Automatic thermal conductivity coefficient measurement equipment based on thermoelectric semiconductor

A technology of thermoelectric semiconductor and thermal conductivity, applied in the direction of thermal development of materials, etc., can solve problems such as inaccurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

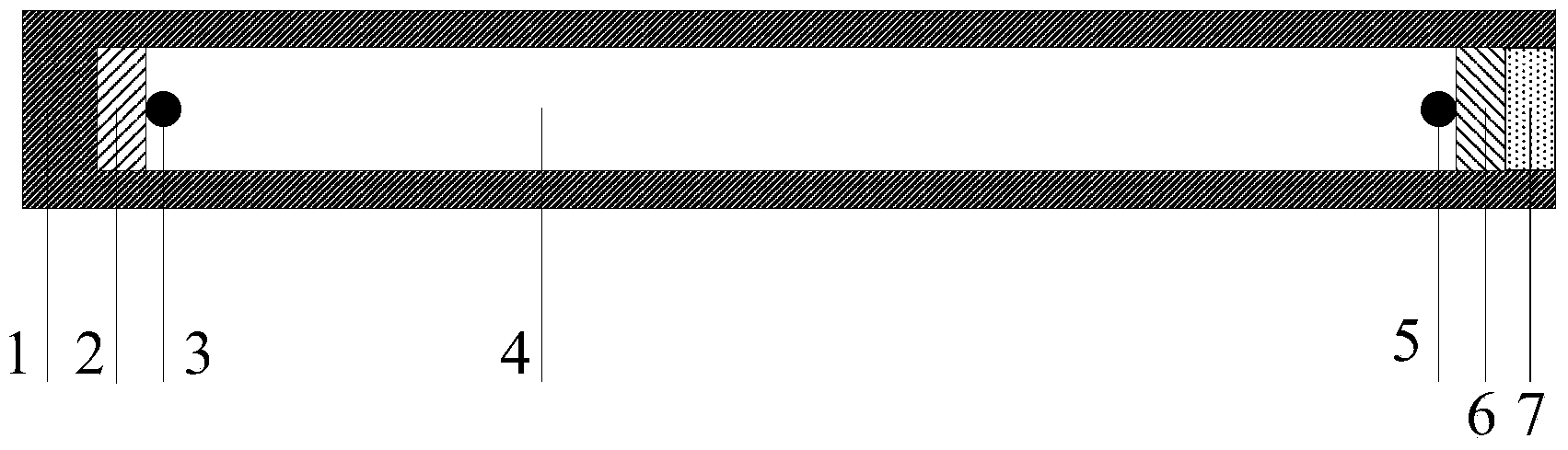

[0055] figure 1 It is a schematic diagram of a sample tube of a thermal conductivity measuring device according to an embodiment of the present invention. like figure 1 As shown, the sample tube for containing the sample 4 includes: a thermal insulation jacket 1 , a heating device 2 , a first temperature sensor 3 , a second temperature sensor 5 , and a thermoelectric semiconductor 6 . Optionally, the sample tube may also include a heat dissipation block 7 .

[0056] like figure 1 As shown, the heat insulating sleeve 1 forms a barrel-shaped structure with one end closed, such as a barrel or a square barrel, for accommodating a heating device 2 , a first temperature sensor 3 , a sample 4 , a second temperature sensor 5 , and a thermoelectric semiconductor 6 . One end of the heat insulating sleeve 1 is open, and the other end is closed. The opening and sealing mentioned here are for heat conduction, and the sealing refers to thermal sealing, that is, it can realize heat insul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com