Composite seamless expansion joint for bridge

A seamless expansion and bridge technology, applied in the field of expansion joints, can solve the problems of difficult application, long maintenance time, bridge vibration, etc., and achieve the effect of simple structure and construction, convenient and quick construction, and favorable vibration absorption of bridges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The structure and preparation process of a bridge composite seamless expansion joint provided by the present invention will be further described in detail below in conjunction with the embodiments.

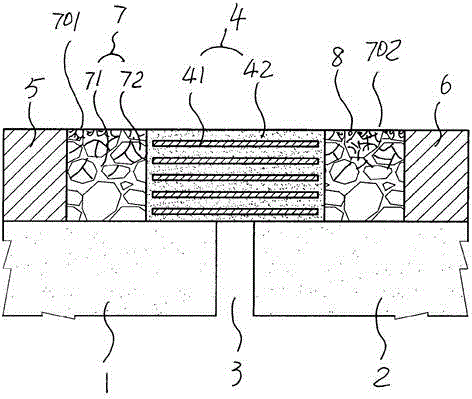

[0023] Such as figure 1 Shown is a structural schematic view of the bridge composite seamless expansion joint provided by the present invention. Among them, the structure of the bridge composite seamless expansion joint consists of a composite member 4 that can be fixed between the gaps 3 between the two adjacent left and right prefabricated parts 1 and 2 that constitute the bridge, and is made of alternately laminated and vulcanized composite members 4 made of multi-layer steel plates 41 and rubber layers 42; The asphalt elastic-plastic body 7 formed by pouring molten asphalt material 71 and gravel 72 between the composite member and the bridge deck pavement layers 5 and 6 on both sides is formed.

[0024] In the structure that constitutes the composite seamless expansion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com