Glass object

An article and glass technology, applied in the field of glass articles, can solve the problems of unknown changes in chemical strengthening suitability, loss of chemical durability, and excessive alkali.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

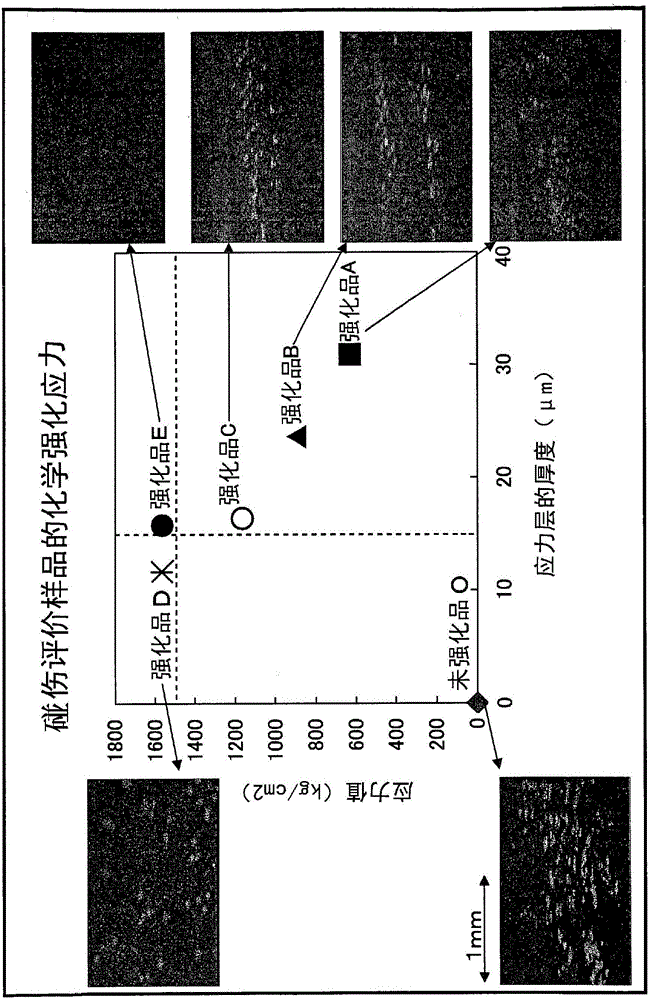

[0101] The composition of Example 1 satisfies the predetermined legal crystal glass conditions in terms of glass composition, refractive index, and density similarly to the composition of the known potassium-zinc crystal glass suitable for chemical strengthening (Comparative Example 1), and its alkali elution The amount is small, so it shows excellent chemical resistance. The composition of the crystal glass of the present invention also has chemical strengthening suitability effective in improving the practical strength of tableware, which will be described in detail below.

[0102] [Table 1]

[0103]

