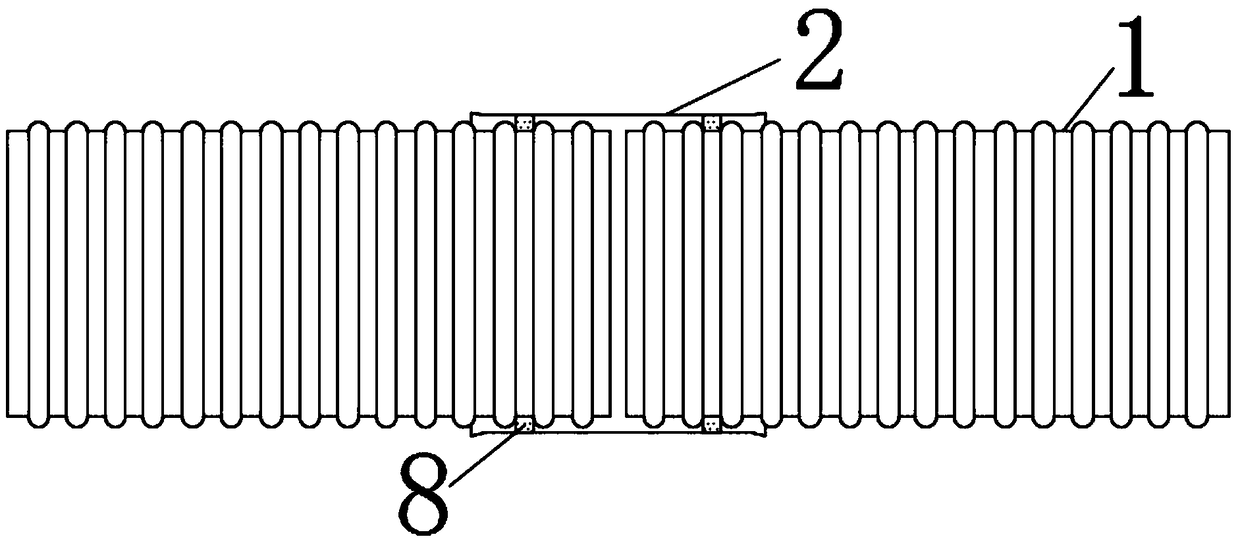

Continuous production of PP double-wall corrugated pipe with high-bending elastic modulus and production method thereof

A bending elastic modulus, double-wall bellows technology, applied in the direction of hoses, pipes, tubular objects, etc., can solve the problems of poor impact resistance, affecting service life, and small bending elasticity, and achieve high tensile strength, Improve the elasticity of the outer wall and the effect of good bending elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A kind of high flexural elastic modulus continuous production PP double-wall corrugated pipe of the present invention comprises the following steps during production:

