention discloses a dust filtering device and sweeping equipment. The dust filtering device comprises a box body, a filter element assembly, an air extractor and a vibrator; the box body is cylindrical; the filter element assembly is arranged in the box body and is in a cylinder shape with a closed lower part, the upper part of the filter element assembly is hermetically connected with the upper part of the box body, an air inlet area is formed between the box body and the filter element assembly, and an inner cavity of the filter element assembly forms an air outlet area; the air extractor is located above the filter element and generates negative pressure in an inner cavity of the filter element, so that dust-containing gas is sucked into the air outlet area through the peripheral wall, penetrating through the air inlet area, of the filter element; and the vibrator is mounted at the bottom of the filter element. The sweeping equipment comprises a chassis, a garbage can and a rolling brush device, a chassis; the dustbin is arranged behind the chassis; the rolling brush device is arranged below the chassis and provided with a garbage outlet, and the garbage outlet is communicated with the garbage can; the dust filtering device is arranged on the chassis, and an air inlet area between the box body and the filter element is communicated with the garbage can.

Owner:广东美房智高机器人有限公司

High-repeatability position identification method and device for laser diode chip

PendingCN112349630AFor quick maintenancePrevent self-slipSemiconductor laser structural detailsSemiconductor/solid-state device manufacturingMechanical engineeringPhysics

The invention discloses a high-repeatability position identification method for a laser diode chip. The method specifically comprises the following steps of 1, basic positioning operation, 2, advancedpositioning operation and 3, the basic operation of a device, and relates to the technical field of chips. According to the high-repeatability position identification method and device for the laserdiode chip, the device can be manually adjusted by a worker, a manual screw can drive a position display block to move to an accurate position, and meanwhile, a certain angle is formed in the surfaceof a limiting block, so that the chip can conveniently fall onto the surface of the limiting block in time when a working telescopic rod extends, and can automatically fall onto the surface of the limiting block along with the limiting block; and through the arrangement of a position marking device, the whole device can drive a positioning head to move to a related accurate position by moving a horizontal top plate leftwards and rightwards, and a clamping plate in the device can be pushed by a reset spring to be tightly fixed to the surface of the horizontal top plate, so that the operation accuracy of the device is improved.

