Agglomerated fertilizer de-agglomerating facility for garden fertilizing

An agglomeration and fertilizer technology, which is applied in the field of agglomerated fertilizer deblocking equipment for garden fertilization, can solve the problems of unevenness, large fertilizer, inconsistent plant growth state, etc., and achieve the effect of uniform crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

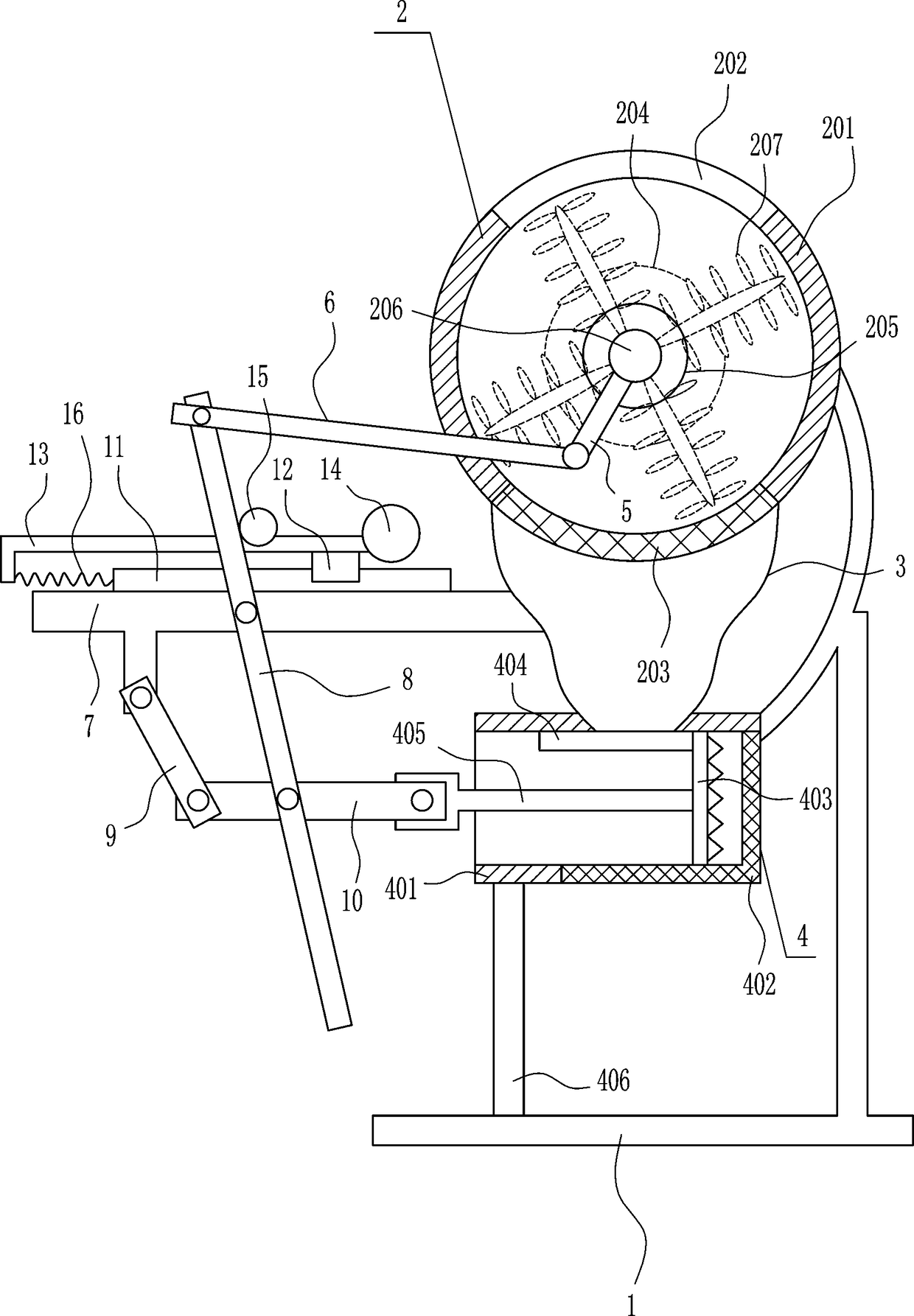

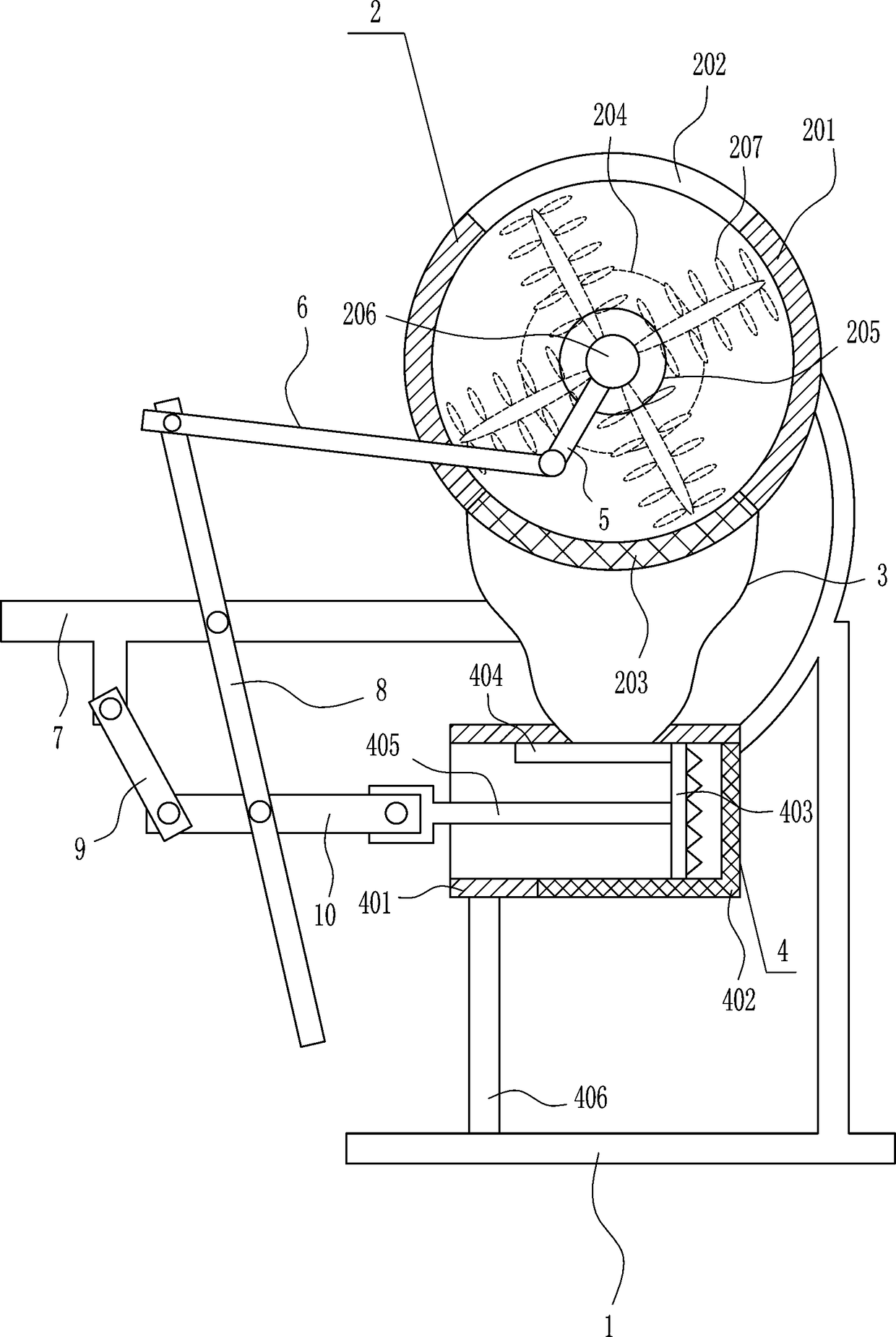

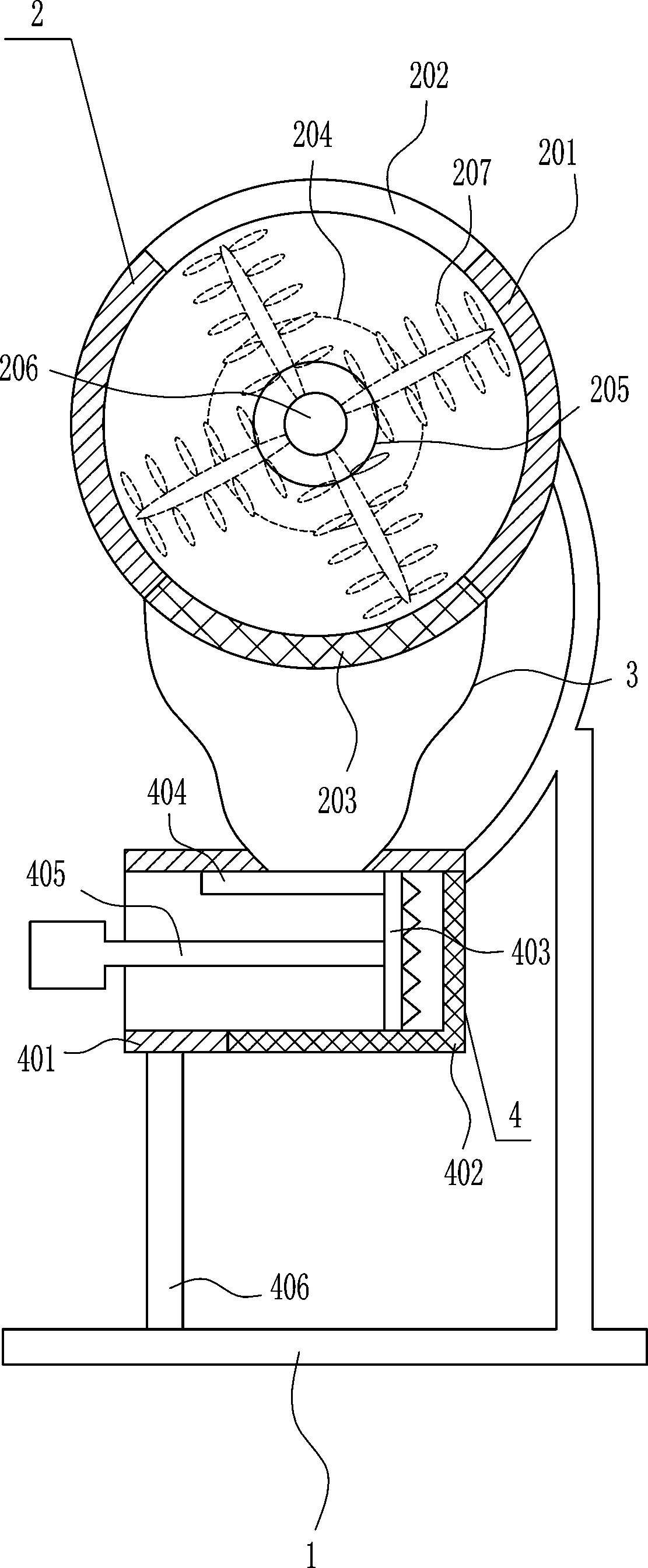

[0032] A kind of caking fertilizer deblocking equipment for garden fertilization, such as Figure 1-5 As shown, it includes a frame 1, a primary crushing mechanism 2, a discharge hopper 3 and a secondary crushing mechanism 4. The top of the right side of the frame 1 is connected to the primary crushing mechanism 2, and the bottom of the primary crushing mechanism 2 is connected to the discharge hopper 3. The left side of the bottom of the frame 1 is connected with a secondary crushing mechanism 4, the top of the secondary crushing mechanism 4 is connected with the bottom of the discharge hopper 3, the