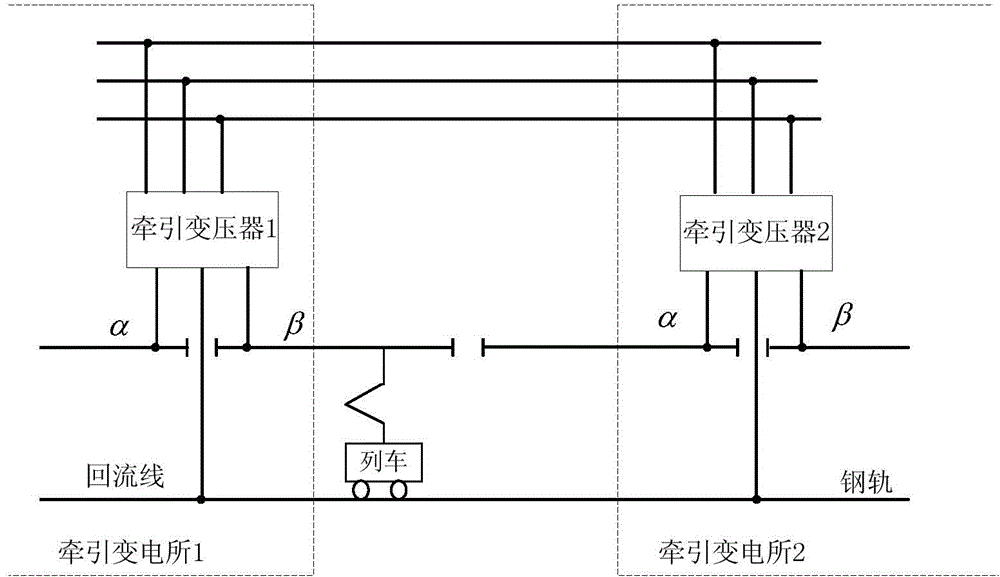

Co-phase power supply device and traction power supply system

A technology of traction power supply system and in-phase power supply, which is applied in the direction of output power conversion devices, electrical components, power lines, etc., can solve the problems of passenger comfort, train running speed, transformer loss, etc., and achieve comprehensive management and capacity reduction. Maximum utilization of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples, so as to fully understand and implement the process of how to apply technical means to solve technical problems and achieve technical effects in the present invention. It should be noted that, as long as there is no conflict, each embodiment and the features of each embodiment in the present invention can be combined with each other, and the formed technical solutions are all within the protection scope of the present invention.

