Moving shelter factory building adopting portal crane

A technology for gantry cranes and workshops, applied in industrial buildings, buildings, building structures, etc., can solve the problems of high cost, large one-time investment, waste of money, etc., and achieve high equipment utilization, high site utilization, and hoisting. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

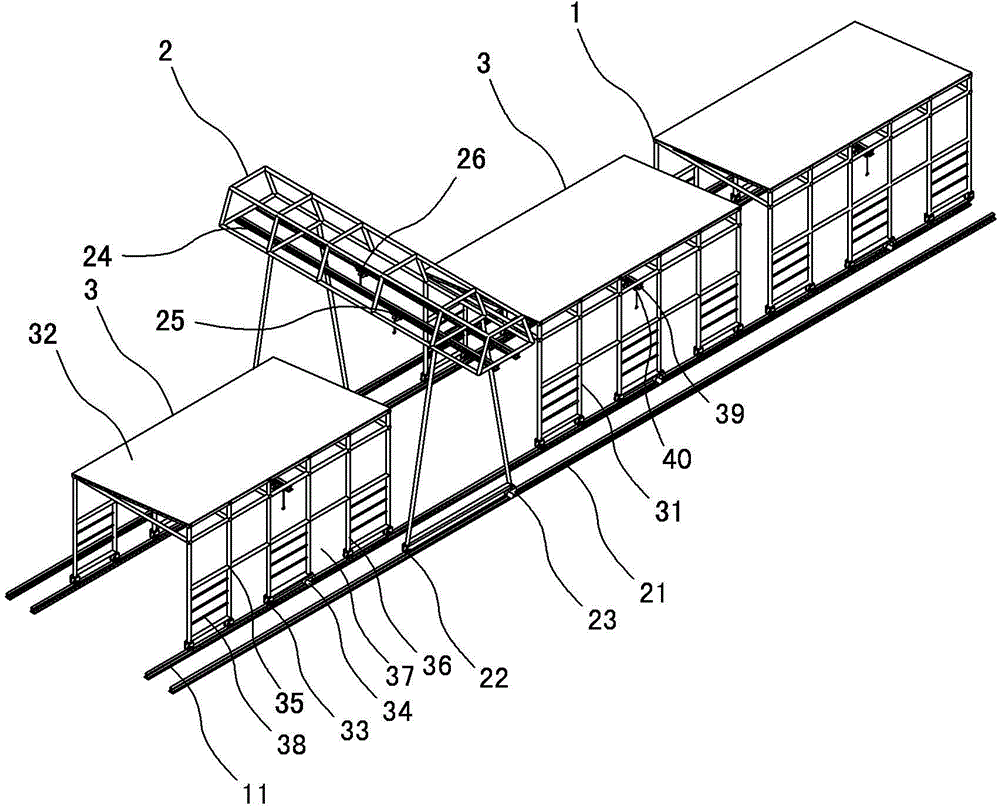

[0009] Such as figure 1 As shown, it comprises factory building 1 and gantry crane 2, is provided with several pairs of parallel factory building rails 11 between two gantry crane tracks 21, and factory building 1 is made of several movable sheds 3 that can move under gantry crane 2, each The mobile shed 3 is composed of a shed 31, a shed roof 32 that can prevent rain, snow and sun on the top of the shed 31, and several running wheels 33 that are rotatably installed at the bottom of the shed 31 and are matched with the factory building track 11. At least one traveling wheel 33 of each mobile shed 3 is connected with the driving mechanism 34 that links to each other with this traveling wheel 33 and drives it to rotate.

[0010] Scaffold 31 is made of two guardrail-like supports 35 erected in parallel along the direction of factory building track 11. The top of each guardrail-like support 35 is connected with shed roof 31 respectively, and the lower edge is provided with walkin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com