Owner:武汉智汇芯科技有限公司

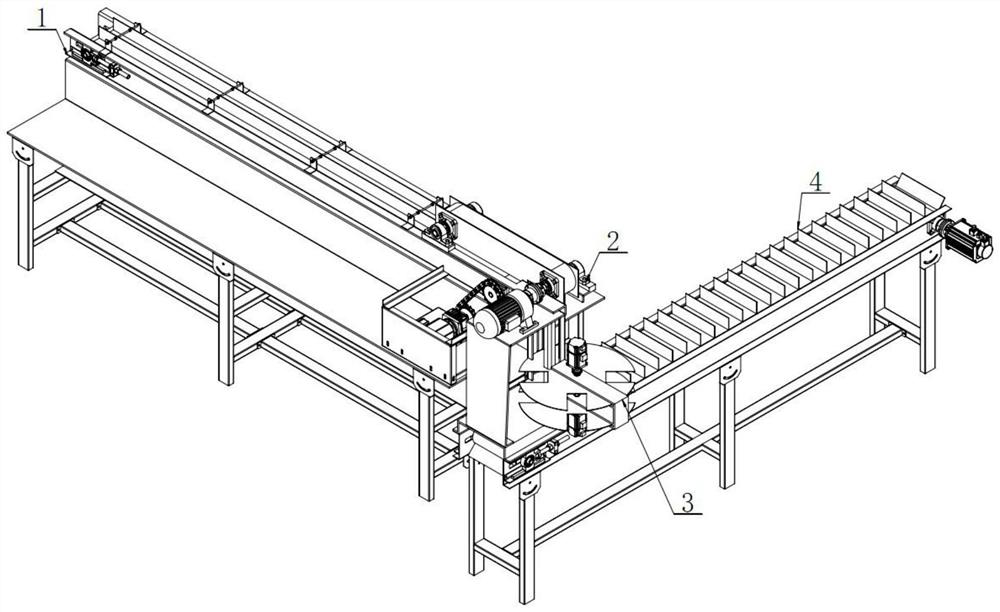

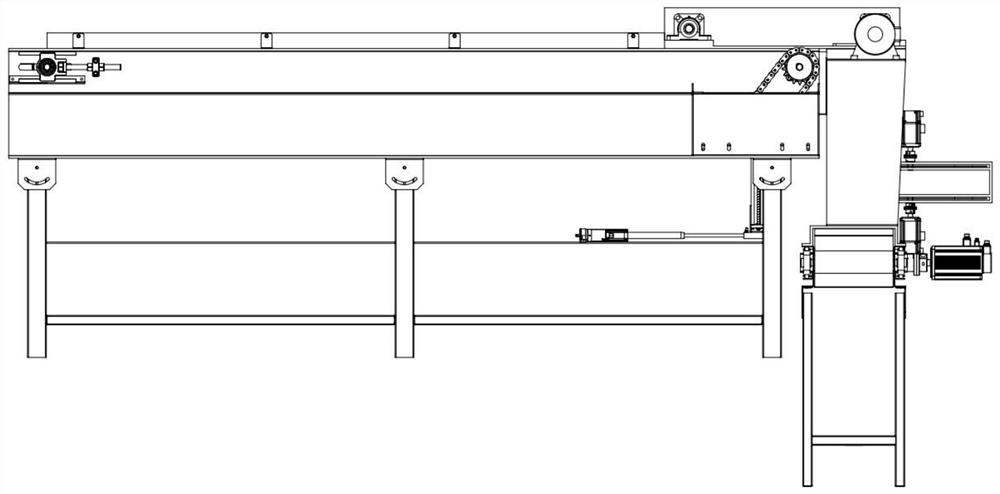

Material removal device for sintering machine trolley

The invention discloses a material removal device for a sintering machine trolley. The material removal device comprises pressure containers (1), conveying pipelines (1), blowing heads (3) and a blowing device (4). The pressure containers (1) are communicated with the blowing device (4) through the conveying pipelines (2). The blowing heads (3) are arranged on the blowing device (4) and face the upper surface of the sintering machine trolley (5). The material removal device for the sintering machine trolley solves the problem that sinter particles cannot fall off from a sintering machine trolley in time in the prior art and guarantees that blown sinter particles fall off from the trolley in time.

Owner:WUHU XINXING DUCTILE IRON PIPES

A non-clogging stacking mechanism for drug blister plates and its application method

ActiveCN111674632BAvoid leaningRealize flexible feedingPackaging automatic controlStacking articlesClassical mechanicsEngineering

The invention discloses a drug blister plate non-blocking stacking mechanism and its use method, comprising an extrusion mechanism, a storage bin, an adjustment plate, a lead screw linear module and an electric push rod. Above the output end of the mechanism, the storage bin is a frame structure with openings at both ends, the upper end is close to the output end of the feeding conveying mechanism, the lower end is located above the feeding end of the stacking conveying mechanism, the adjusting plate is a right-angle Z-shaped structure, and one end is movable into the storage The storage bin in the bin and extending into one side is provided with a vertical strip hole, and the other end is fixedly connected to the sliding block of the lead screw linear module through a flange plate, and the lead screw linear module is installed vertically on the slide plate. The slide plate is placed on the flat plate on the feeding frame of the feeding conveying mechanism, and is connected with the end of the push-pull rod of the electric push rod. the transverse gap. The invention realizes avoiding rollover and blockage when the blister plate falls, and realizes flexible discharging.

Owner:GUIZHOU UNIV

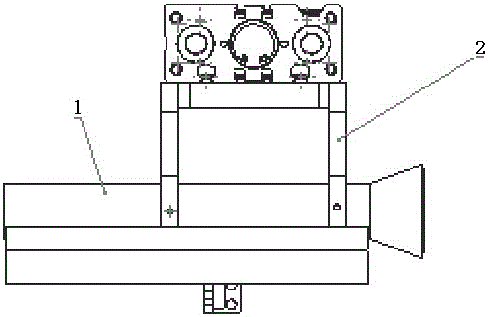

Subsoil compaction device of rice precision seedling seeding machine

The invention discloses a bottom soil compacting device of a rice seedling precisely-raising planter. The bottom soil compacting device comprises a frame, a hole aligning mechanism and a bottom soil compacting mechanism, wherein the hole aligning mechanism and the bottom soil compacting mechanism are arranged on the frame, and the frame is provided with a driving motor and a seedling tray conveying mechanism. The hole aligning mechanism comprises a limit baffle, a stepping motor, a limiting travel switch and a tray feeding travel switch; the bottom soil compacting mechanism comprises a compacting roller shaft with radially-extending roller fingers and a roller finger position detecting mechanism. According to the bottom soil compacting device of the rice seedling precisely-raising planter, the travel of seedling trays and the roller fingers are limited, the limit travel switch, the tray feeding travel switch and a roller finger position detector control seedling tray feeding and the positions of the finger rollers respectively, meanwhile, the linear speed and the rotation direction of the compacting roller shaft are identical to the seedling tray conveying speed and the seedling tray conveying direction of the seedling tray conveying mechanism, so that when the seedling trays move to the positions of the roller fingers, the roller fingers can be accurately inserted into the holes of the seedling trays to compact soil. The bottom soil compacting device of the rice seedling precisely-raising planter is reliable in operation, high in efficiency and wide in market application and popularization prospect.

