Mechanical steel bar equal-length cutting equipment

A technology of cutting equipment and steel bars, applied in the field of long cutting equipment, can solve the problems of low degree of automation, low work efficiency, insufficient control of cutting blades, etc., and achieve the effect of high degree of automation, large single workload and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

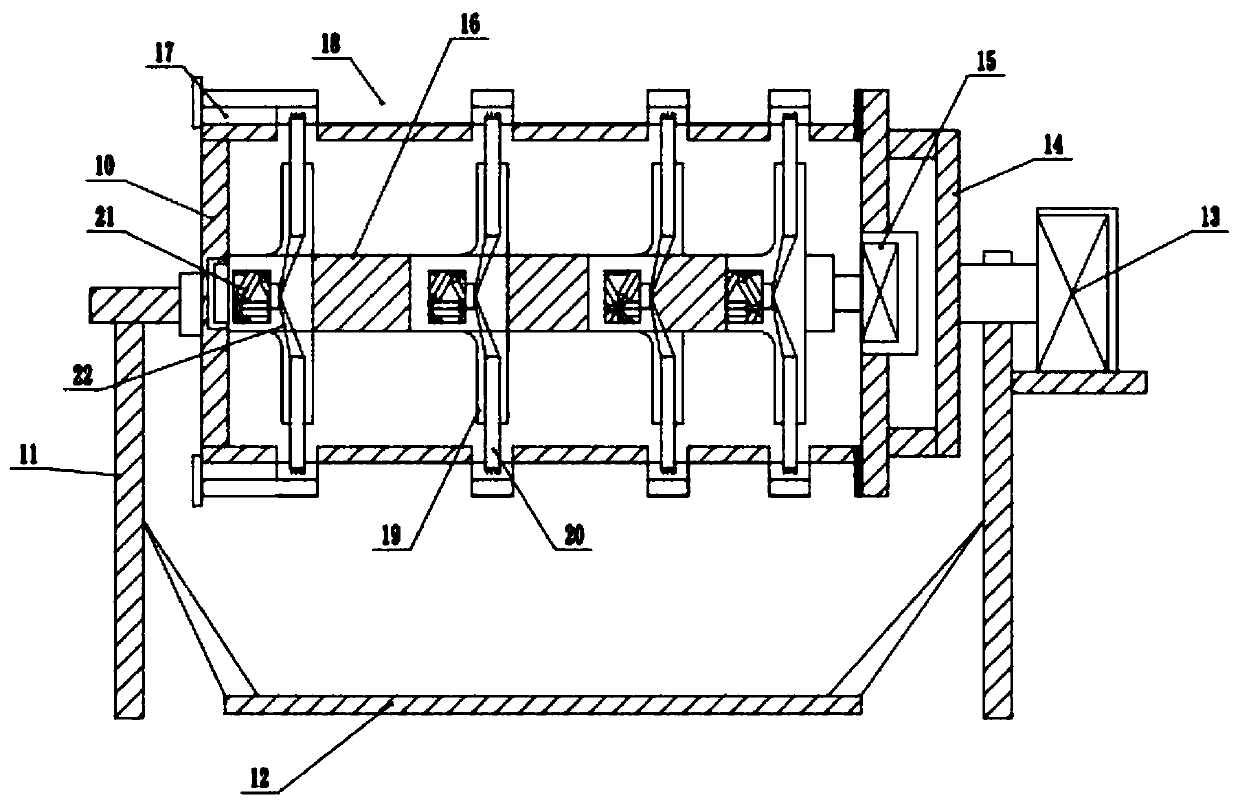

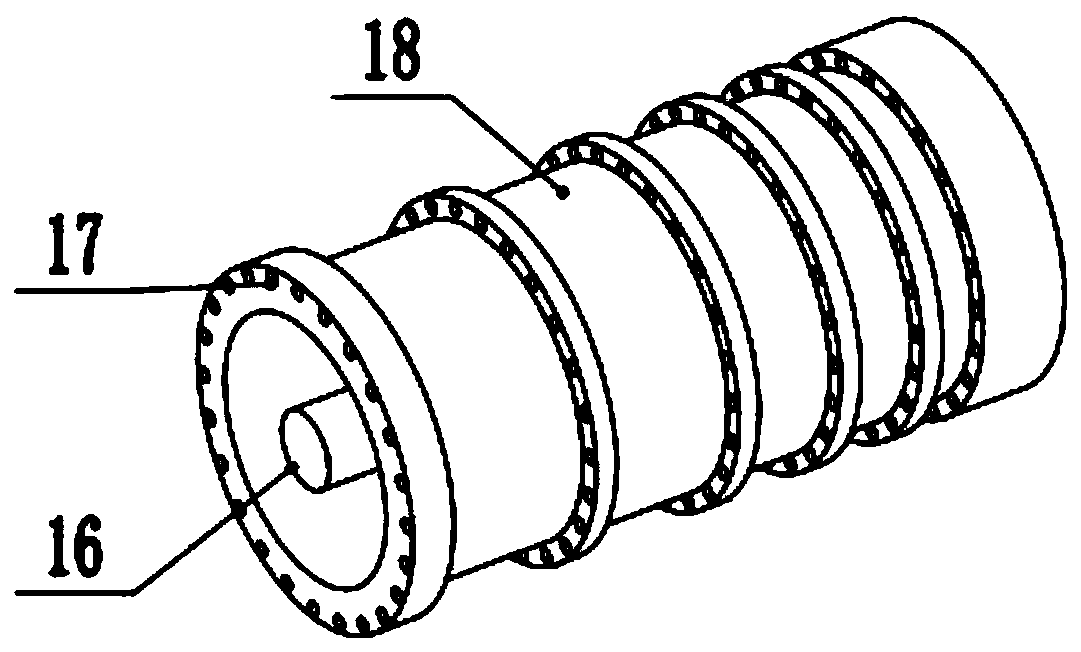

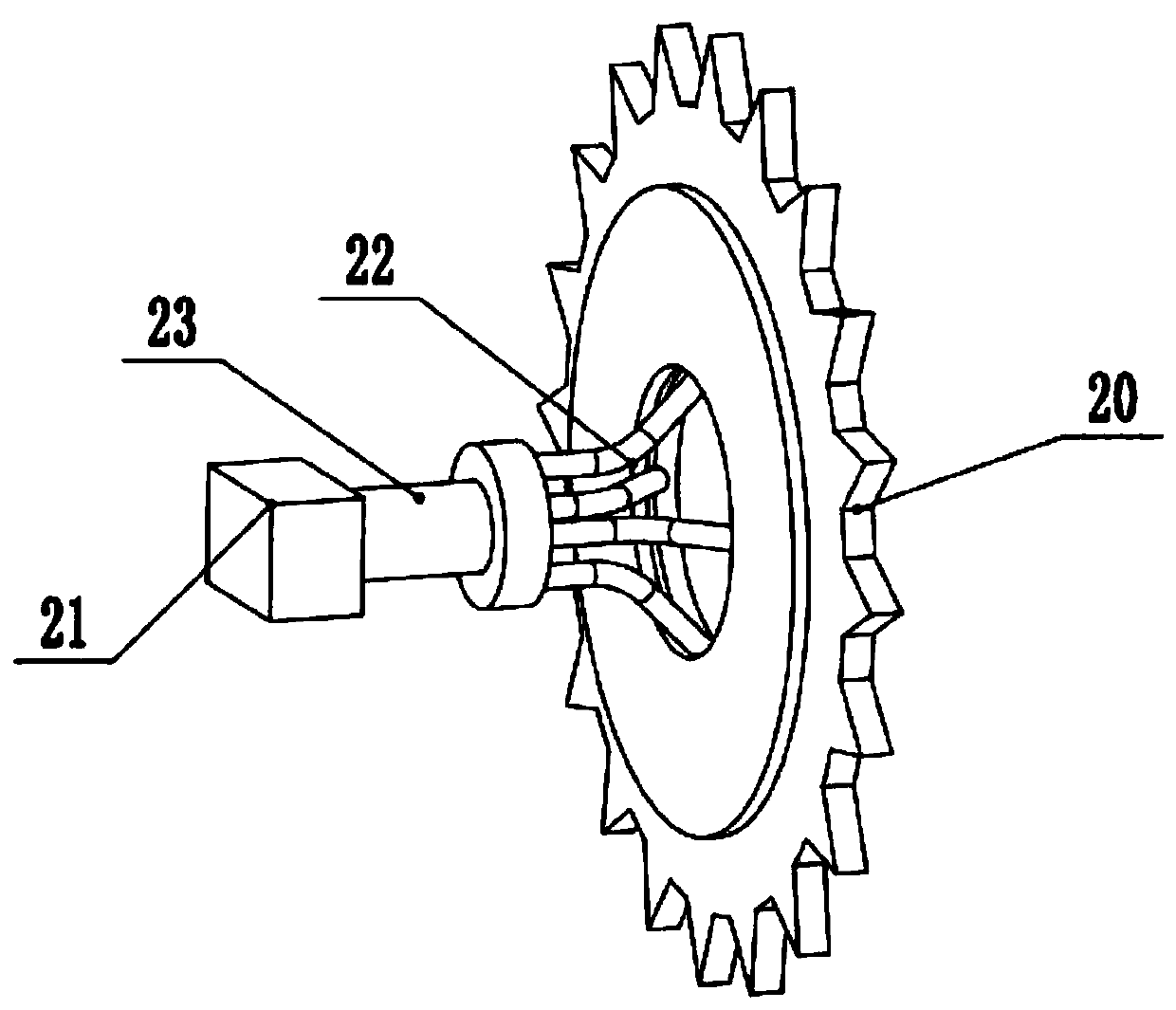

[0023] See Figure 1-3 , A mechanical steel bar isometric cutting equipment, including a pipe body 10, a collection tank 12, a first motor 13, a second motor 15, a steel bar input hole 17, a cutting knife 20; the left side of the pipe body 10 is connected with a rotating The bottom of the rotating seat is supported by the bracket 11. The right side of the tube body 10 is fixedly installed with a set of mounting brackets 14 in a U-shaped structure, and the middle of the right side of the mounting bracket 14 is fixedly installed with the tube core of the tube body 10. The rotating rods overlap each other. The right end of the rotating rod is rotatably connected with the first motor 13, the middle of the rotating rod is supported by the vertical bracket 11, and the bottom of the first motor 13 is supported by the support plate fixed on the bracket 11 at the left end. . A protective cover is provided on the outside of the first motor 13, and a sound insulation layer is provided on...

Embodiment 2

[0028] On the basis of the first embodiment, the inner side of the knife cavity 19 is pasted with a layer of rubber pad. When the telescopic rod 22 pulls the cutting knife 20 to expand, it is inevitable that the cutting knife 20 is arranged inside the knife cavity 19 It will come into contact with the knife cavity 19, and by providing a rubber pad, the cutting knife 20 and the knife cavity 19 can be prevented from being worn out during contact.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com