secondary crushing mechanism 4 is located directly below the primary crushing mechanism 2, and the right side of the secondary crushing mechanism 4 is connected to the machine. The upper side of frame 1 is connected.

Embodiment 2

[0034] A kind of caking fertilizer deblocking equipment for garden fertilization, such as Figure 1-5 As shown, it includes a frame 1, a primary crushing mechanism 2, a discharge hopper 3 and a secondary crushing mechanism 4. The top of the right side of the frame 1 is connected to the primary crushing mechanism 2, and the bottom of the primary crushing mechanism 2 is connected to the discharge hopper 3. The left side of the bottom of the frame 1 is connected with a secondary crushing mechanism 4, the top of the secondary crushing mechanism 4 is connected with the bottom of the discharge hopper 3, the secondary crushing mechanism 4 is located directly below the primary crushing mechanism 2, and the right side of the secondary crushing mechanism 4 is connected to the machine. The upper side of frame 1 is connected.

[0035] The primary crushing mechanism 2 includes a fixed bucket 201, a first filter screen 203, a motor 204, a bearing seat 205, a rotating rod 206 and a crushing ...

Embodiment 3

[0037] A kind of caking fertilizer deblocking equipment for garden fertilization, such as Figure 1-5 As shown, it includes a frame 1, a primary crushing mechanism 2, a discharge hopper 3 and a secondary crushing mechanism 4. The top of the right side of the frame 1 is connected to the primary crushing mechanism 2, and the bottom of the primary crushing mechanism 2 is connected to the discharge hopper 3. The left side of the bottom of the frame 1 is connected with a secondary crushing mechanism 4, the top of the secondary crushing mechanism 4 is connected with the bottom of the discharge hopper 3, the secondary crushing mechanism 4 is located directly below the primary crushing mechanism 2, and the right side of the secondary crushing mechanism 4 is connected to the machine. The upper side of frame 1 is connected.

[0038] The primary crushing mechanism 2 includes a fixed bucket 201, a first filter screen 203, a motor 204, a bearing seat 205, a rotating rod 206 and a crushing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com