A low-pressure condensate flash steam condenser and system for an mtp device

A technology of steam condenser and condensate, which is applied in the field of low-pressure condensate flash steam condenser and system of the improved MTP device, which can solve the problems of large pressure drop of the condenser, large heat exchange area, and pressure rise of the flash tank, etc. , to achieve the effect of increasing the heat transfer temperature difference, reducing the heat transfer area, and reducing the overpressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

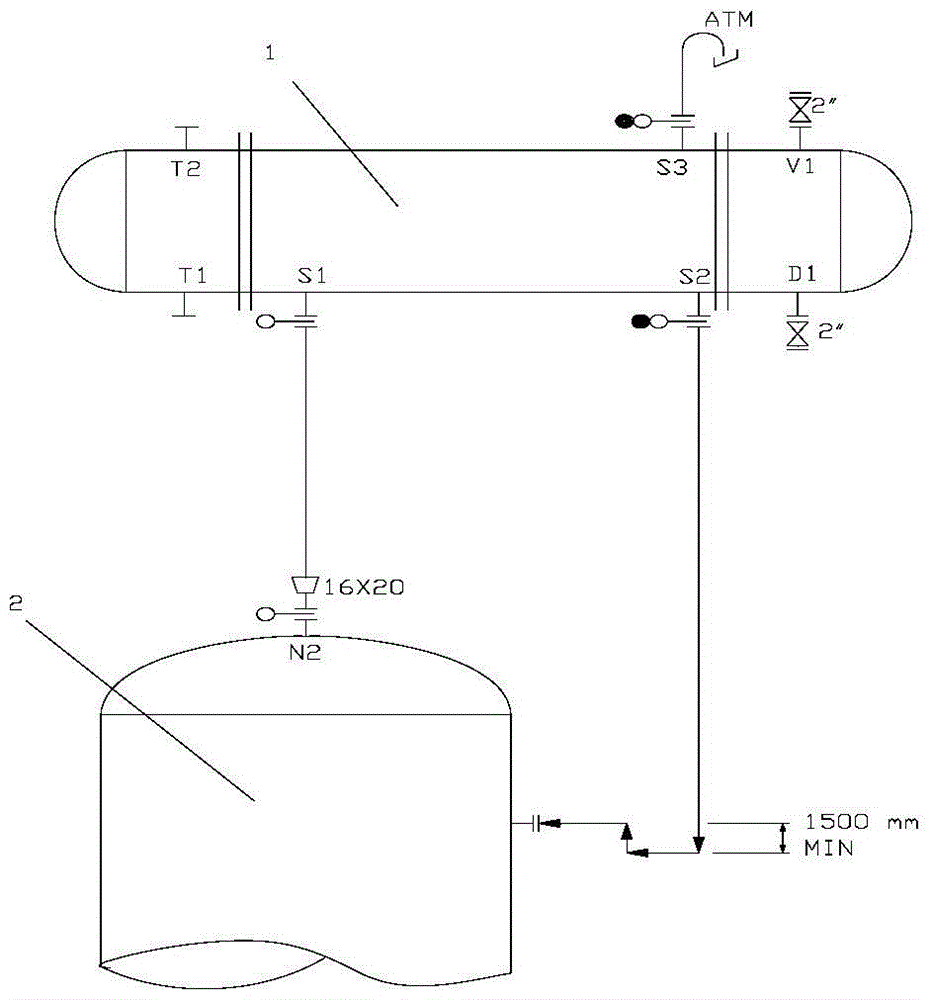

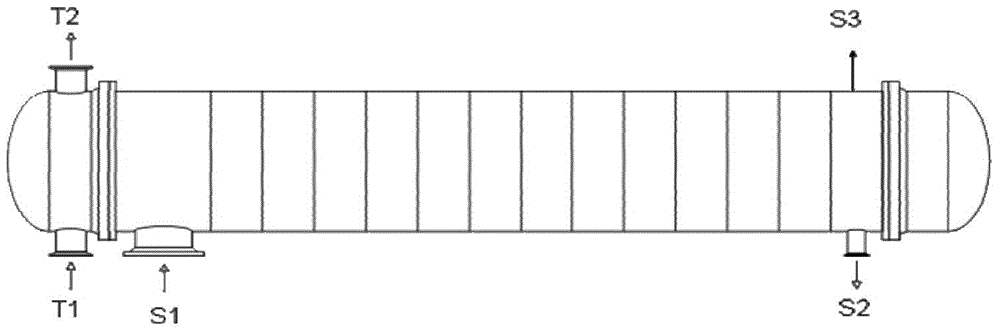

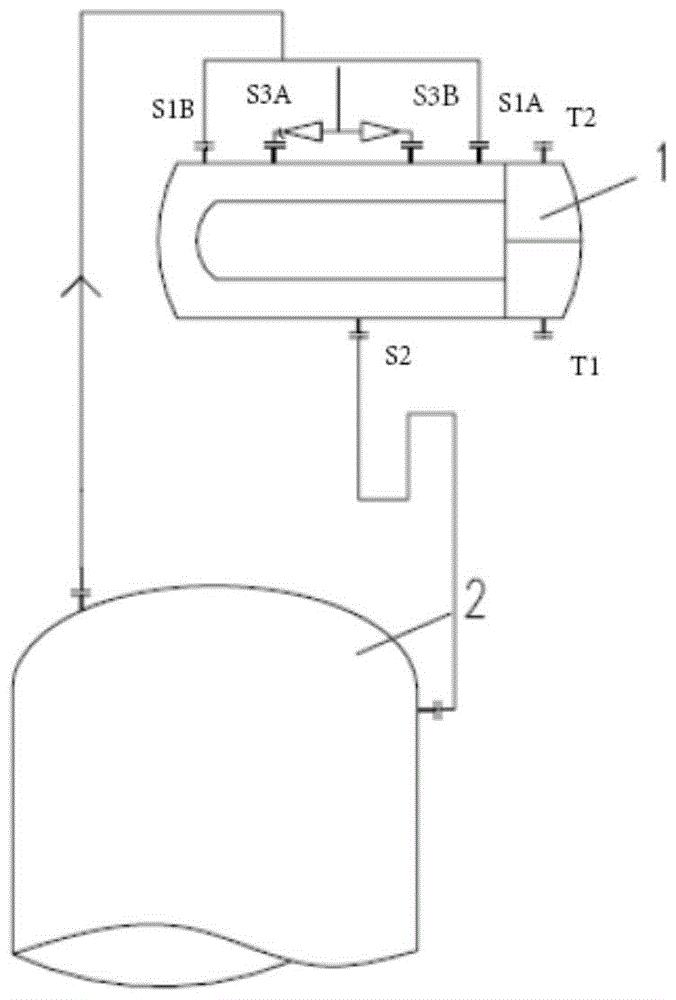

Embodiment 1

[0028] In the MTP plant with a scale of 500,000 tons / year of propylene, the low and low pressure condensate flash steam condenser in the atmospheric pressure condensate flash system, the steam volume from the flash tank is 46.8t / h, and the inlet temperature is 102℃ , the pressure is 99KPa, the required outlet temperature is 98°C, and the allowable pressure drop is 5KPa; the inlet and outlet temperatures of the cold medium desalinated water are 49°C and 87°C, respectively.

[0029] Using the existing steam condenser structure for design, the calculated pressure drop is 14KPa, the logarithmic average temperature difference is 23.5℃, and the required heat exchange area is 1190m 2 ;

[0030] The low-pressure condensate flash vapor condenser of the MTP device of the invention is used for design, the calculated pressure drop is 2KPa, the logarithmic average temperature difference is 26.2°C, and the required heat exchange area is 950m 2 ;

[0031] Therefore, under the industrial op...

Embodiment 2

[0033] In the 800,000 tons / year ethylene plant, the low and low pressure condensate flash steam condenser in the atmospheric condensate flash system, the steam volume from the flash tank is 21.43t / h, the inlet temperature is 105°C, and the pressure is 120KPa, the outlet temperature is required to be 100°C, and the allowable pressure drop is 20KPa; the inlet and outlet temperatures of the cold medium desalinated water are 54°C and 92°C, respectively.

[0034] Using the existing steam condenser structure to design, the calculated pressure drop is 13KPa, the logarithmic average temperature difference is 25.1℃, and the required heat exchange area is 791m 2 ;

[0035] The steam condenser proposed by the present invention is used for design, the calculated pressure drop is 2KPa, the logarithmic average temperature difference is 26.9°C, and the required heat exchange area is 712m 2 ;

[0036] Therefore, under the industrial operating conditions described in this example, the low-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com