Bicycle lead casing

A wire and sleeve technology, which is applied in the field of wire sleeves for vehicles, can solve the problems of rigid cable structure, insufficient bendability, breakage, etc., and achieve the effects of enhanced impact resistance, good bending elasticity, and stable overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following examples illustrate possible implementations of the present invention, but they are not intended to limit the protection scope of the present invention and are described in advance.

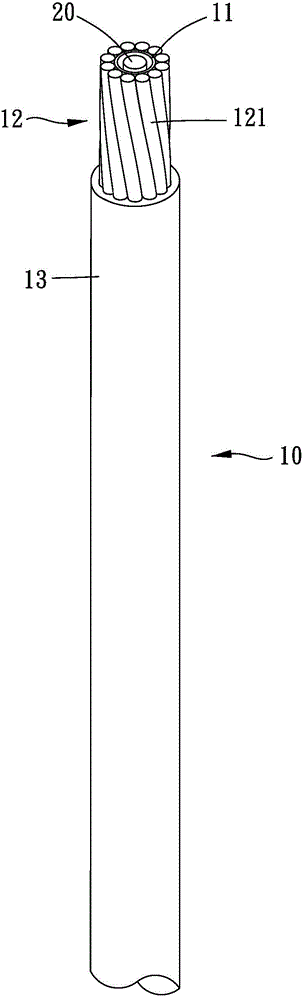

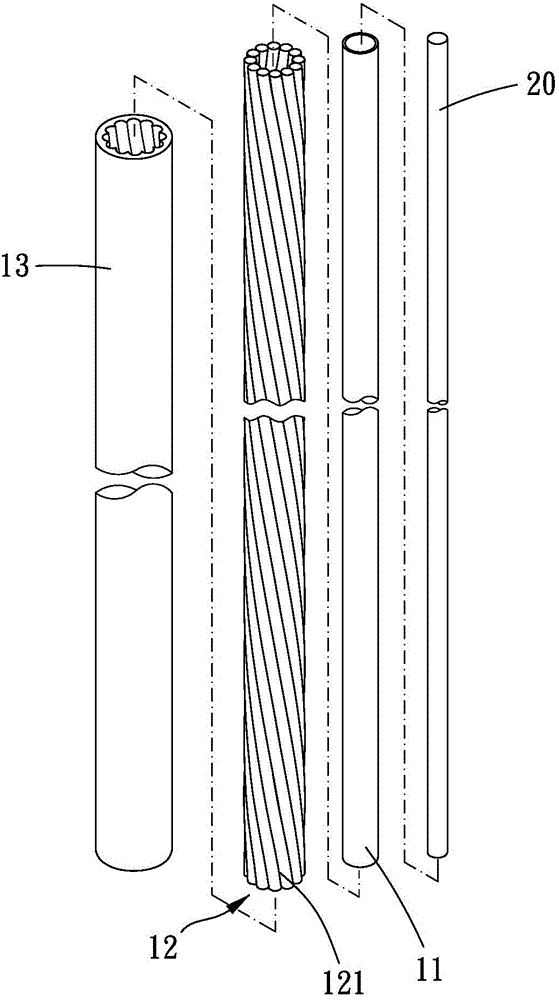

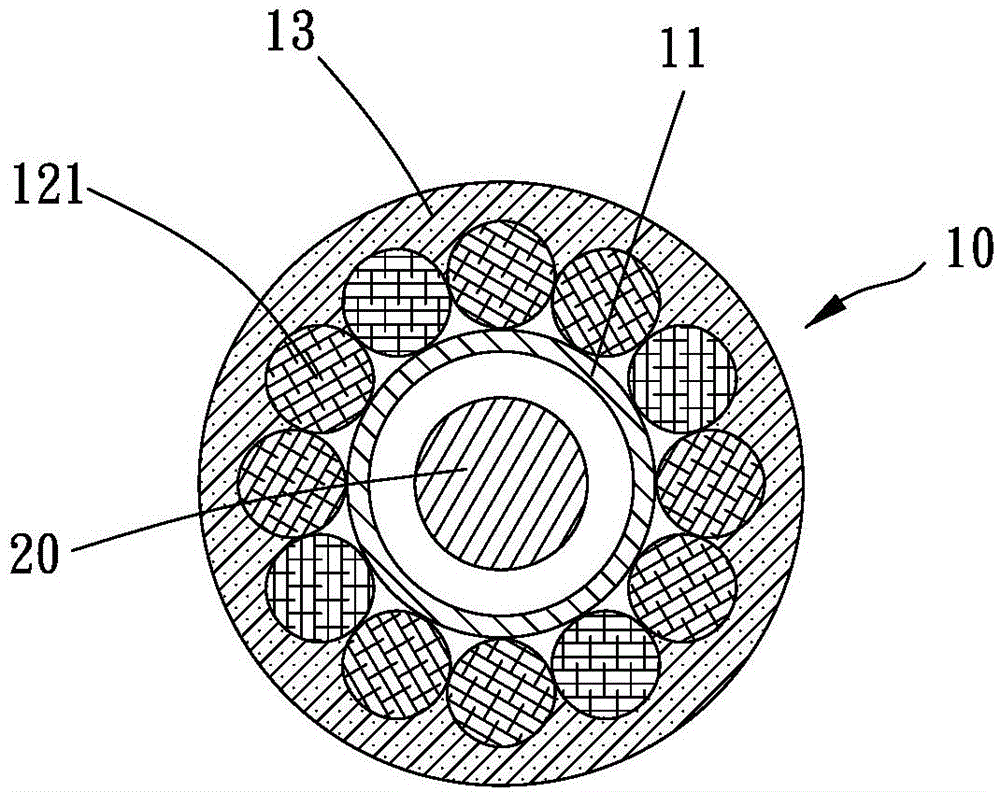

[0023] Please refer to Figure 1 to Figure 3 , the present invention provides a wire bushing 10 for a vehicle, comprising an inner tube 11 , a fiber layer 12 and an outer coating 13 .

[0024] The inner tube 11 has a cavity for a bicycle wire 20 to pass through, and its material is preferably polyethylene, Teflon or plastic steel; the fiber layer 12 is arranged and wound around the inner tube 11 by a plurality of strands 121 The inner tube 11 is formed, each of the strands 121 is made of glass fiber, and the outer surface of the fiber layer 12 is formed with a plurality of concave slots between the strands 121. In more detail, generally speaking , each of the strands 121 is cylindrical, so even if the plurality of strands 121 are closely connected to each other, the outer su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com