Preparation process for wet rice vermicelli with long shelf life

A technology for preparation process and shelf life, applied in the field of preparation technology of wet rice noodles, can solve problems such as health effects and achieve the effect of food safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

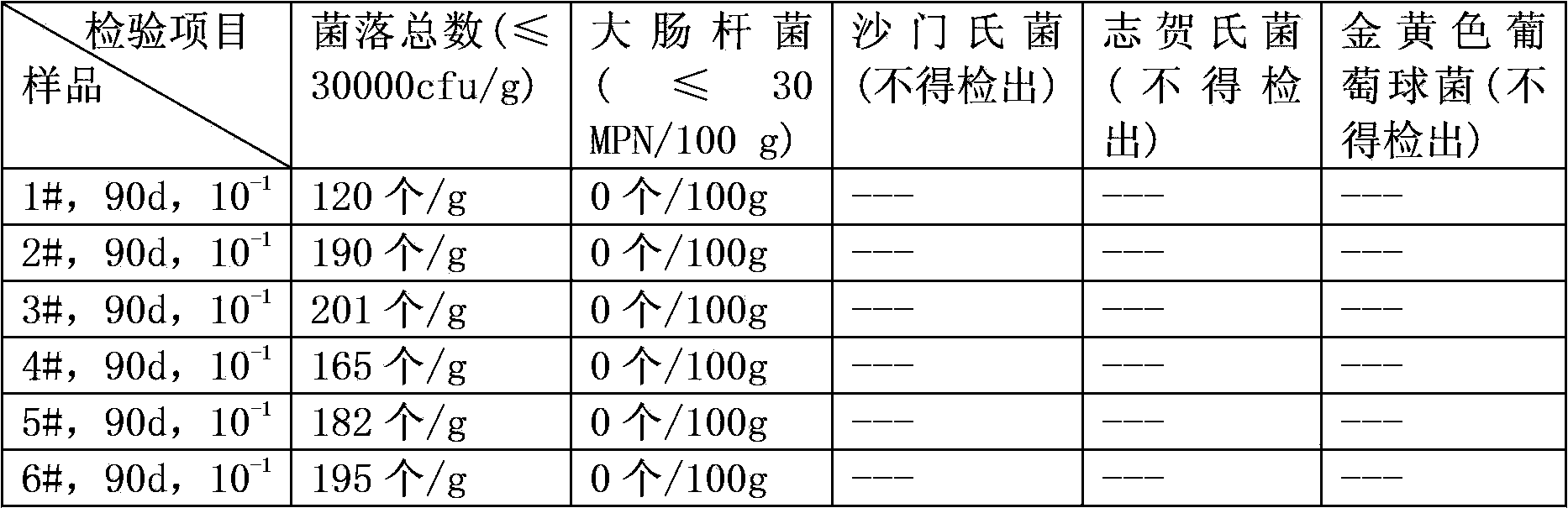

Examples

Embodiment 1

[0020] 1) Take the rice, wash and remove the stones and sand grains therein, soak for 3 hours, drain, and pulverize to 60 mesh to obtain rice flour;

[0021] 2) Add ginger essential oil accounting for 0.3‰ of the weight of rice noodles and cinnamon oil accounting for 0.1‰ of the weight of rice noodles to the rice noodles. After mixing evenly, send them to a self-cooked double-barrel vermicelli machine for extrusion molding, and cut according to the length of 50cm to obtain vermicelli; in:

[0022] The ginger essential oil is prepared by the following method: take dried ginger and pulverize it to 50 mesh, distill and extract for 2.5 hours, separate the oil and water from the obtained fraction, and collect the oily substance as ginger essential oil;

[0023] The cinnamon oil is prepared by the following method: cinnamon bark is crushed to 60 mesh, distilled and extracted for 2 hours, the obtained fraction is separated from oil and water, and the oily matter is collected as cinna...

Embodiment 2

[0026] 1) Take the rice, wash and remove the stones and grits therein, soak for 2 hours, drain, and pulverize to 40 mesh to obtain rice noodles;

[0027] 2) Add ginger essential oil accounting for 0.5‰ of the weight of rice noodles and cinnamon oil accounting for 0.2‰ of the weight of rice noodles to the rice noodles. After mixing evenly, send them to a self-cooked double-barrel vermicelli machine for pressing and molding, and cut according to the length of 50cm to obtain vermicelli; in:

[0028] The ginger essential oil is prepared by the following method: take dried ginger and crush it to 50-60 meshes, distill and extract for 3 hours, separate the obtained fractions from oil and water, and collect the oily matter as ginger essential oil;

[0029] The cinnamon oil is prepared by the following method: cinnamon bark is crushed to 40 meshes, distilled and extracted for 3 hours, the obtained fraction is separated from oil and water, and the oil is collected as cinnamon oil;

[0...

Embodiment 3

[0032] 1) Take the rice, wash and remove the stone grit therein, soak for 5 hours, drain, and pulverize to 50 mesh to obtain rice flour;

[0033] 2) Add ginger essential oil (produced by Zhengzhou Xuemailong Food and Spice Co., Ltd.) accounting for 0.1‰ weight of rice noodles and cinnamon oil (Hengxian Ruifeng Spice Co., Ltd.) accounting for 0.2‰ weight of rice noodles to the rice noodles. The self-cooked double-tube vermicelli machine is pressed and shaped, and cut according to a length of 50 cm to obtain vermicelli;

[0034] 3) The obtained vermicelli was aged at 28° C. for 10 hours, then soaked in 90° C. water for 1.5 hours, taken out, subpackaged into 0.5 kg / bag, and pasteurized for 70 minutes to obtain the wet rice noodles of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com