Abnormal engine sound fault on-line diagnostic system and diagnostic method

A technology of a diagnostic system and a diagnostic method, which is applied in the testing of engines, testing of machinery/structural components, measuring devices, etc., can solve the problem of difficulty in ensuring the accuracy of complex abnormal noise fault identification, lack of multi-index cross-judgment, and abnormal noise characteristic indicators. Single problem, to achieve the effect of efficient fault diagnosis, wide coverage and fast diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

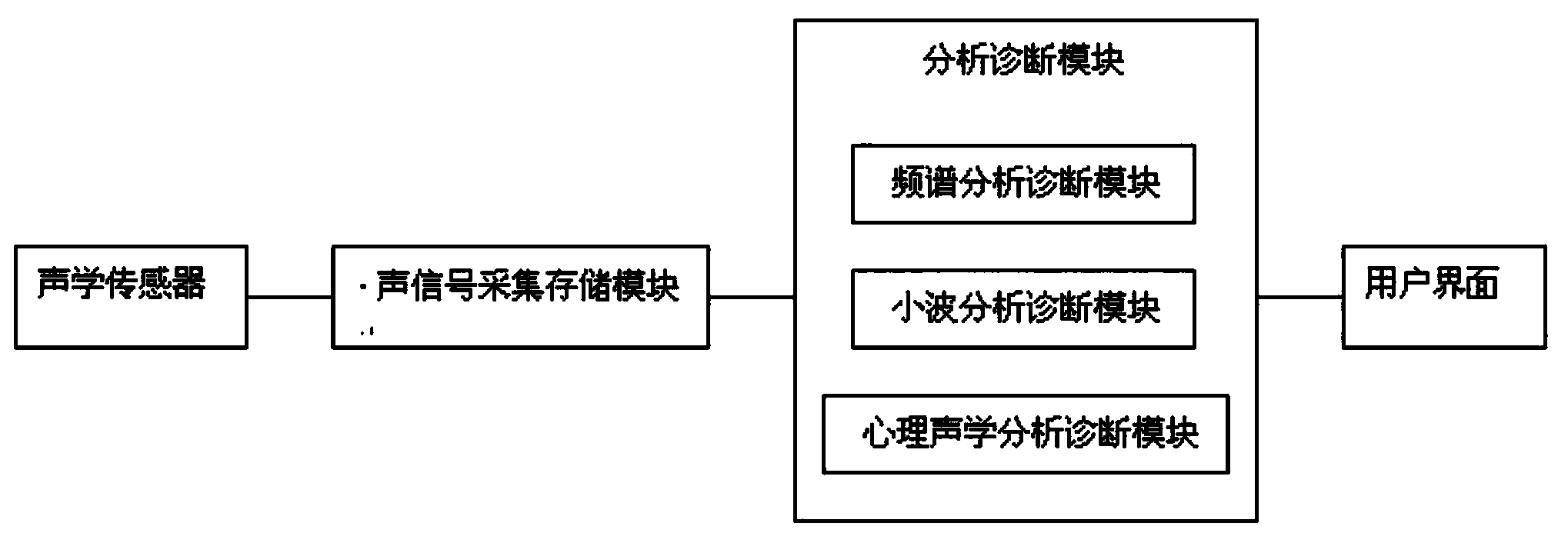

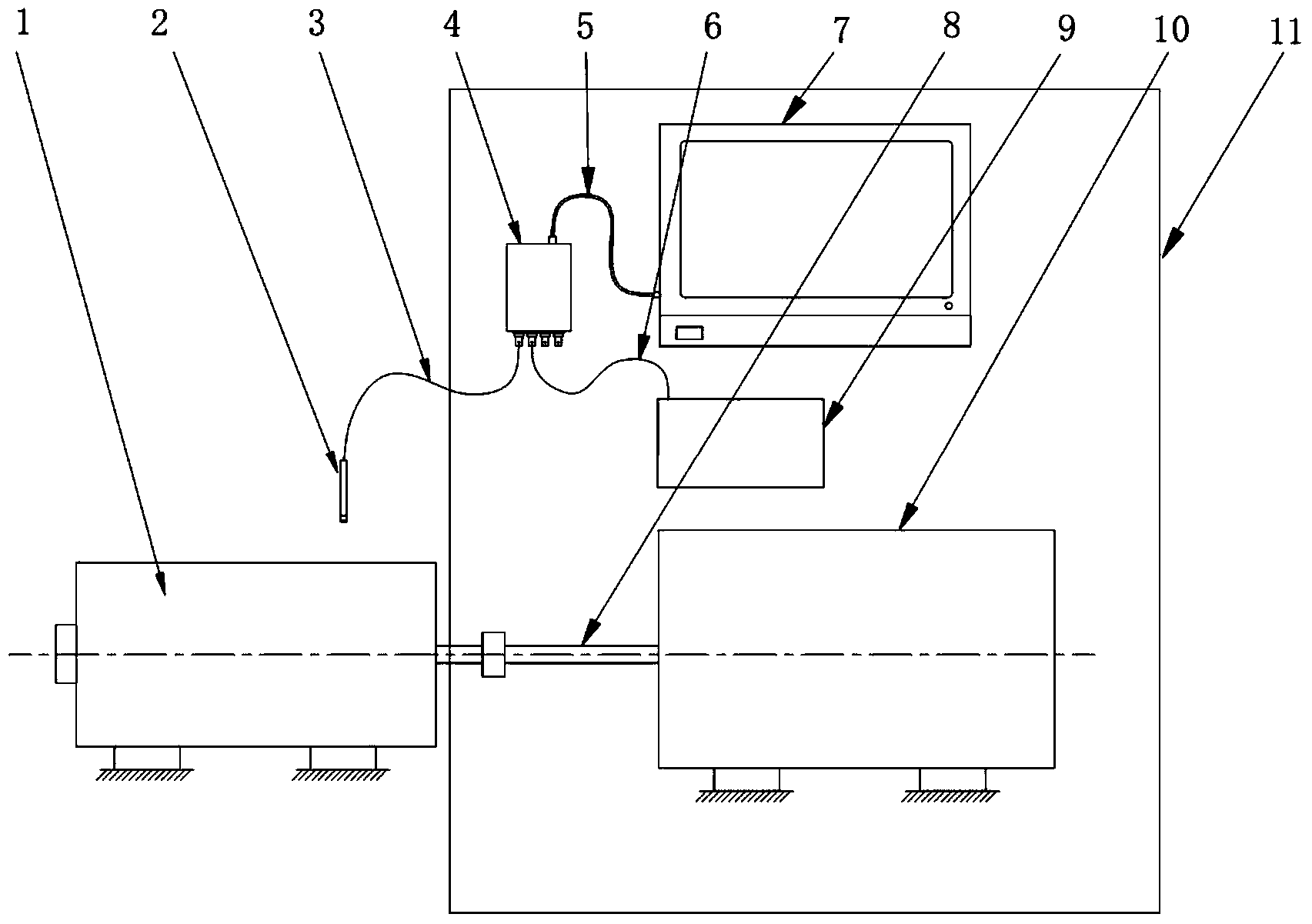

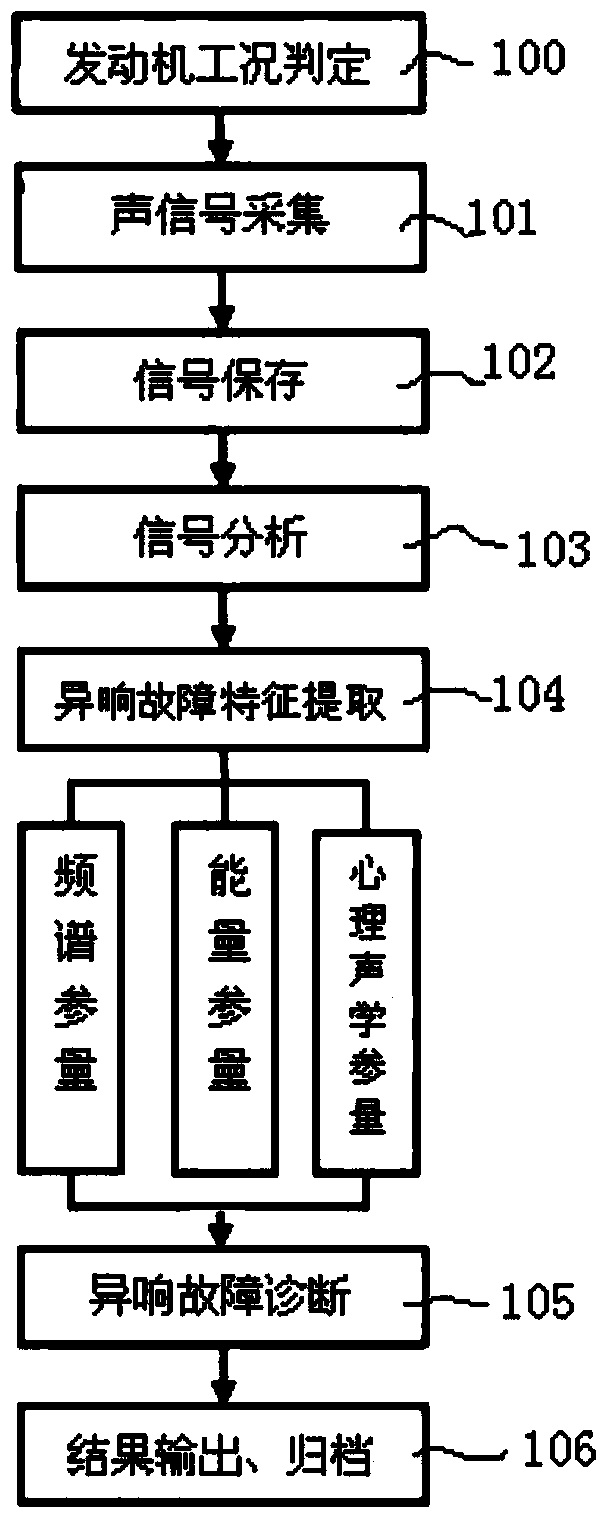

[0035] Such as figure 1 As shown, the present invention is an online diagnosis system for engine abnormal sound faults, which includes a connected acoustic sensor, an engine working condition judgment module, an acoustic signal acquisition and storage module, and an analysis and diagnosis module. The acoustic sensor is one and is installed at a fixed position on the side of the engine block for detection. When the engine working condition judging module judges that the engine is in an idling condition, the acoustic signal is collected; the analyzing and diagnosing module includes obtaining Spectrum analysis and diagnosis module of spectral parameters, wavelet analysis and diagnosis module of obtaining energy parameters through wavelet analysis, and psychoacoustic analysis and diagnosis module of obtaining psychoacoustic parameters through psy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com