Dual-motor BBW (brake-by-wire) system with multiple working modes and voltage regulation modes

A voltage regulation method and brake-by-wire technology, which is applied in the directions of brakes, brake transmissions, transportation and packaging, etc. It can solve the problem that the dynamic performance of the motor cannot meet the multi-channel multiplexing method, cannot meet the pressure regulation target, and fail the backup mechanism. Complex structure and other problems, to achieve the effect of improving failure protection capability, high reliability, and avoiding potential risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

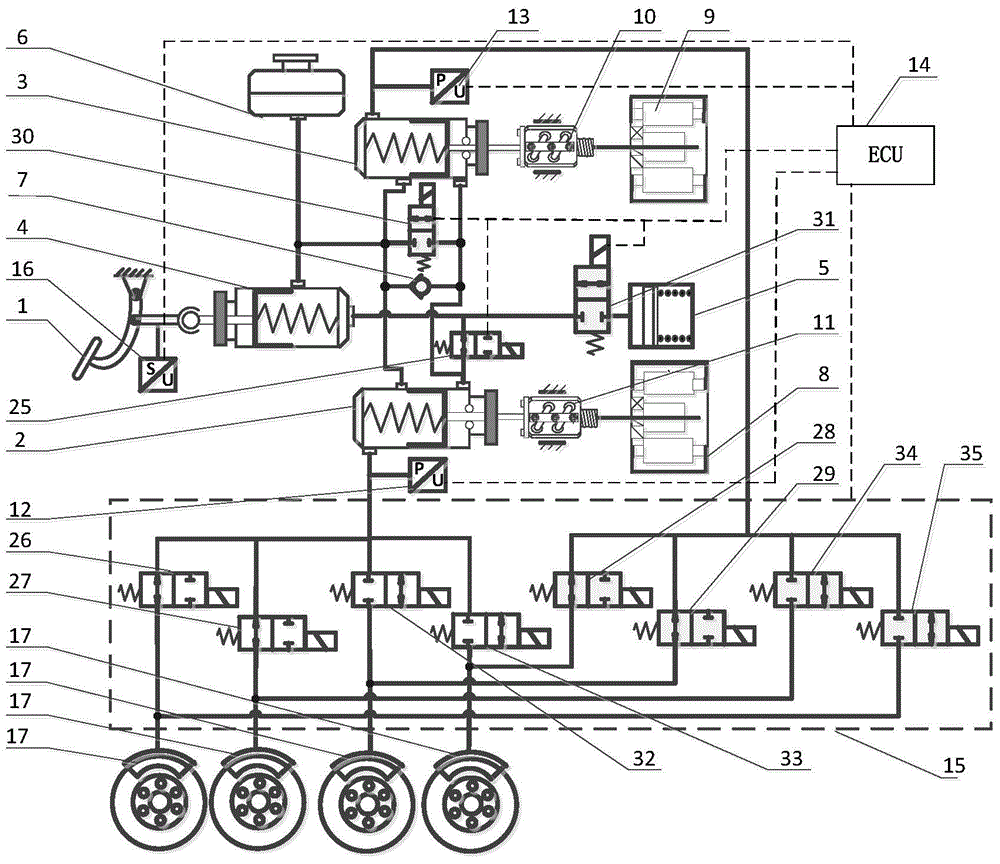

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

[0037] A dual-motor brake-by-wire system with multiple working modes and pressure regulation, including a brake pedal 1, a first master cylinder 2, a second master cylinder 3, a human cylinder 4, a pedal stroke simulator 5, and a fluid storage cup 6. Check valve 7, first motor 8, second motor 9, first ball screw pair 10, second ball screw pair 11, first master cylinder pressure sensor 12, second master cylinder pressure sensor 13, electronic Control unit 14, hydraulic control unit 15, brake pedal stroke sensor 16, four wheel cylinders 17, and 2 / 2 normally open solenoid valve A25, 2 / 2 normally closed solenoid valve A30, 2 / 2 normally closed solenoid valve B31.

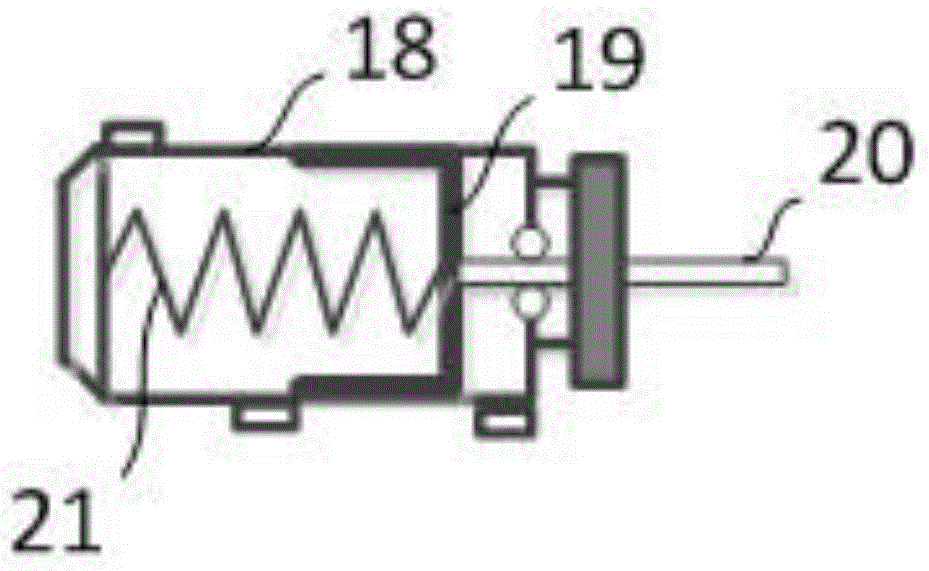

[0038] Wherein, the first master cylinder 2 , the second master cylinder 3 and the manpower cylinder 4 are all single-piston cylinders, including a cylinder body 18 , a piston 19 , a piston rod 20 and a piston re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com