A connection device for a cable interface of a servo motor

A connection device and servo motor technology, applied in the field of servo motors, can solve problems such as decreased interface connection tightness, interface component damage, and increased time cost, achieving the effects of stable interface, stable structure, and reduced installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

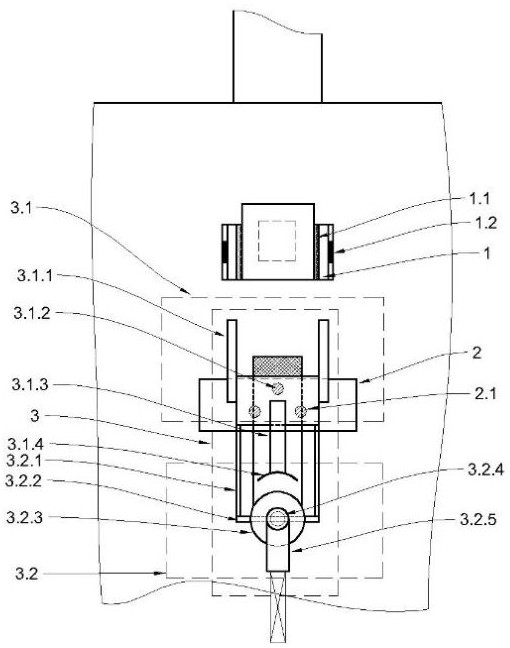

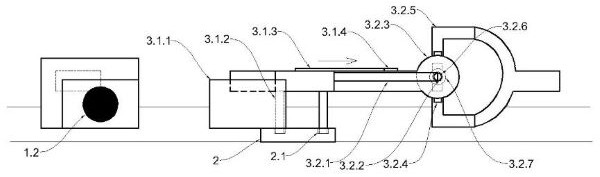

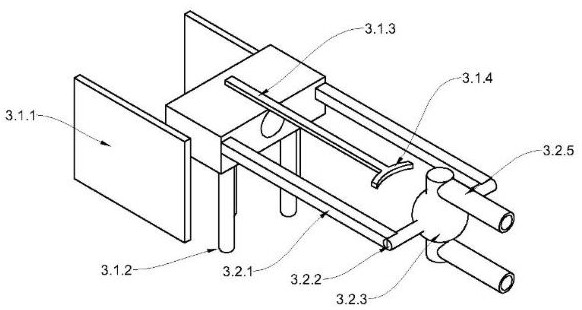

[0025] The structure of the servo motor cable interface connection device according to the present invention will now be fully described with reference to specific embodiments, so that those skilled in the art can fully understand and implement.

[0026] like Figure 1-Figure 5 Shown: a connecting device for a cable interface of a servo motor. The connecting device includes a cable interface and a cable. The cable interface is located at the front of the side wall of the casing. The orientation of the cable interface is parallel to the casing of the casing. There are two parallel sockets 1 on the left and right sides of the cable interface. The inner plate of the socket 1 is a ceramic plate 1.1, and a permanent magnet suction cup 1.2 is embedded in the side wall of the outer plate. The bracket 2 slides the shell to the cable interface, the bracket 2 is provided with positioning grooves 2.1, the positioning grooves 2.1 are three, and the plane distribution is triangular; The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com