Servo control and drive lift-and-turn compound motion mechanism

A composite motion and servo control technology, applied in the direction of lifting devices, etc., can solve the problems of high relative failure rate and complex structure, and achieve the effects of strong reliability, simplified mechanical transmission structure, and avoidance of pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

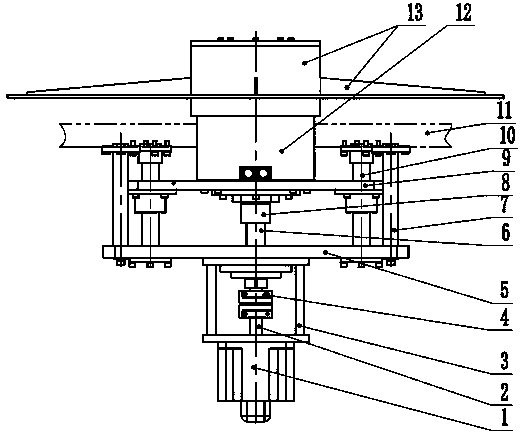

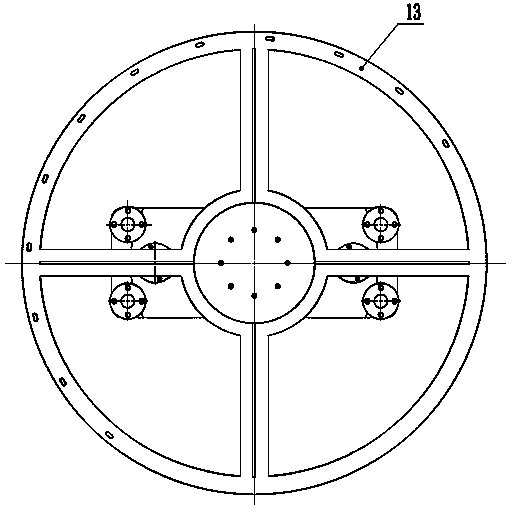

[0012] see figure 1 —— figure 2 , a lifting and turning compound motion mechanism driven by servo control, including a table top 11 with a hole in the center, a support frame is provided below the table top 11, and the support frame includes an upper support frame 7 fixed on the table top 11 and The lower support frame 3 connected to the bottom plate 5 of the upper support frame 7 is fixed with a servo motor 1 on the lower support frame 3, and the rotating shaft 2 of the servo motor 1 is connected with the ball screw 6 through the coupling 4, and the ball screw 6 is connected with the ball screw 6. The ball screw lifting seat 8 is connected, the ball screw lifting seat 8 is connected with the lifting platform 9, and the lifting platform 9 is provided with a lifting guide column 10 on the left and right, and the upper end of the lifting guide column 10 is fixed on the table panel 11, and the lower end is fixed on the support frame 7. On the bottom plate 5, the left and right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com