Working safety helmet with refrigerating system

A refrigeration system and safety helmet technology, applied in the field of safety helmets, can solve the problems of low refrigeration efficiency and unsatisfactory refrigeration effect, and achieve the effects of improving utilization rate, wearing safety, and enhancing protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

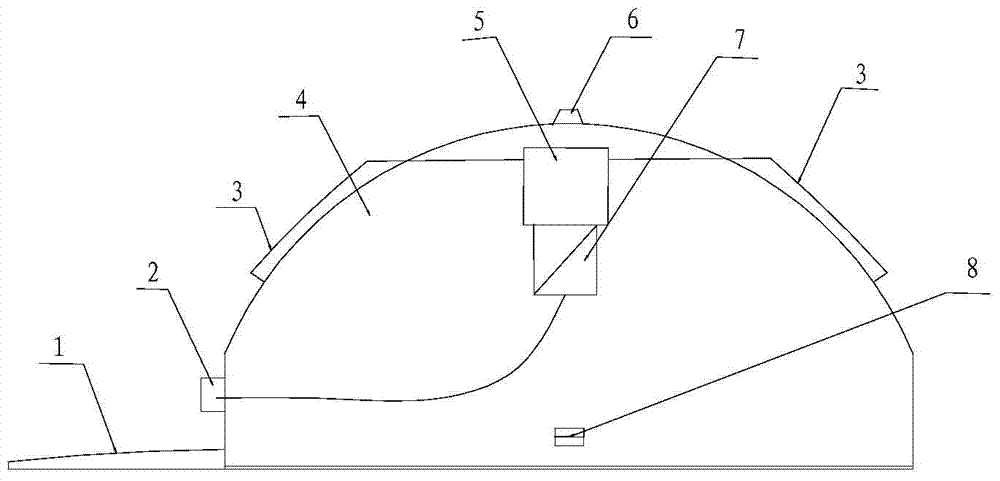

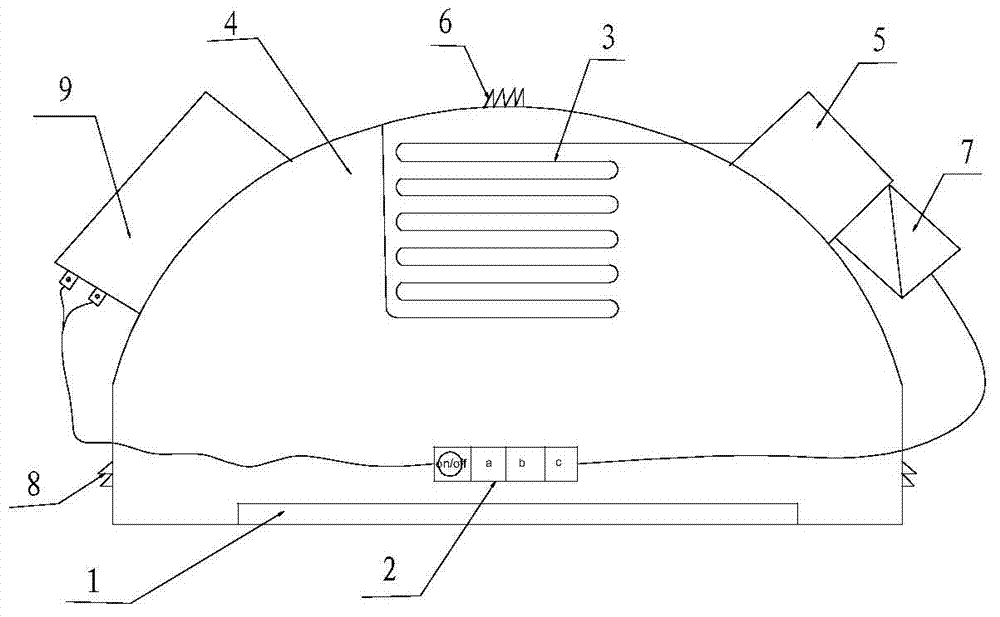

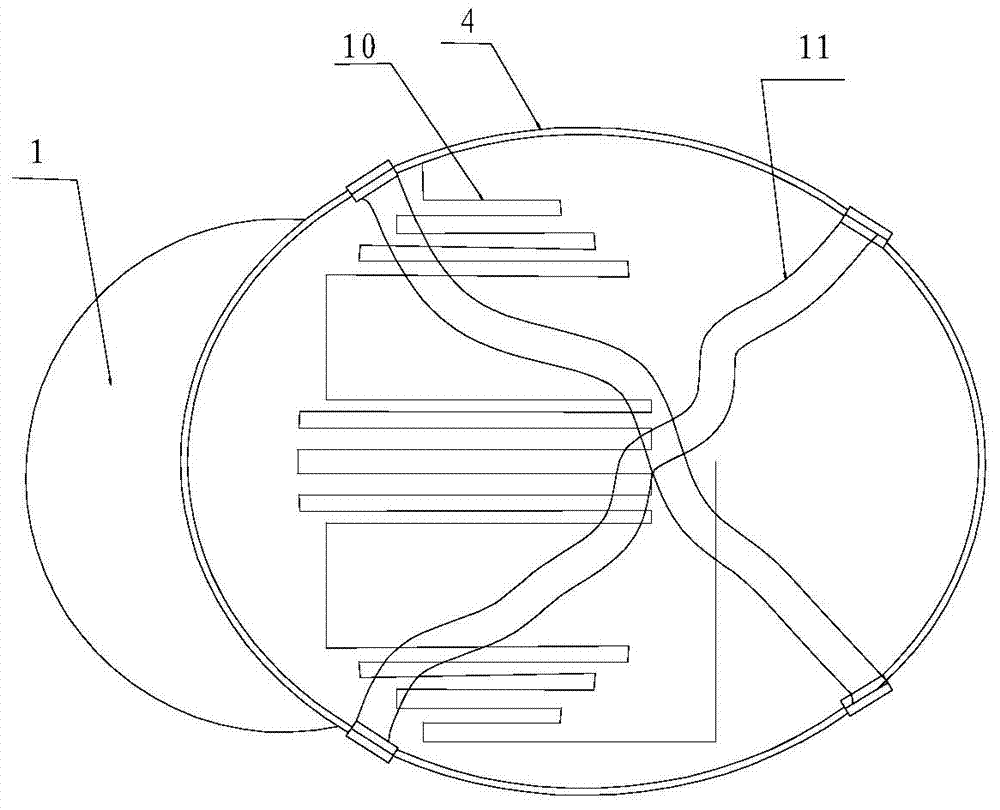

[0025] Such as figure 1 , figure 2 and image 3 As shown, it is a structural schematic diagram of the present invention. The working safety helmet with a refrigeration system of the present invention includes a cap shell 4 and a visor 1, and an air-conditioning and refrigeration system is installed on the cap shell 4.

[0026] The hat shell 4 and visor 1 are made of plastic composite insulating material, which is light in weight, high in strength and good in insulation performance; Fix the micro compressor 5 and the micro motor 7, the micro compressor 5 and the micro motor 7 are connected as one, light in weight and small in size. In recent years, the micro compressor technology has made great progress. The weight can be reduced to about 100 grams, and the volume can be reduced to only the size of the No. 5 battery. For a refrigeration system with a cooling capacit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com