Excircle grinding machine for forged bars

A bar and grinding technology, applied in the direction of grinding machines, machine tools designed for grinding the rotating surface of workpieces, manufacturing tools, etc., can solve the problems of surface cracks, non-standard surface shape tolerance, small grinding range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

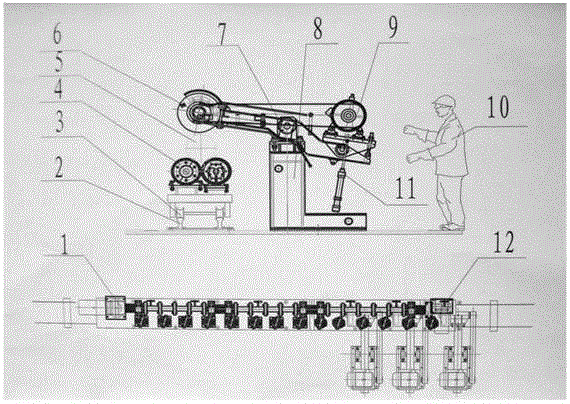

[0011] Example of implementation of the present invention: as shown in the figure, the bars 5 of various specifications after forging are hoisted by a crane and placed on the two rows of rotating rollers 4, and the main shaft rotating motor 1 is started to drive the rotating rollers 4 to rotate. Due to the frictional force generated by the contact between the bar 5 and the rotating roller 4, the bar 5 is rotated counterclockwise. At this time, the operator 10 starts to start the main machine for grinding, so that the grinding head 6 is driven by the grinding head motor 9 connected by the belt to start rotating. Waiting for the grinding process, at this time, the operator 10 uses the principle that the grinding head 6 can rotate around the grinding head rotation axis 7, operates the machine to press the grinding head to the top of the processed bar 5, and at the same time adjusts the balance cylinder 11 The mechanism is to make the grinding head 6 increase or decrease the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com