Recycle production line and recycle technology of PET (Polyethylene Terephthalate) bottles

A production line and bottle body technology, applied in the plastic recycling production line and process field, can solve the problems of impurity precipitation, affecting cleaning effect, small impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

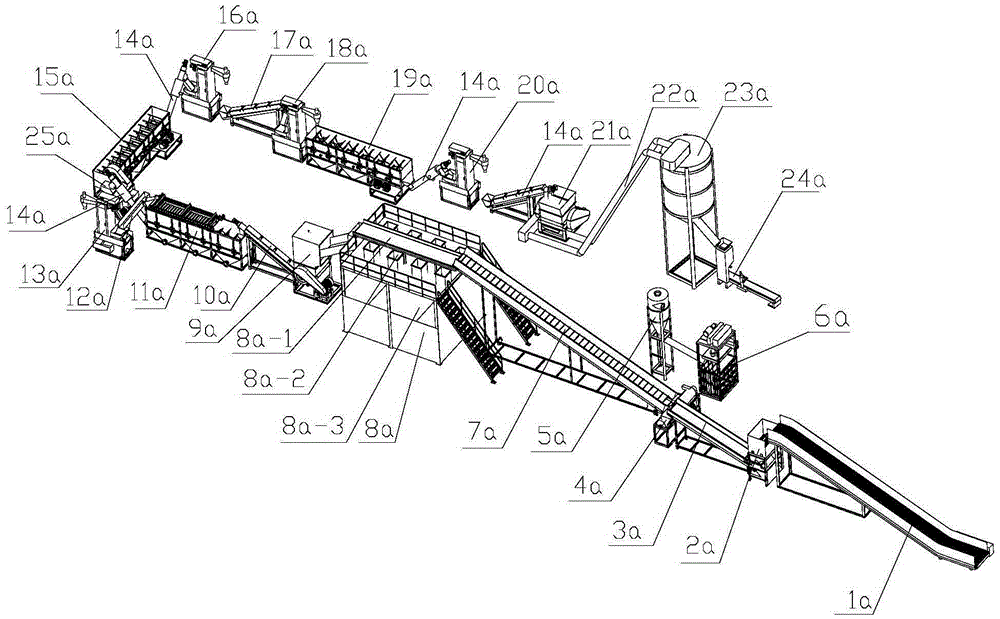

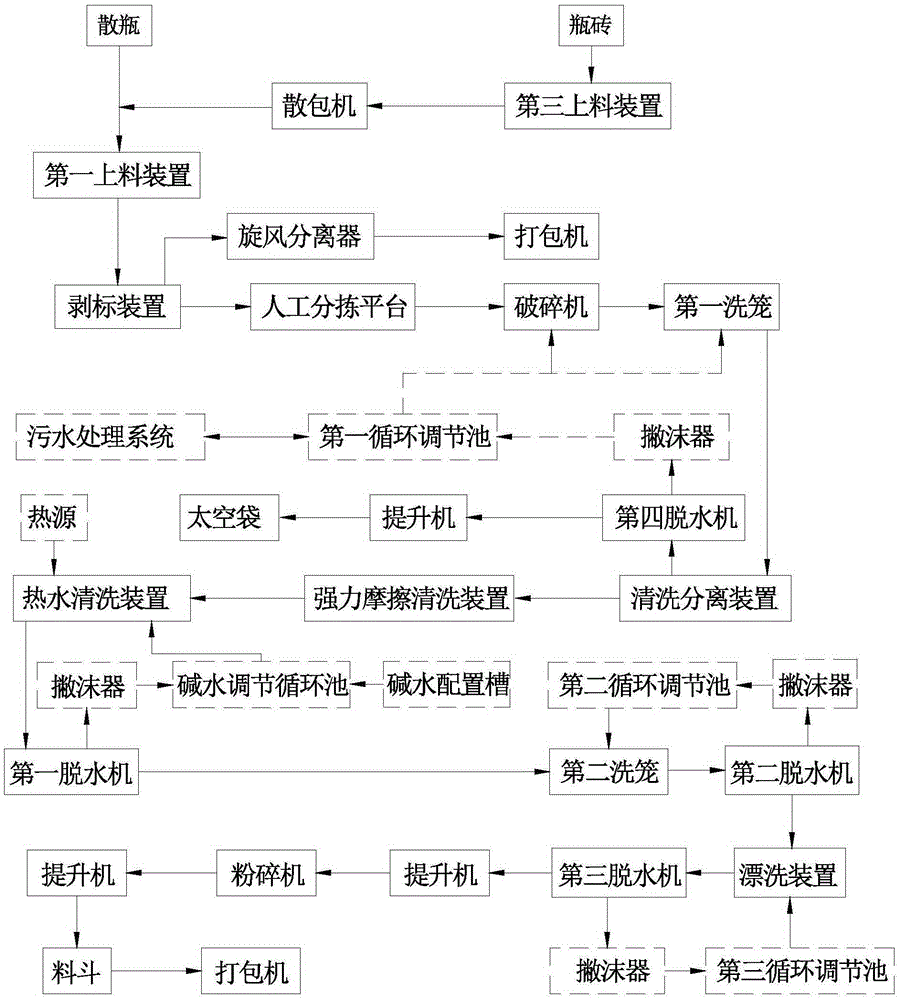

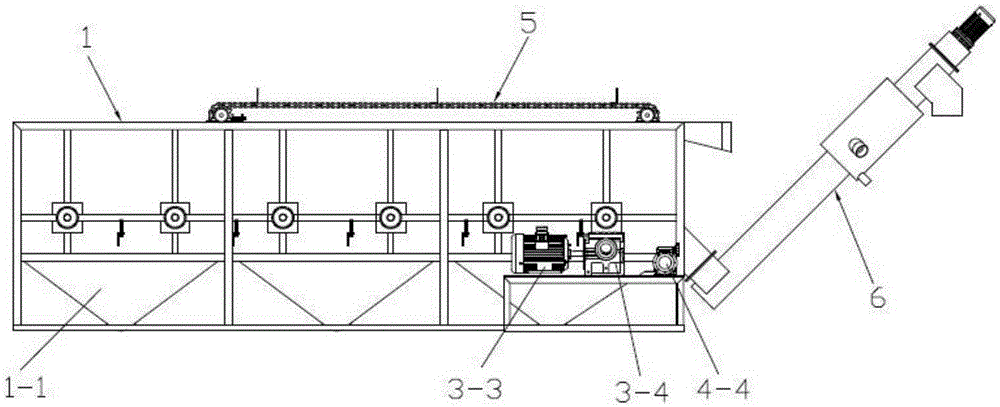

[0052] see figure 1 and figure 2 , the PET bottle recycling production line of the present invention comprises the 3rd feeding device 1a that connects successively, unpacking machine 2a, the first feeding device 3a, label stripping device 4a, the second feeding device 7a, manual sorting platform 8a, crusher 9a, first washing cage 10a, cleaning and separating device 11a, strong friction cleaning device 25a, hot water cleaning device 15a, first dehydrator 16a, second washing cage 17a, second dehydrator 18a, rinsing device 19a, third dehydration machine 20a, elevator 14a, pulverizer 21a, pipe chain conveyor 22a, hopper 23a and baler 24a. in:

[0053] The third feeding device 1a and the unpacking machine 2a are used to break up the bundled materials: some recycled PET bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com