Environment-friendly high-barrier coating composition for aluminum-free backing paper and preparation method thereof

A high-barrier, environmentally friendly technology, used in paper coatings, papermaking, coatings, etc., can solve the problems of high power consumption, reduced barrier properties, and high viscosity of coatings, and achieves simple application equipment, stable barrier properties, and high performance. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

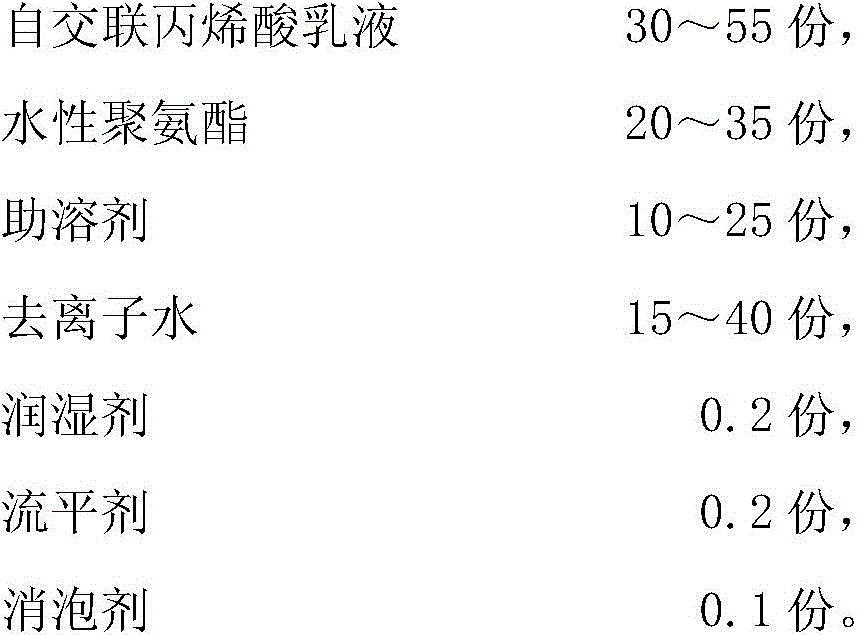

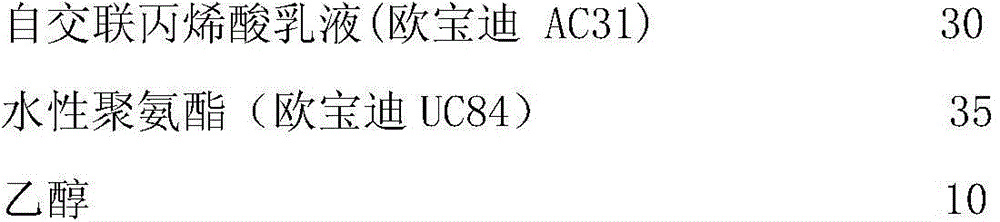

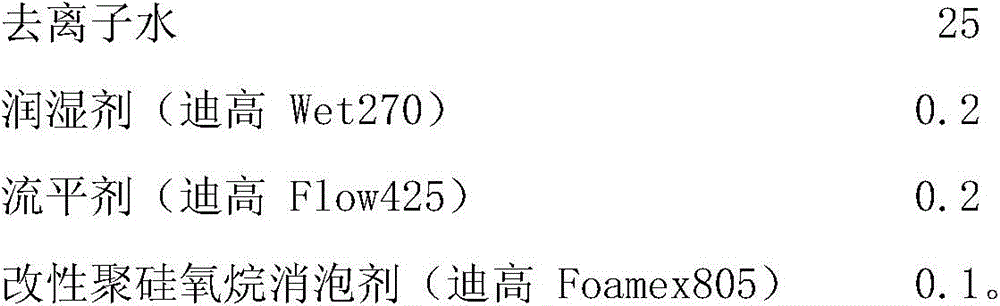

[0029] The environment-friendly high-barrier coating composition for aluminum-free backing paper of this embodiment includes the following components and contents (parts by weight):

[0030]

[0031]

[0032] Concrete preparation comprises the following steps:

[0033] (1) prepare materials according to the above components and content (parts by weight);

[0034] (2) Put the self-crosslinking acrylic emulsion and water-based polyurethane into the reaction kettle, and stir evenly at a low speed (300-500rpm);

[0035] (3) After mixing the co-solvent ethanol and deionized water evenly, add it into the reaction kettle while stirring, and stir at 300-500rpm for 5-10min;

[0036] (4) Add wetting agent and leveling agent to the reaction kettle in sequence, and stir at a medium speed (700-800rpm) for 10-20 minutes;

[0037] (5) Add modified polysiloxane defoamer to the reaction kettle, stir at high speed (1000-1200rpm) for 30-40 minutes;

[0038] (6) Detect the above steps to...

Embodiment 2

[0040] The environment-friendly high-barrier coating composition for aluminum-free backing paper of this embodiment includes the following components and contents (parts by weight):

[0041]

[0042] Concrete preparation comprises the following steps:

[0043] (1) prepare materials according to the above components and content (parts by weight);

[0044] (2) Put the self-crosslinking acrylic emulsion and water-based polyurethane into the reaction kettle, and stir evenly at a low speed (300-500rpm);

[0045] (3) After mixing the co-solvent isopropanol and deionized water evenly, add it to the reaction kettle while stirring, and stir at 300-500rpm for 5-10min;

[0046] (4) Add wetting agent and leveling agent to the reaction kettle in sequence, and stir at a medium speed (700-800rpm) for 10-20 minutes;

[0047] (5) Add modified silicone defoamer to the reaction kettle, stir at high speed (1000-1200rpm) for 30-40 minutes;

[0048] (6) Detect the above steps to obtain the so...

Embodiment 3

[0050] The environment-friendly high-barrier coating composition for aluminum-free backing paper of this embodiment includes the following components and contents (parts by weight):

[0051]

[0052] Concrete preparation comprises the following steps:

[0053] (1) prepare materials according to the above components and content (parts by weight);

[0054] (2) Put the self-crosslinking acrylic emulsion and water-based polyurethane into the reaction kettle, and stir evenly at a low speed (300-500rpm);

[0055] (3) After mixing the co-solvent propylene glycol ether and deionized water evenly, add it into the reaction kettle while stirring, and stir at 300-500rpm for 5-10min;

[0056] (4) Add wetting agent and leveling agent to the reaction kettle in sequence, and stir at a medium speed (700-800rpm) for 10-20 minutes;

[0057] (5) Add non-ionic surfactant type defoamer to the reaction kettle, stir at high speed (1000-1200rpm) for 30-40 minutes;

[0058] (6) Detect the above ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com