Fire prevention bus duct

A technology of bus duct and fireproof board, applied in the field of bus duct, can solve the problems of affecting the mechanical properties and life of the bus duct, poor corrosion resistance, unfavorable waterproofing, etc., and achieve the effect of prolonging the service life, ensuring the fire resistance and reducing the weight of the product.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

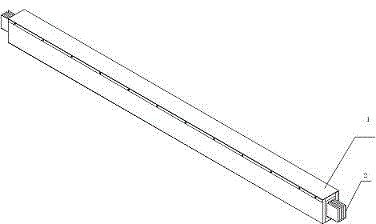

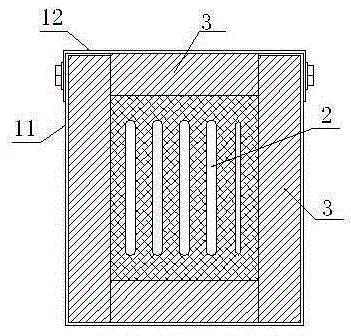

[0011] A fireproof busway, comprising a housing 1, the housing 1 is fixed with a main busbar 2, the inner wall of the housing 1 is fixed with a fireproof board 3, and the main busbar 2 is passed through the cast epoxy plastic ester Fixed in the housing 1, the housing 1 includes a U-shaped lower housing 11, a U-shaped upper cover 12, the U-shaped upper cover 12 is arranged on the U-shaped lower housing 11, the U-shaped The U-shaped lower shell and the U-shaped upper cover are connected into one body by bolts; the structure of the fireproof busway of this structure is simpler and the connection is convenient. A fireproof paint layer is provided between the fireproof board 3 and the housing 1 . Since the housing is provided with a fireproof board 3 and sprayed with a fireproof paint layer, the fireproof capability of the bus duct is guaranteed. During the production process, anti-corrosion materials such as epoxy plastic ester are used to fix the main busbar 2 components to enhan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com