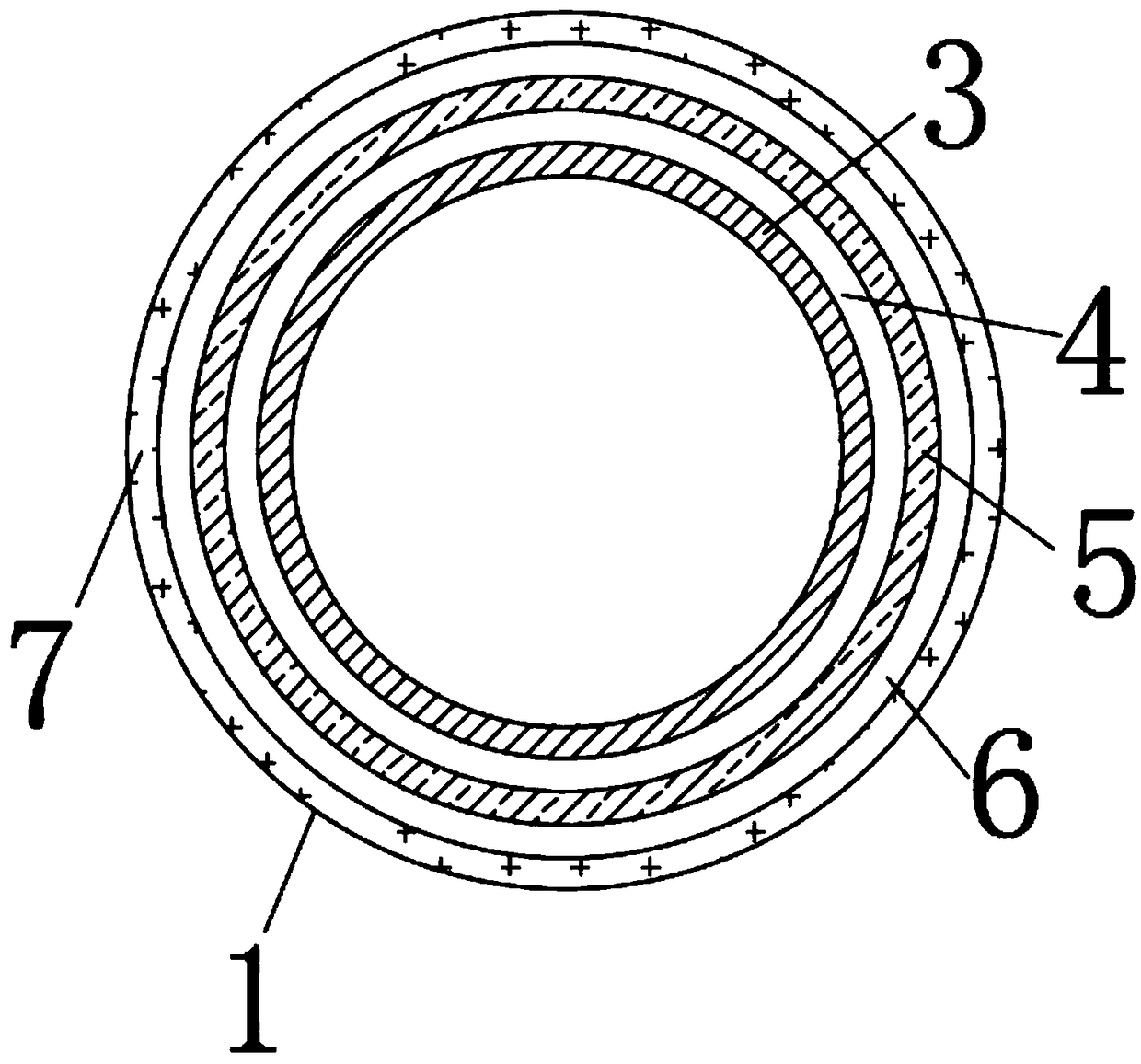

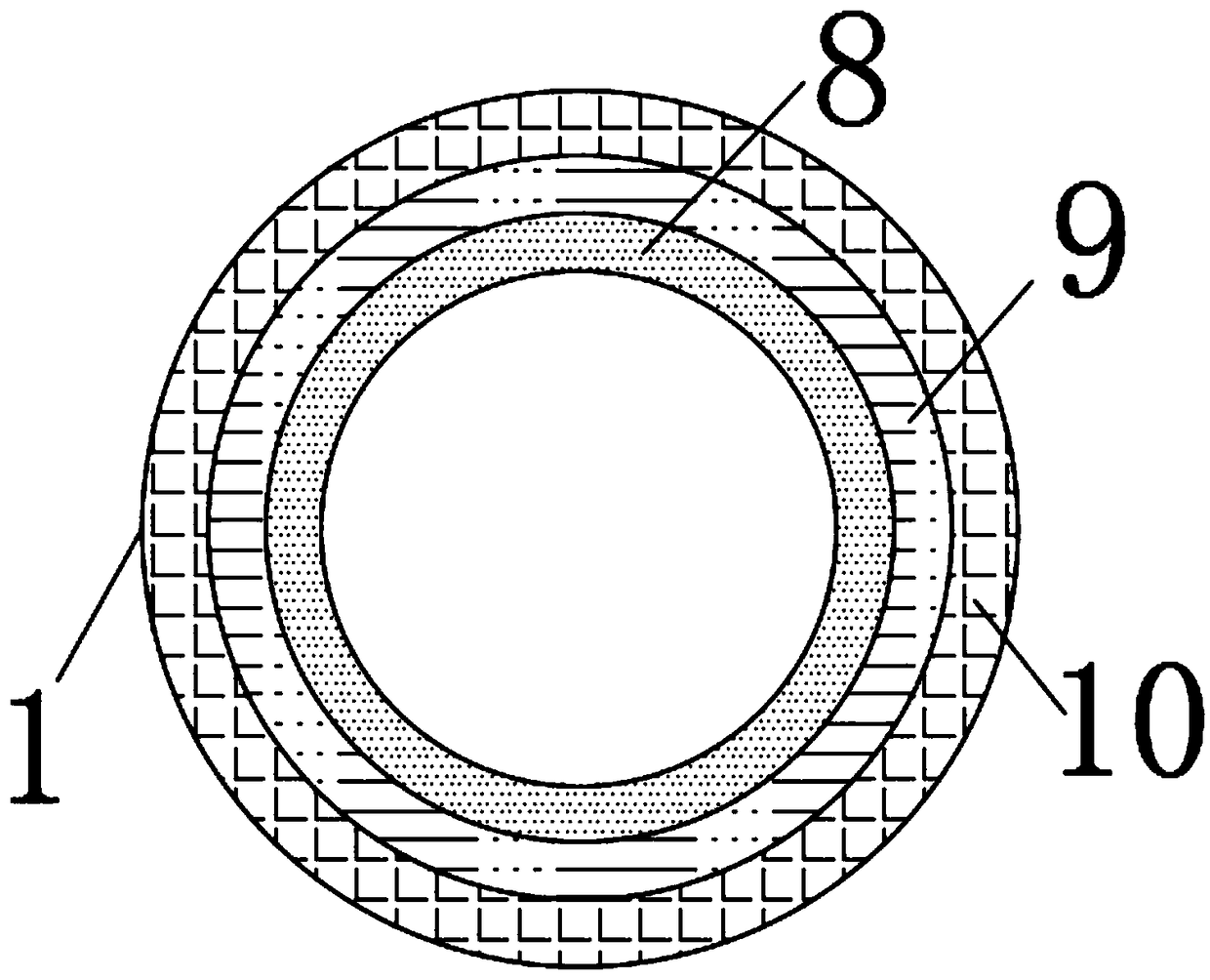

[0042] It includes an inner wall tube and an outer wall tube. Calculated by weight ratio, the composition of the inner wall tube includes 100 parts of polypropylene resin, 10 parts of recycled materials, 20 parts of high elastic water-based polyurethane resin, 2 parts of isocyanate curing agent, heavy carbonic acid 30 parts of calcium, 10 parts of stearic acid, 5 parts of desiccant, 5 parts of blue mother, 10 parts of talcum powder; the composition of the outer wall tube includes 100 parts of polypropylene resin, 10 parts of recycled materials, 15 parts of natural rubber, 1 part of vulcanizing agent, 1 part of accelerator, 40 parts of light calcium carbonate, 10 parts of stearic acid, 5 parts of desiccant, 5 parts of black masterbatch, 10 parts of talcum powder.

[0043] S1. Material preparation: Prepare...

Embodiment 2

[0052] A kind of high flexural elastic modulus continuous production PP double-wall corrugated pipe of the present invention comprises the following steps during production:

[0053] Including an inner wall tube and an outer wall tube, calculated by weight ratio, the composition of the inner wall tube includes 110 parts of polypropylene resin, 12 parts of recycled materials, 25 parts of high elastic water-based polyurethane resin, 2.5 parts of isocyanate curing agent, heavy carbonic acid 55 parts of calcium, 15 parts of stearic acid, 7 parts of desiccant, 8 parts