Optical fiber laser cutting head for laser cutting system

A laser cutting and fiber laser technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of short service life of the laser head protection mirror, disorder of the internal transmission direction of the air flow, reducing the effect of auxiliary laser cutting, etc. Save workload, improve cutting quality and efficiency, stable center position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with specific drawings and embodiments.

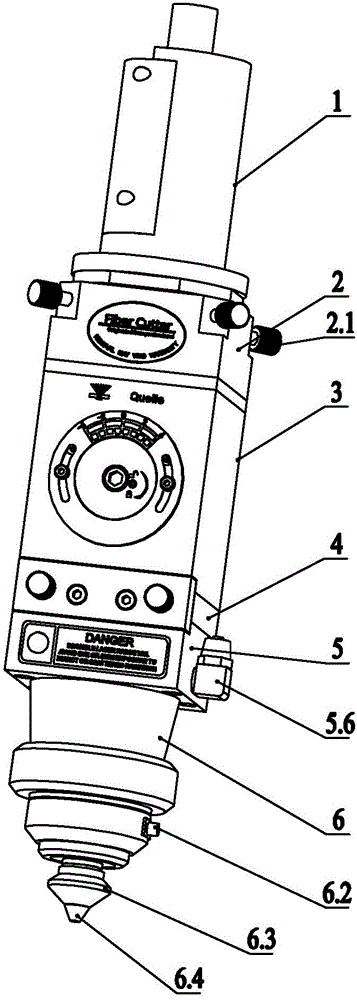

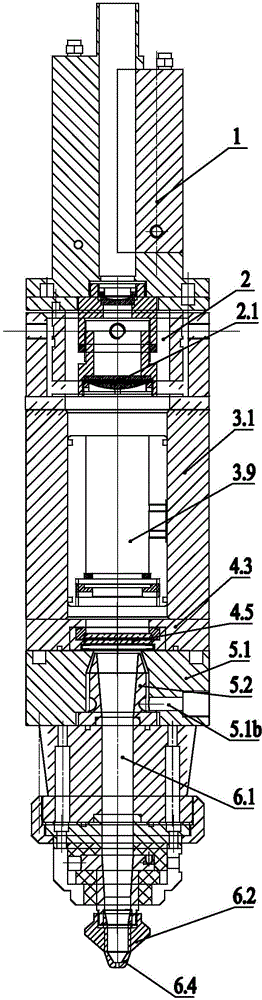

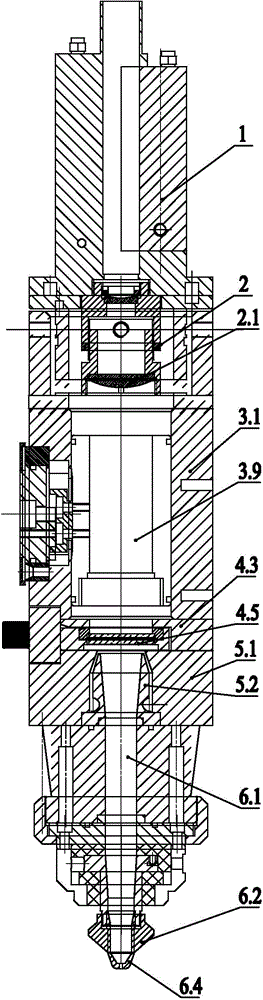

[0032] As shown in the figure: the fiber laser cutting head for the laser cutting system in the embodiment is mainly composed of an optical fiber connector 1, a horizontal adjustment device 2, a focusing device 3, a protective mirror device 4, and an air guiding device connected coaxially from top to bottom. The device 5 and the cutting head 6 are composed of several parts.

[0033] like Figure 1~4As shown in the figure, the focusing device 3 in the embodiment is mainly composed of a focus adjusting seat 3.1, a focusing knob seat 3.2, a focusing dial 3.3, a focusing knob 3.4, a focusing barrel connecting plate 3.5, a focusing bolt 3.6, a locking The screw 3.7, the first O-ring 3.8, the focusing tube 3.9, the second O-ring 3.10 and the focusing lens 3.11 are composed.

[0034] The focus adjusting seat 3.1 is provided with a focusing tube slideway 3.1a, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com