Variable-width roller bending forming material inlet method and variable-width roller bending forming material inlet device

A technology with variable width, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of not being able to adapt to the needs, and achieve the effect of convenient operation, large adaptability, and expanded processing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

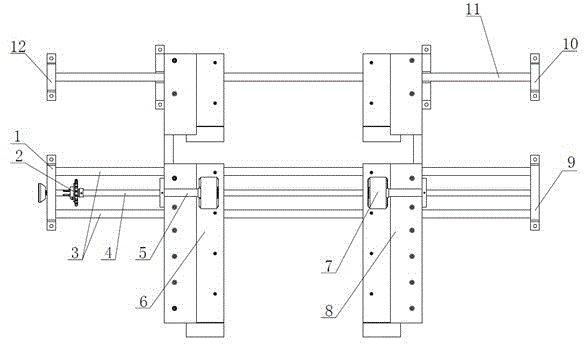

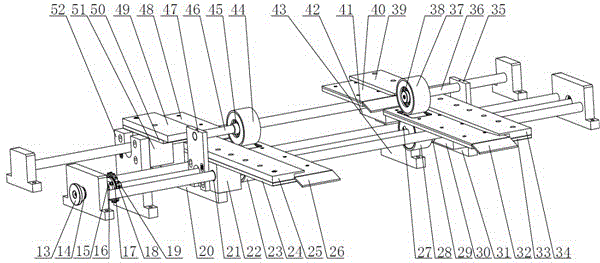

Examples

Embodiment 1

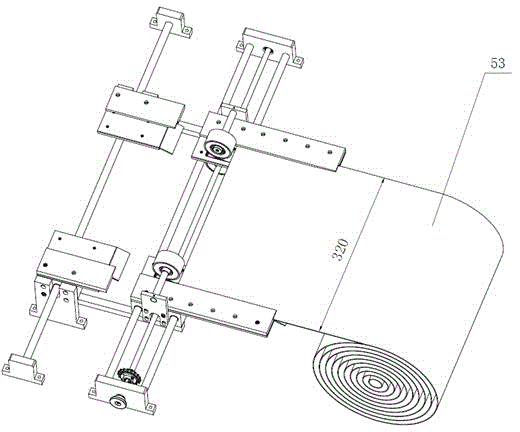

[0026] The variable width roll forming feeding device is adopted, and the size of the imported sheet is as follows image 3 As shown, the width is 320mm. First, adjust the sliding end of the feeding mechanism so that the width between it and the fixed end of the feeding mechanism is 320mm. Then push the handle (13) inward to rotate the power transmission shaft (4) to drive the feeding The roller rotates, and the front end of the sheet is put into the front end of the feed roller, and the sheet will be introduced as the feed roller rotates, thereby realizing the feeding of the sheet.

[0027] To sum up, the variable-width roll forming feeding device of the present invention can realize The width of the feeding device is variable. At the same time, the invention is equipped with a clutch device, which can control the operation and stop of the leading roller at any time, so as to ensure that the feeding and stop of the sheet material can be controlled at any time. The invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com