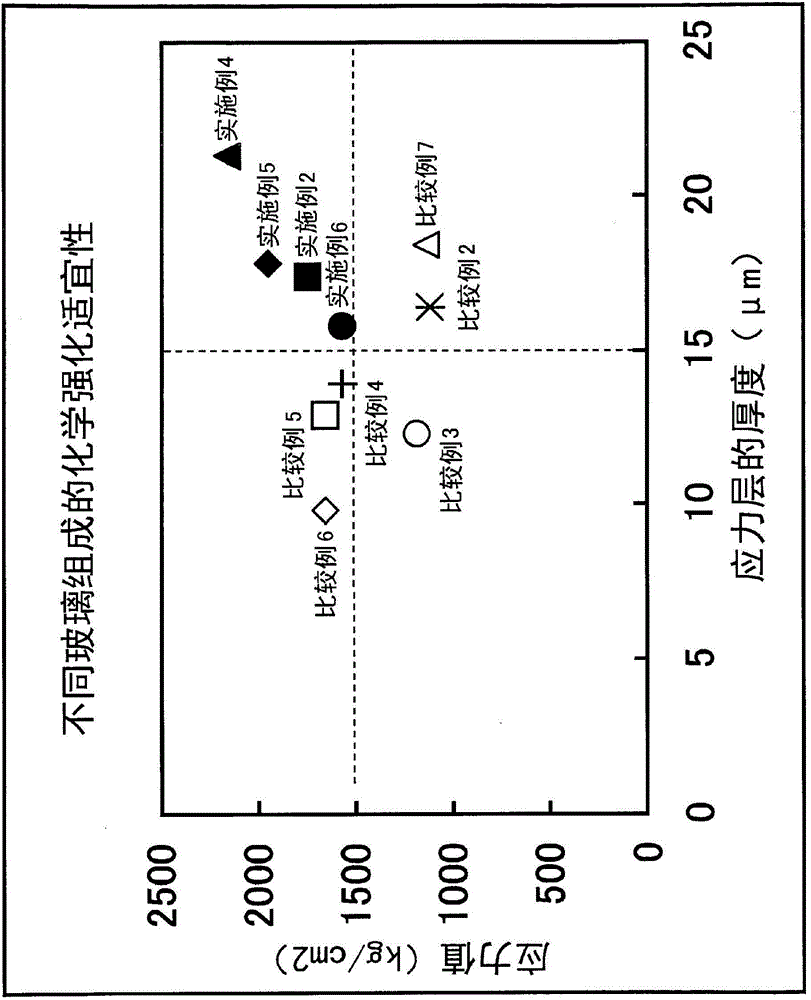

[0104] Table 2 shows that in the present invention, substituting a part of ZnO in the known composition with specific compositional ratios of three kinds of alkaline earth oxides (MgO, CaO, and SrO) contributes to the maintenance of chemical strengthening. Ion exchange facilitates function.

[0105] In Example 2 and Examples 4 to 6, after surface coating with potassium aq...

Embodiment 6

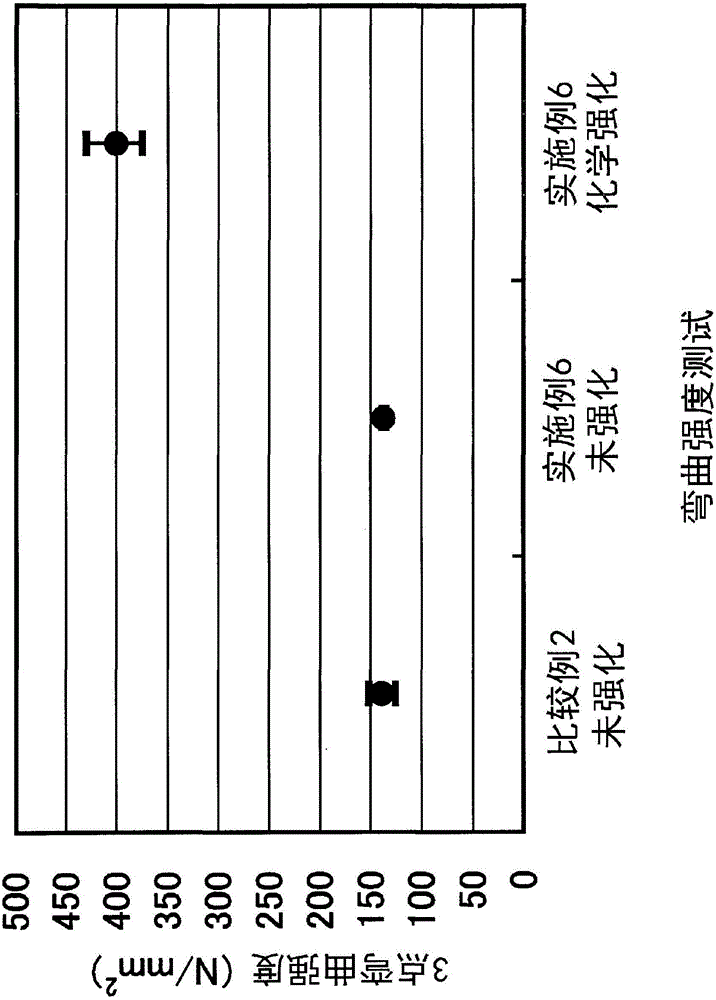

[0118] The Vickers hardness of the glass of Example 6 was: 561Hv before chemical strengthening, and 587Hv after chemical strengthening.

[0119] After soaking the surface of the glass sample composed of the embodiment of the present invention and the surface of the glass sample composed of the comparative example with a potassium salt solution, the temperature range of 420°C, 440°C, 460°C, and 480°C within the temperature range suitable for ion exchange Carry out the ion exchange of 90 minutes, measure the thickness and the stress value of the chemical strengthening stress that is given, the comparison result of the same kind of the best example is shown in Table 2 and figure 2 . It is given in the embodiment that it can impart a thickness greater than 15 μm necessary for scratch resistance, and greater than 1500 kg / cm 2 The ion exchange conditions of the stress values, while the comparative examples do not show better than them.

[0120] The high bending strength of the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com