A vehicle integrated electro-hydraulic braking system

A brake system, integrated electro-hydraulic technology, applied in the direction of brakes, vehicle components, brake transmissions, etc., can solve the problems of reduced reliability, high cost, complex structure, etc., and achieve adjustable brake pedal feel and pressure regulation The effect of high precision and small pressure fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with accompanying drawing.

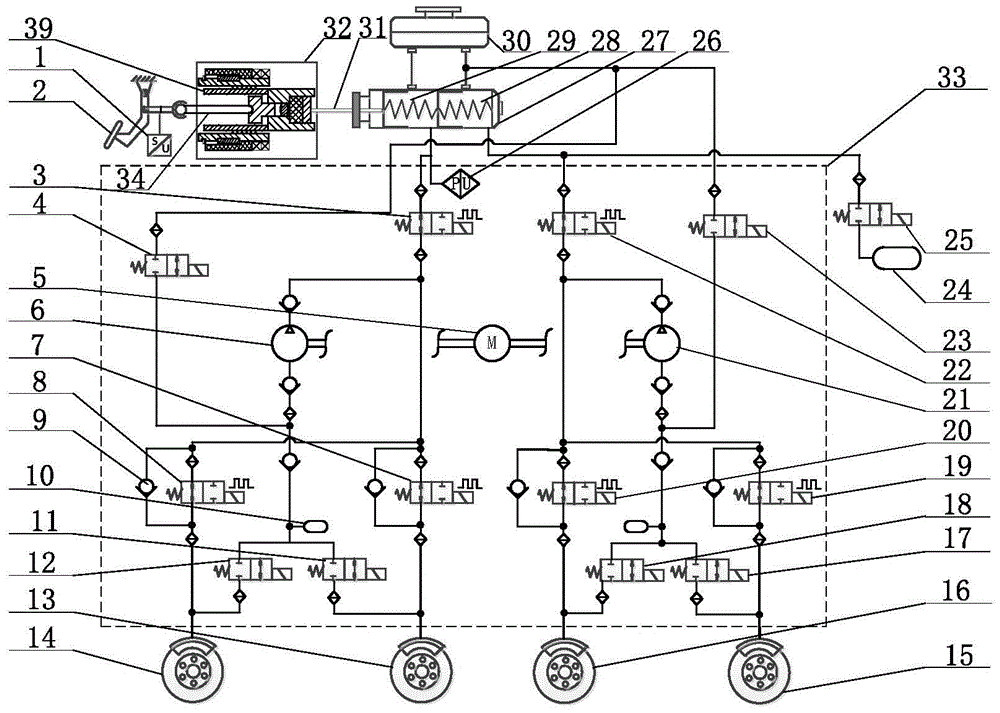

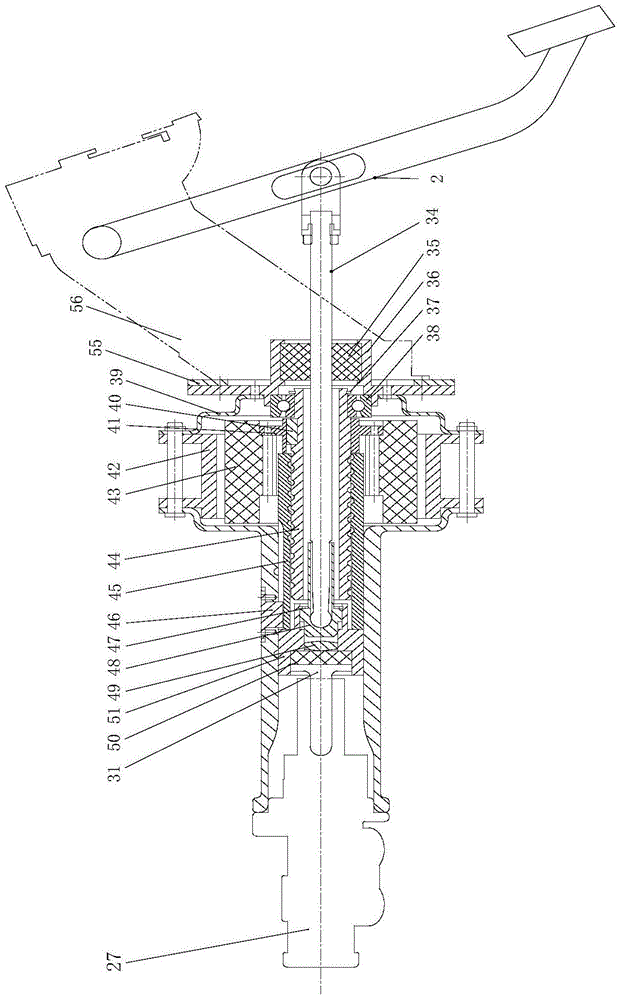

[0043] The vehicle integrated electro-hydraulic brake system of the present invention includes an electric brake booster device 32, a brake pedal 2, a pedal stroke simulator 24, a hydraulic control unit 33 and sensor components.

[0044] Described brake pedal 2 links to each other with pedal bracket 56 through support pin, and pedal bracket 56 is fixedly connected with the rear end face of firewall 55 on the automobile. Brake pedal 2 links to each other with the input end of brake push rod 34 through spherical seat, to prevent the impact of brake pedal 2 push rod vertical direction movement on brake push rod 34; The piston push rods 31 of the dual-chamber brake master cylinders are connected to each other. During the braking process, the brake pedal 2 is depressed by manpower, so that the brake push rod 34 moves forward, and then the piston push rod 31 of the brake master ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com