High-strength aramid fiber printing conduction band of printing machine

A high-strength, printing machine technology, applied in the direction of lamination, layered products, synthetic resin layered products, etc., can solve the problems of low strength, layering, uneven conduction belt, etc., and achieve high temperature resistance, high density, The effect of strong interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

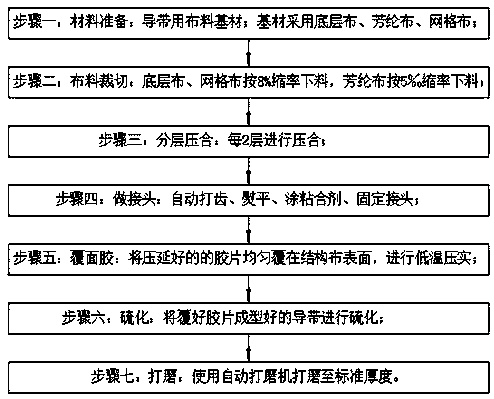

[0025] see figure 1 , the present invention provides a technical solution: a printing machine high-strength aramid printing guide belt, the preparation method is as follows:

[0026] Step 1: Material preparation: fabric base material for guide belt; base material is base cloth, aramid cloth, mesh cloth; 1 layer of base cloth, 1 layer of aramid cloth, 2 layers of grid cloth, aramid cloth as printing guide belt tension layer;

[0027] Step 2: Cloth cutting: the base cloth and grid cloth are cut at a shrinkage rate of 8%, and the aramid cloth is cut at a shrinkage rate of 5‰;

[0028] Step 3: Layered lamination: Under the pressure of 13MPa and the temperature of 110°C, lamination is carried out every 2 layers, and the interlayers are bonded without glue, and the conduction tape is not easy to delaminate;

[0029] Step 4: Make joints: automatic punching, ironing, applying adhesive, and fixing the joints; the base layer needs to be leveled before applying the adhesive, and the co...

Embodiment 2

[0035] see figure 1 , the present invention provides a technical solution: a printing machine high-strength aramid printing guide belt, the preparation method is as follows:

[0036] Step 1: Material preparation: fabric base material for guide belt; base material is base cloth, aramid cloth, mesh cloth; 1 layer of base cloth, 1 layer of aramid cloth, 2 layers of grid cloth, aramid cloth as printing guide belt tension layer;

[0037] Step 2: Cloth cutting: the base cloth and grid cloth are cut at a shrinkage rate of 8%, and the aramid cloth is cut at a shrinkage rate of 5‰;

[0038] Step 3: Layered lamination: Under the pressure of 15MPa and the temperature of 120°C, lamination is carried out for every 2 layers. The interlayers are bonded without glue, and the conduction tape is not easy to be delaminated;

[0039] Step 4: Make joints: automatic punching, ironing, applying adhesive, and fixing the joints; the base layer needs to be leveled before applying the adhesive. solid...

Embodiment 3

[0045] see figure 1 , the present invention provides a technical solution: a printing machine high-strength aramid printing guide belt, the preparation method is as follows:

[0046] Step 1: Material preparation: fabric base material for guide belt; base material is base cloth, aramid cloth, mesh cloth; 1 layer of base cloth, 1 layer of aramid cloth, 2 layers of grid cloth, aramid cloth as printing guide belt tension layer;

[0047] Step 2: Cloth cutting: the base cloth and grid cloth are cut at a shrinkage rate of 8%, and the aramid cloth is cut at a shrinkage rate of 5‰;

[0048] Step 3: Layered lamination: Under the pressure of 17MPa and the temperature of 130°C, lamination is carried out for every 2 layers. The bonding between the layers does not need to be bonded with glue, and the conduction tape is not easy to delaminate;

[0049] Step 4: Make joints: automatic punching, ironing, applying adhesive, and fixing the joints; the base layer needs to be leveled before apply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com