of blue mother, 15 parts of talcum powder; 1.5 parts of vulcanizing agent, 1.5 parts of accelerator, 50 parts of light calcium carbonate, 15 parts of stearic acid, 7 parts of desiccant, 8 parts of black masterbatch, 15 parts of talcum powder.

[0054] S1. Material preparation: Prepare the materials for the inner wall pipe and the outer wall pipe respectively according to the weight ratio.

[0055] Inner wall pipe mat...

Embodiment 3

[0063] A kind of high flexural elastic modulus continuous production PP double-wall corrugated pipe of the present invention comprises the following steps during production:

[0064] It includes an inner wall tube and an outer wall tube. Calculated by weight ratio, the composition of the inner wall tube includes 120 parts of polypropylene resin, 15 parts of recycled materials, 30 parts of high elastic water-based polyurethane resin, 3 parts of isocyanate curing agent, heavy carbonic acid 80 parts of calcium, 20 parts of stearic acid, 10 parts of desiccant, 10 parts of blue mother, 20 parts of talc; the composition of the outer wall tube includes 120 parts of polypropylene resin, 15 parts of recycled materials, 30 parts of natural rubber, 2 parts of vulcanizing agent, 2 parts of accelerator, 60 parts of light calcium carbonate, 20 parts of stearic acid, 10 parts of desiccant, 10 parts of black masterbatch, 20 parts of talcum powder.

[0065] S1. Material preparation: Prepare th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com