Linen shell fabric and production method

A production method and fabric technology, applied in textiles and papermaking, fiber treatment, plant fibers, etc., can solve problems such as poor wearing comfort, sweat can not be discharged, and heatstroke is easy to cause, so as to achieve wide application range, reduce production costs, and produce The method is simple and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

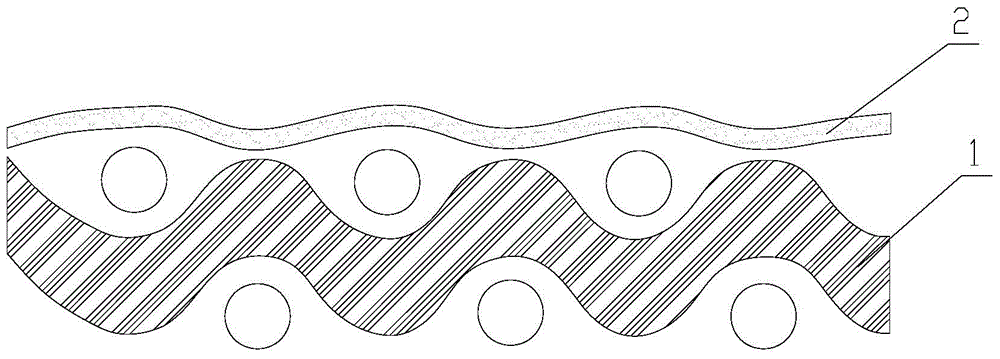

[0038] figure 1 It is the structural representation of the hemp fabric of the present embodiment. As shown in the figure, the linen fabric of this embodiment includes a linen base layer 1 and a PVDF layer 2 coated on the linen base layer 1 . Wherein, the linen base layer 1 is pure linen fabric.

[0039] Since the PVDF layer is only formed on the surface of the fabric and is an extremely thin layer, the setting of the PVDF layer will not destroy the antibacterial, moisture-wicking, cool and comfortable functions of the linen fabric itself and make the linen fabric have good air permeability; PVDF material has poor hydrophilicity, has good chemical corrosion resistance, high temperature resistance, oxidation resistance, abrasion resistance, flexibility, impact resistance, and can effectively resist ultraviolet rays. It is suitable for making raincoats, sun protection clothing, outdoor clothing, etc.

Embodiment 2

[0041] The basic structure of the linen fabric in this embodiment is the same as that in the first embodiment, including a linen base layer and a PVDF layer coated on the linen base layer. The difference is that the material of the linen base layer in this embodiment is not limited, and linen fabrics such as pure linen fabrics, linen-like fabrics, cotton-linen fabrics, and silk-linen fabrics are all available; the PVDF layer is not limited to one layer, and the layer can be determined according to actual needs. number; in order to meet some special requirements, other coatings can be set on the outside of the PVDF layer or between the linen base layer and the PVDF layer.

Embodiment 3

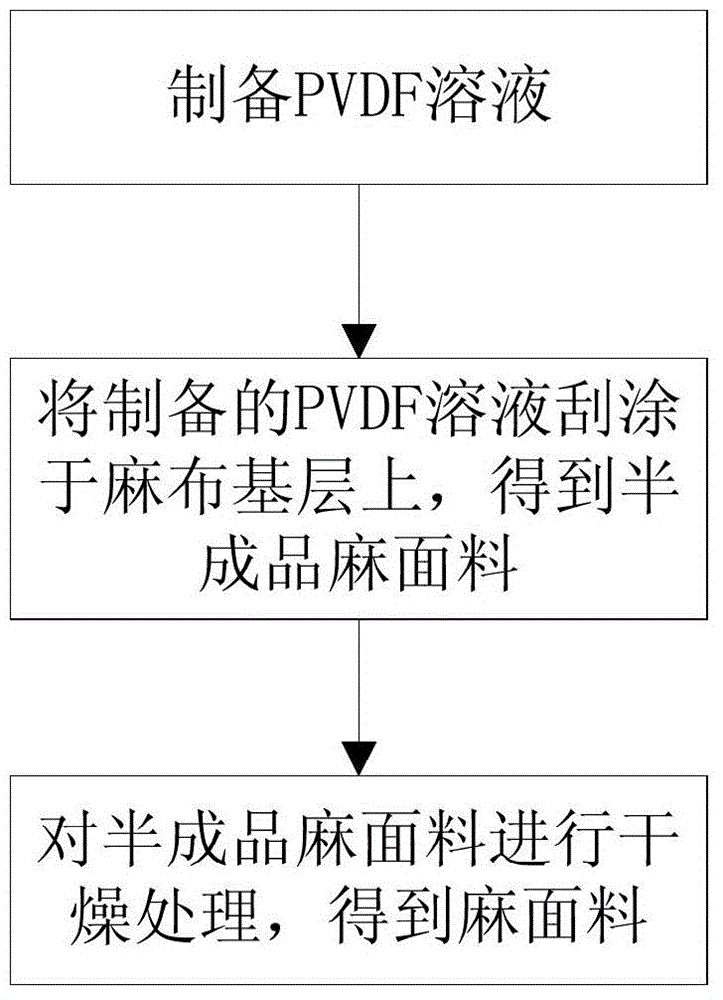

[0043] The present embodiment is the method for making hemp fabric as described in embodiment one or two, such as figure 2 As shown, the preparation method of the hemp fabric at least includes:

[0044] Step A, prepare PVDF solution;

[0045] Step B, scraping the PVDF solution prepared in step A on the linen base layer to obtain a semi-finished linen fabric;

[0046] Step C, drying the semi-finished linen fabric obtained in step B to obtain the above-mentioned linen fabric.

[0047] In step A, the specific preparation process of the PVDF solution is to dissolve the PVDF powder in an oily solvent to prepare a PVDF solution with a mass fraction of 5%-10%, and stir the PVDF solution at a constant temperature of 50-70°C. Stir for 1-2 hours until there is no powdery object in the solution, then let the solution stand for defoaming, and the required PVDF solution can be obtained in about 30 minutes. The oily solvent is not limited, and any oily solvent with a smaller molecular w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com