Cable interface for servo motor and cable

A technology of servo motors and cables, applied in the field of servo motors, can solve the problems of decreased interface connection tightness, damage to interface components, affecting normal use, etc., and achieves the effects of stable interface, stable structure, and reduced installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The structure of the servo motor cable interface and the cable according to the present invention will be fully described in conjunction with specific embodiments, so that those skilled in the art can fully understand and implement it.

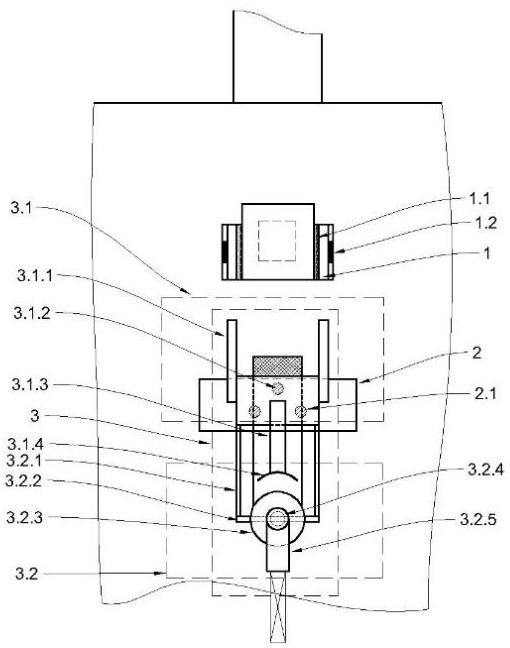

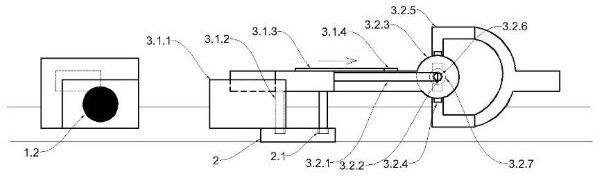

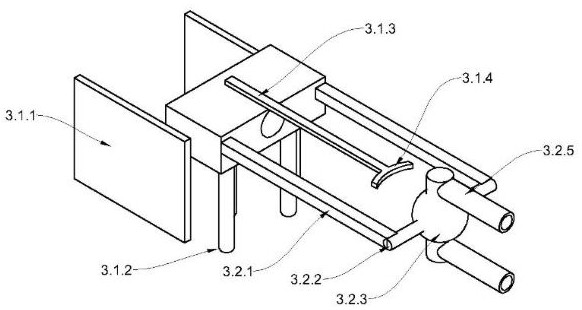

[0026] Such as Figure 1-Figure 5 Shown: a cable interface and cables for servo motors, the cable interface is located at the front of the side wall of the casing, the cable interface is oriented parallel to the casing shell, and there are two parallel sockets on the left and right sides of the cable interface 1. The inner plate of the socket 1 is a ceramic plate 1.1, and the side wall of the outer plate is embedded with a permanent magnetic sucker 1.2; the casing is provided with a bracket 2 that slides along the shell to the cable interface at a certain position away from the cable interface , there are positioning grooves 2.1 on the bracket 2, three positioning grooves 2.1, and the plane distribution is triangular; the cable is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com