Aerial coolant cold source system

A coolant and cold source technology, which is applied in the field of aviation coolant cold source system, can solve the problem that the output power of the pump body cannot be adjusted in time, and achieve the effects of reducing emissions, saving costs, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

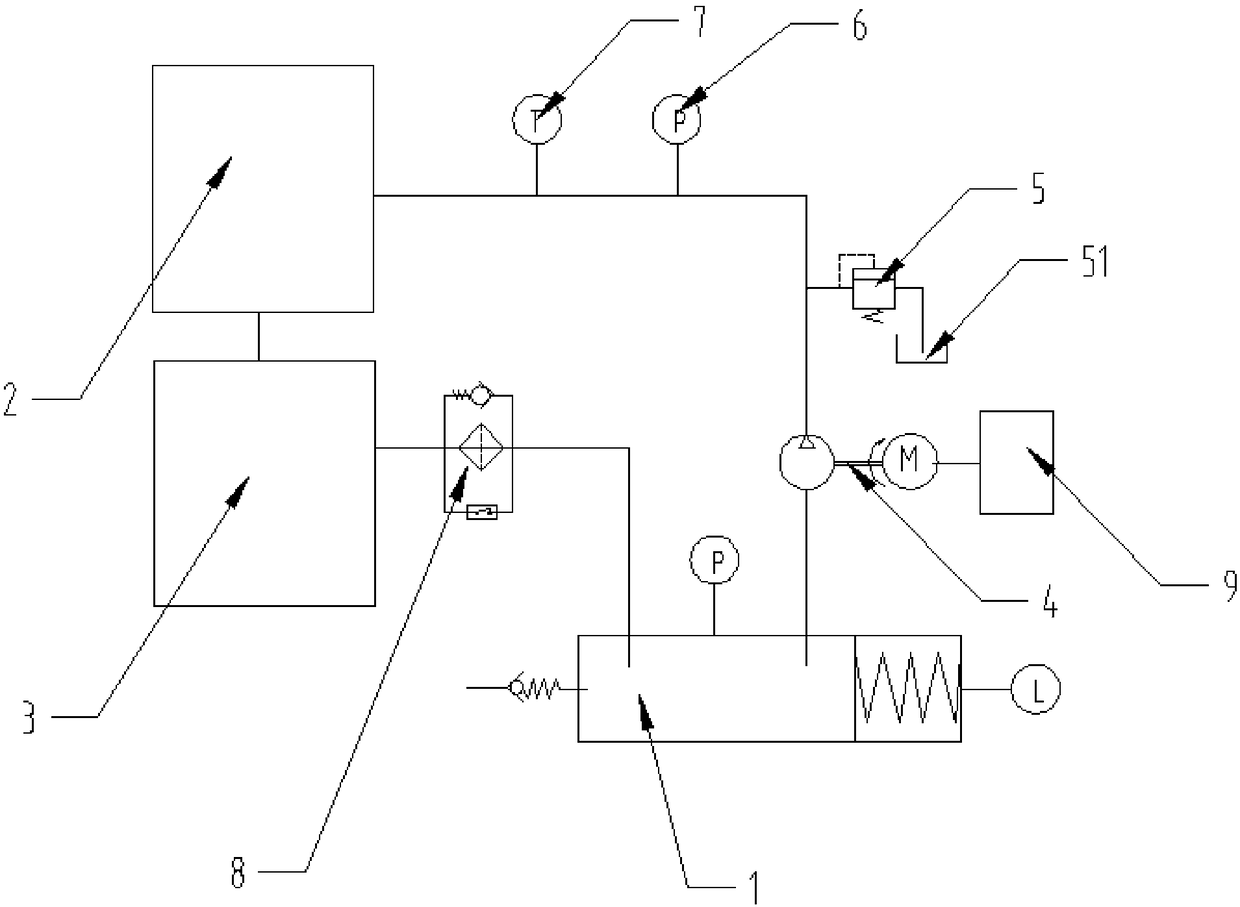

[0045] The technical solution of this embodiment is: an aviation coolant cold source system, including a pressurized liquid storage assembly 1, a pump set 4, a heat load 2, a heat sink 3, and a filter assembly 8 connected end to end in sequence; Component 1, pump set 4, heat load 2, cooling device 3 and filter component 8 are connected in sequence through pipelines and form a circulation system;

[0046] A safety valve 5, a second pressure sensor 6 and a temperature sensor 7 are sequentially arranged on the pipeline between the pump group 4 and the heat load 2 from the pump group 4 along the direction of the heat load 2;

[0047] A liquid outlet pipe is connected to the liquid outlet of the safety valve 5, and a liquid storage tank 51 is arranged below the outlet of the liquid outlet pipe.