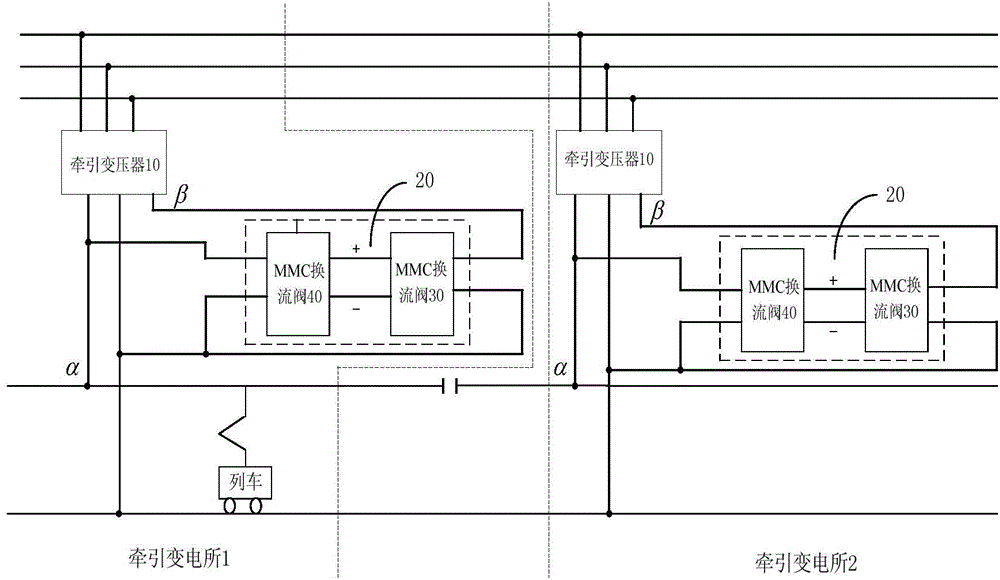

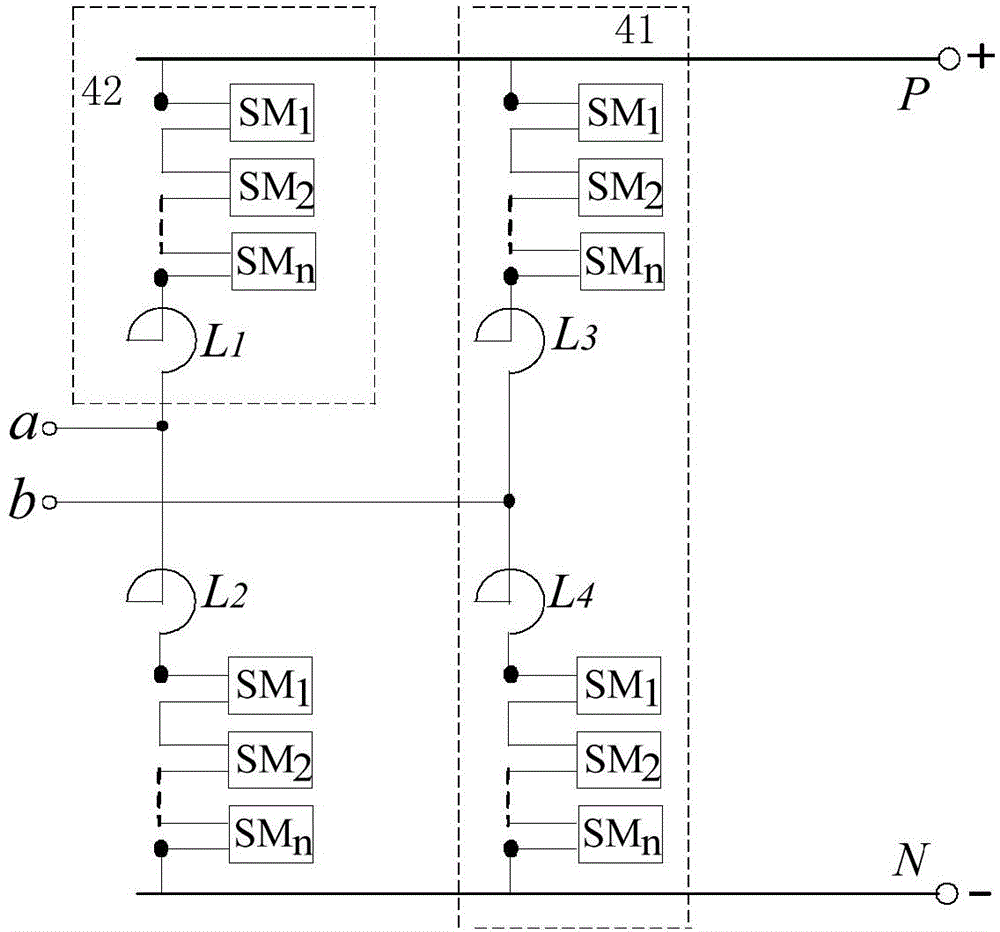

[0036] Such as figure 2 Shown is the composition structure and connection diagram of the in-phase power supply device and the traction power supply system provided by the present invention. The power system provides a 110kV / 220kV voltage power supply, which is converted into a 27.5kV / 55kV power supply by the traction transformer 10. After being transformed by the traction power supply system 20, the output Single-phase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com