Plastic pipe interface device

A technology of interface equipment and plastic pipes, which is applied in the direction of mechanical equipment, pipeline connection layout, pipes/pipe joints/fittings, etc., can solve the problems of plastic pipe joint failure, joint falling off, and small axial pressure resistance and impact force at the butt joint, etc. Achieve the effects of easy use and maintenance, guaranteed performance, and firm interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. However, the uses and purposes of these exemplary embodiments are only used to illustrate the present invention, and do not constitute any form of limitation to the actual protection scope of the present invention, nor limit the protection scope of the present invention thereto.

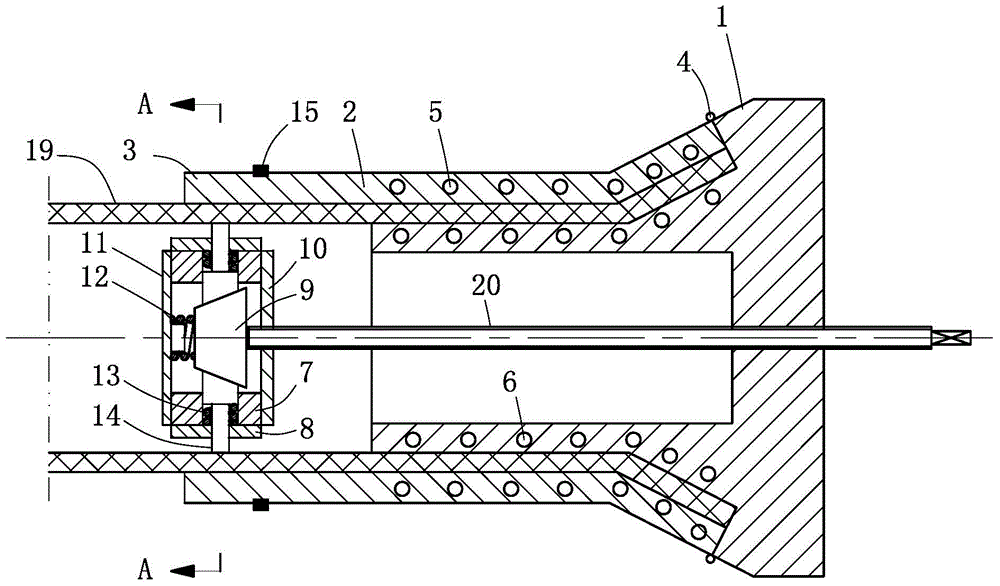

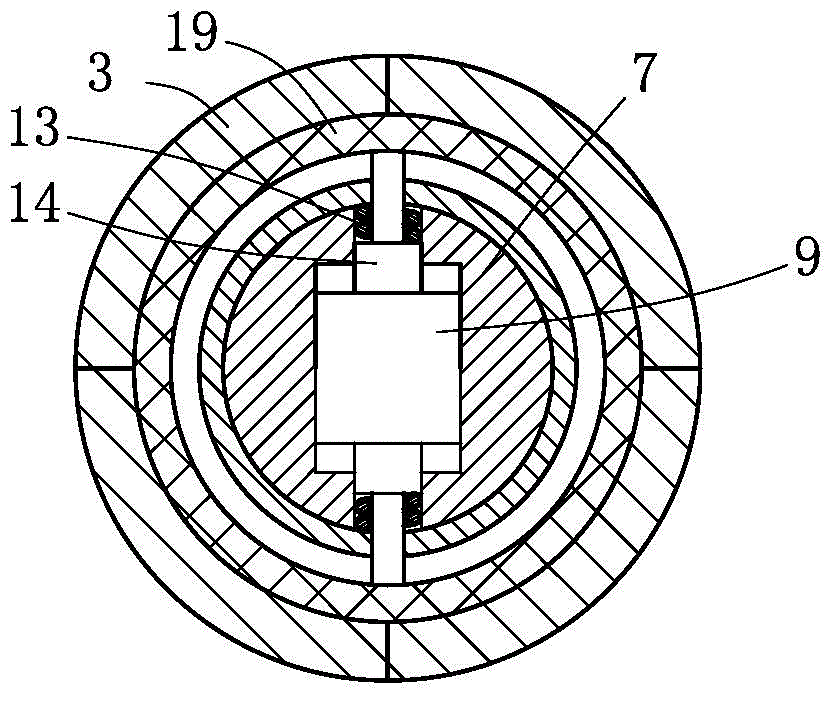

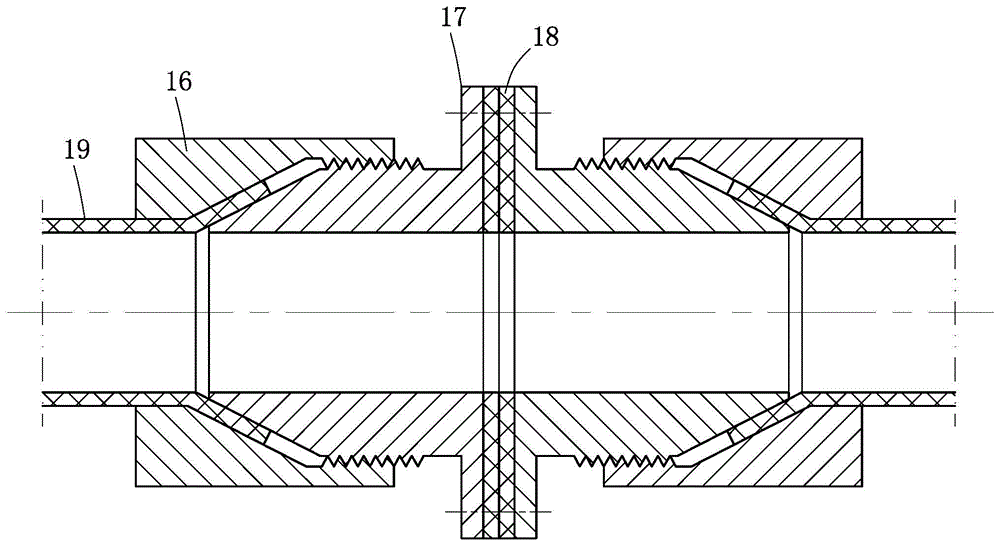

[0027] Such as figure 1 , figure 2 and image 3 Commonly shown in, the present invention provides a plastic pipe interface device, the plastic pipe interface equipment mainly includes a flaring device for flaring the end of the plastic pipe 19 into a bell mouth and for tightening and connecting the bell mouth The connecting device together, the flaring device includes a flared inner body 1 and a flared outer body connected together, a horn-shaped cavity is formed between the flared inner body 1 and the flared outer body, and the flared cavity is surrounded by a flared cavity....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com