[0048] Such asfigure 1 As shown, the coolant stored in the pressurized liquid storage assembly 1 is pumped out by the pump group 4 into the pipeline for circulation. When the pressure at t...

Embodiment 2

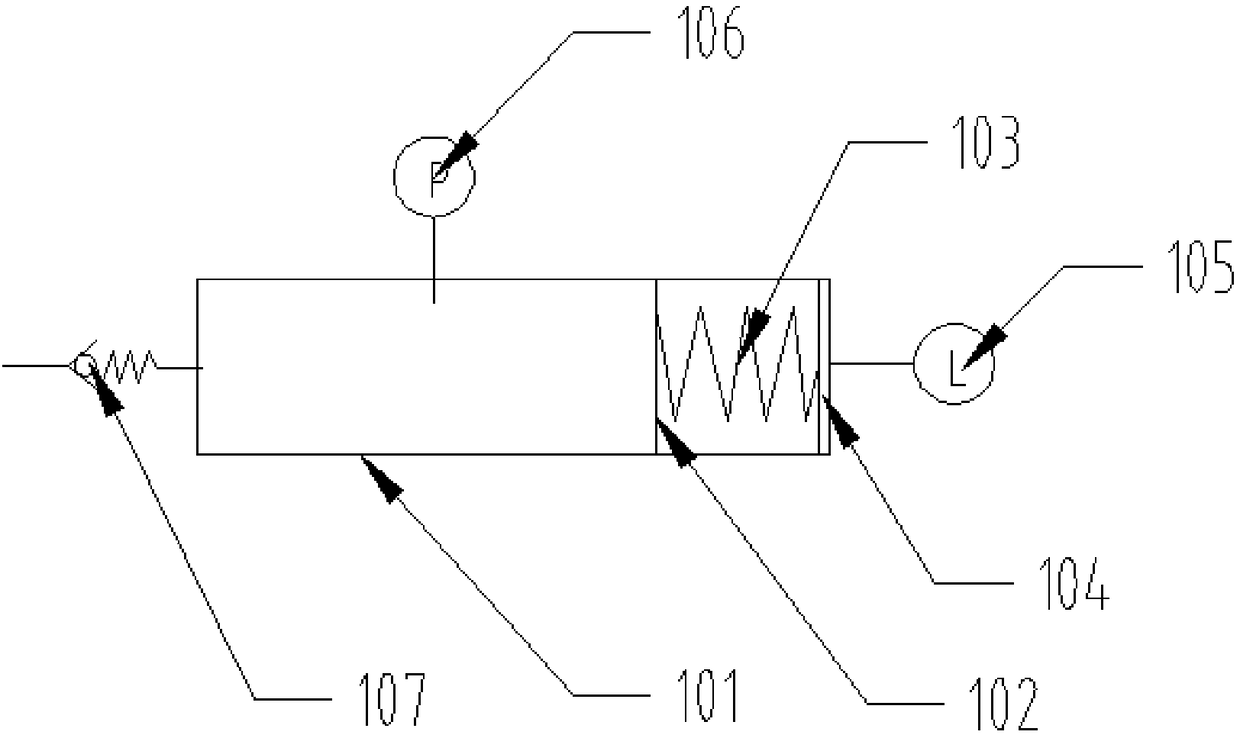

[0050] On the basis of Embodiment 1, the technical solution of this embodiment is: the pressurized liquid storage assembly 1 includes a liquid storage tank 101, and a displacement sensor 104 and a booster spring are sequentially arranged in the liquid storage tank 101 from one end to the other end 103 and the piston assembly 102.

[0051] Such as figure 2 As shown, the displacement sensor 104 measures the moving distance of the booster spring 103, thereby reflecting the increased pressure of the coolant in the liquid storage tank 101, which is used to increase the pressure of the coolant entering the pump set 4, so that the pressure of the pump set 4 outlet The pressure of the coolant is not too low.

Embodiment 3

[0053] Based on the first embodiment, the technical solution of this embodiment is that the liquid storage tank 101 is provided with a liquid injection valve 107 , a first pressure sensor 106 and a liquid level sensor 105 .

[0054] Such as figure 2 As shown, the first pressure sensor 106 is used to measure the pressure of the cooling liquid in the liquid storage tank 101, and the liquid injection valve 107 is used to supplement the amount of cooling liquid in the liquid storage tank 101, so as to avoid the change of the cooling liquid volume caused by the temperature change , the liquid level sensor 105 responds to the change in the volume of the cooling liquid in the liquid storage tank 101 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com