Thin-film pressure sensor and manufacturing method

A thin-film pressure sensor technology, applied in the field of sensors, can solve the problems of thin-film pressure sensor application quality limitations, reduced sensor sensitivity performance, and weak wire connection, etc., to achieve the effects of ensuring pressure-sensitive performance, easy manufacturing method, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

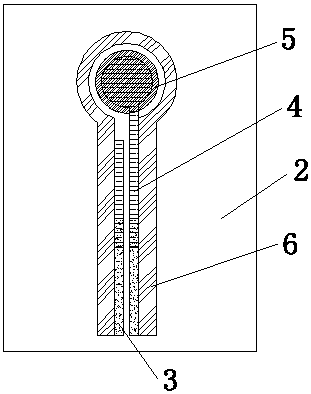

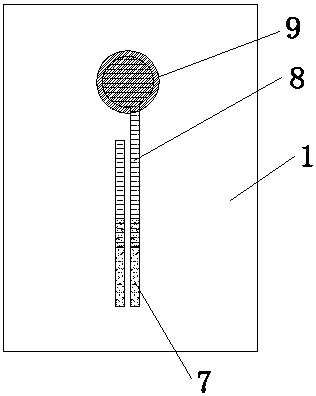

[0011] Example: Combine figure 1 , figure 2 An embodiment of the thin film pressure sensor of the present invention will be described. Firstly, the drawing design of the thin-film sensor is carried out, including the sensor shape, the design of the interface electrode on the lower substrate film, the printed electrode, the sensitive material layer, the adhesive material layer, and the touch electrode, printed electrode, and sensitive material layer on the upper substrate film. Drawings of the various parts of the sensor. According to the design drawing of the sensor, use the 0.1mm thick flexible copper clad film to cut two pieces of the same size copper clad film, respectively, as the upper and lower film substrates (1) and (2); use the etching technology in the flexible circuit board manufacturing process , the touch electrode (7) and the interface electrode (3) are etched on the upper and lower film substrates (1) and (2); the upper and lower film substrates (1) and (2) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com