Owner:SOUTH CHINA AGRI UNIV

Mechanical steel bar equal-length cutting equipment

ActiveCN111390065AEasy to operateLarge single workloadConveyor partsElectric machineryStructural engineering

The invention relates to the technical field of steel bar manufacturing equipment, and discloses mechanical steel bar equal-length cutting equipment. The mechanical steel bar equal-length cutting equipment comprises a pipe body, a collection trough, a first motor, a second motor, steel bar input holes and cutting knives. The multiple sets of transverse steel bar input holes at equal distance are formed in the outer side of the pipe body. Multiple sets of falling openings with lengths sequentially increased are formed on the steel bar input holes from right to left. Cutting troughs are downwards formed in the positions, between the falling openings, in the steel bar input holes. The cutting knives are rotationally connected in the cutting troughs. One set of cutting knives with diameters and sizes being telescopic are arranged in each knife cavity. The inner side of each cutting knife leftwards communicates with four sets of identical inclined telescopic rods, the left ends of the telescopic rods of each cutting knife are fixedly connected with a transverse piston rod through a connecting plate, air cylinders fixed in rotating shaft pipes are arranged on the left sides of the pistonrods, and the interiors of the cutting knives are connected through multiple sets of telescopic plates at equal distance. The mechanical steel bar equal-length cutting equipment has the advantages that the workloads of a single time are large, the automation degree is high, and the work efficiency is high.

Owner:陈思涵

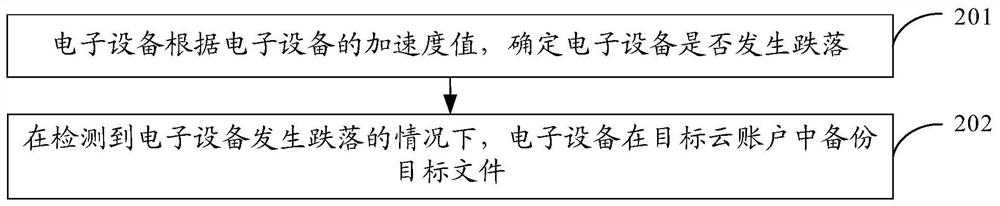

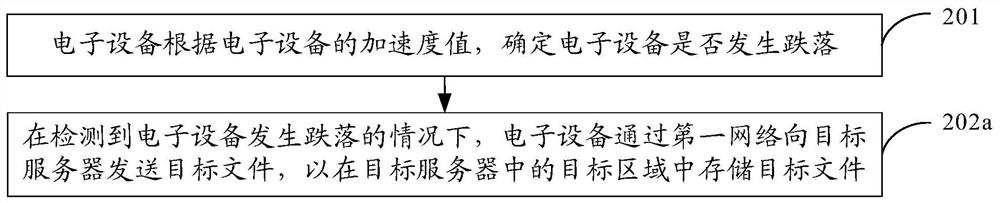

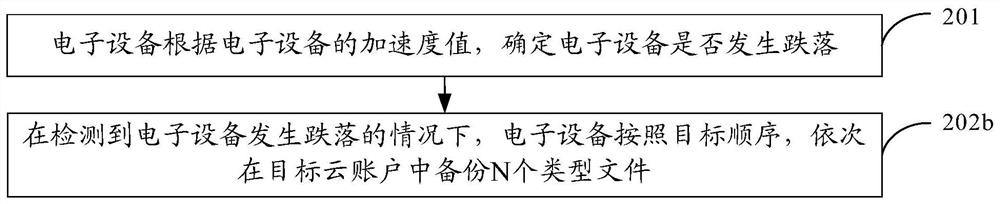

File backup method and device and electronic equipment

InactiveCN111917917ADrop in timeAvoid lossSubstation equipmentTransmissionSoftware engineeringObject file

The invention discloses a file backup method and device and electronic equipment, and belongs to the technical field of communication. The problem that file data in the electronic equipment is lost when the electronic equipment falls off and is damaged can be solved. The method comprises the steps of determining whether the electronic equipment falls or not according to an acceleration value of the electronic equipment; when detecting that the electronic equipment falls off, backing up a target file in a target cloud account, wherein the target cloud account is an account used for file backupin the electronic equipment, and the target file is a file which is not backed up in the target cloud account in the electronic equipment. The embodiment of the invention is applied to a file backup process of the electronic equipment.

Owner:VIVO MOBILE COMM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com