Tube wall plane indentation residual thickness expanding device for tube material mechanic performance test and test method

A technology of plane indentation and test tube, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., to achieve the effect of simplifying the test device, testing safety, and simplifying the test device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

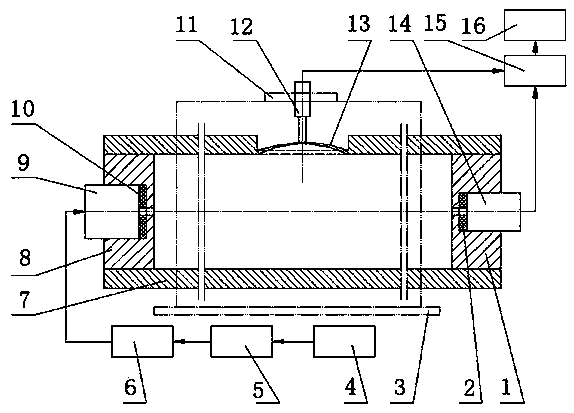

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

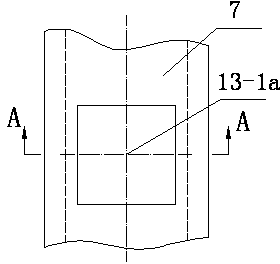

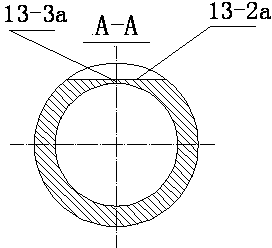

[0035] refer to figure 1 , the pressure transmitter side plug 1, the liquid inlet side plug 8 and the test pipe section 7 form a pressurized space for the bulging test. The test pipe section 7 needs to control the minimum length according to the influence of the pipe end. The liquid inlet joint 9 and the liquid inlet side gasket 10 forms a seal on the liquid inlet side, and the pressure transmitter 14 and the pressure transmitter side gasket 2 form a seal on the other side. The test pipe section 7 is fixed by the pipe section support frame 3. On the central point of the pipe wall excess thickness bulging area 13, a linear displacement sensor 12 is arranged in the normal direction, and is fixed by the displacement sensor positioning frame 11 to ensure that it is consistent with the initial pipe wall thickness bulging area 13. The verticality of the plane.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com