Movable fabricated independent steel box foundation

An independent foundation and prefabricated technology, applied in infrastructure engineering, construction, etc., can solve the problems of time-consuming, labor-intensive, cost-increasing, and time-wasting demolition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

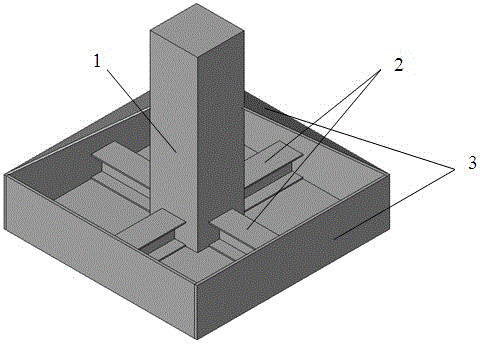

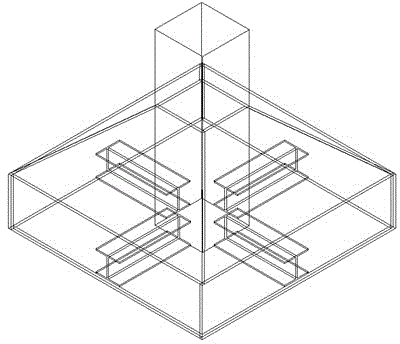

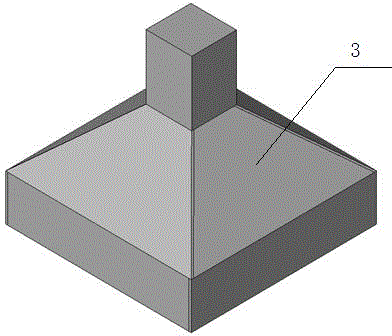

[0012] pass figure 1 It can be seen that the independent foundation of the movable assembled steel box of the present invention is composed of four sides of a box-shaped column 1 and four I-beams 2 to form a basic skeleton; the steel plate 3 is used as the bottom plate, side plate, and top plate The basic outer protective structure; there are openings and closing holes on the steel plate, and the counterweight can be increased or decreased according to the needs.

[0013] When the foundation needs to be moved, the counterweight in the steel box can be poured out from the reserved hole. At this time, the foundation becomes light. Lift the foundation with lifting lugs and move it to a new construction site for relocation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com