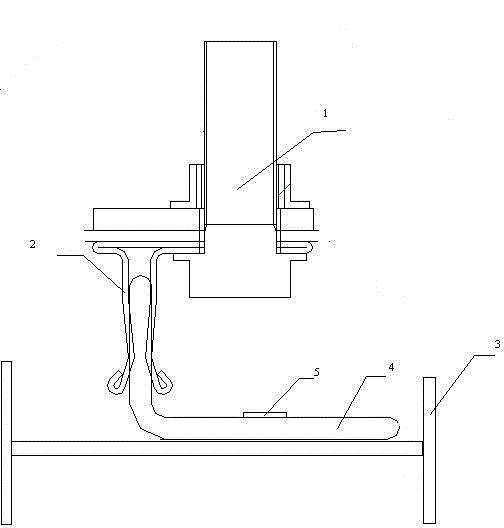

Grounding system of XP intensive bus duct and jack box

A grounding system and busway technology, applied in the direction of connecting parts such as protective grounding/shielding devices, can solve the problems of poor grounding continuity of the busbar, cumbersome installation, easy omission, etc., to ensure grounding continuity, beautiful appearance, fast and stable installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

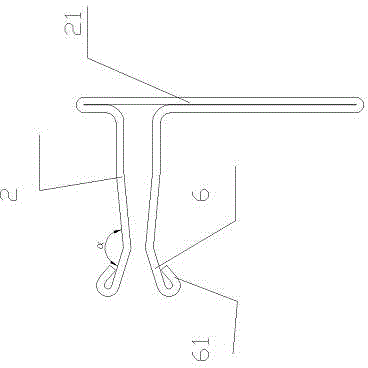

[0012] A grounding system for an XP-intensive busway and a plug-in box, including a grounding pin 2 installed on the box body 1 of the plug-in box, and a grounding bar 4 riveted and fixed on the cover plate 3 of the busway through a rivet 5. When connecting, The grounding bar 4 is inserted into the grounding pin 2 , and the grounding bar 4 is an L-shaped component, or other shaped components. In order to make the connection between the ground bar 4 and the ground pin 2 more firm, the ground pin 2 includes a bottom plate 21, and the bottom plate 21 is provided with clamping pins 22, and the clamping pins 22 are fixed vertically on the bottom plate 21. Above, the clamping pins 22 are parallel to each other to form a clamping part for plugging in the ground bar 4, and the corresponding clamping pins 2 are provided with a corresponding clamping part 6 at the bottom end, and the clamping parts 6 and the clamping pins The joint of 2 forms a clamping place, and an angle α is set betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com