A multi-point injection device

A material injection and multi-point technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of glue breaking, uneven glue dispensing, and glue leakage, etc., to ensure quality, uniformity, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

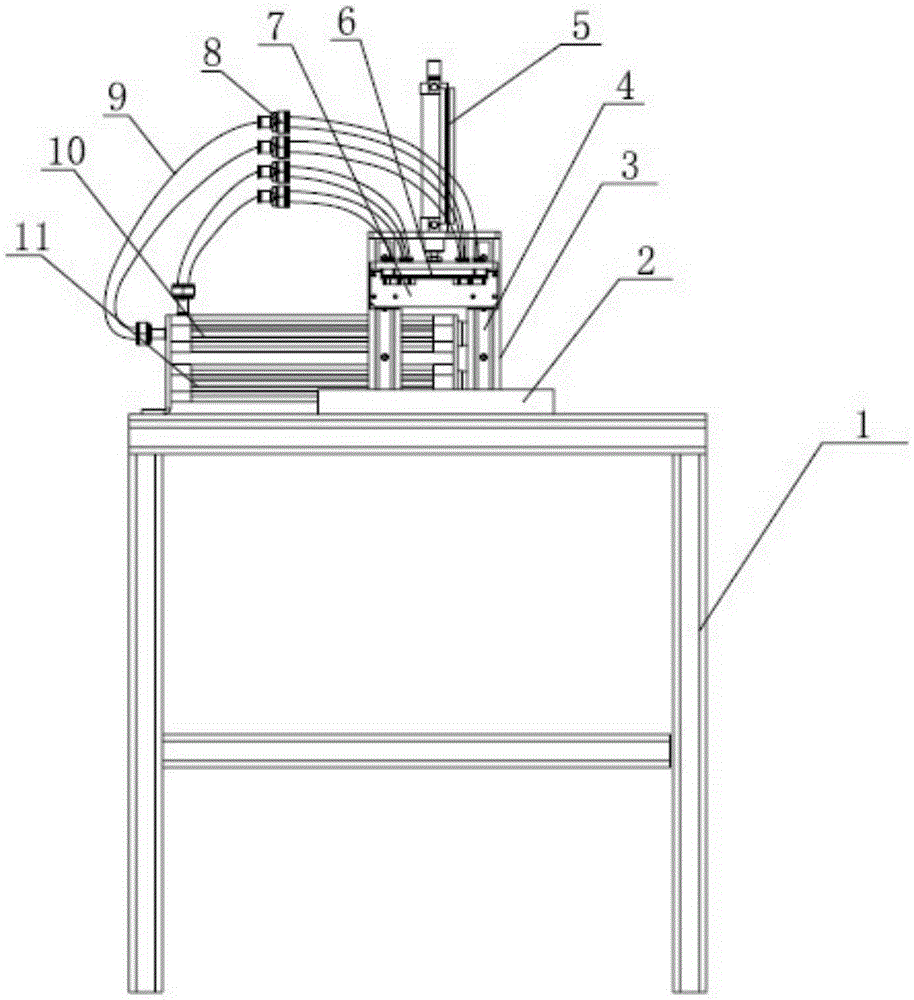

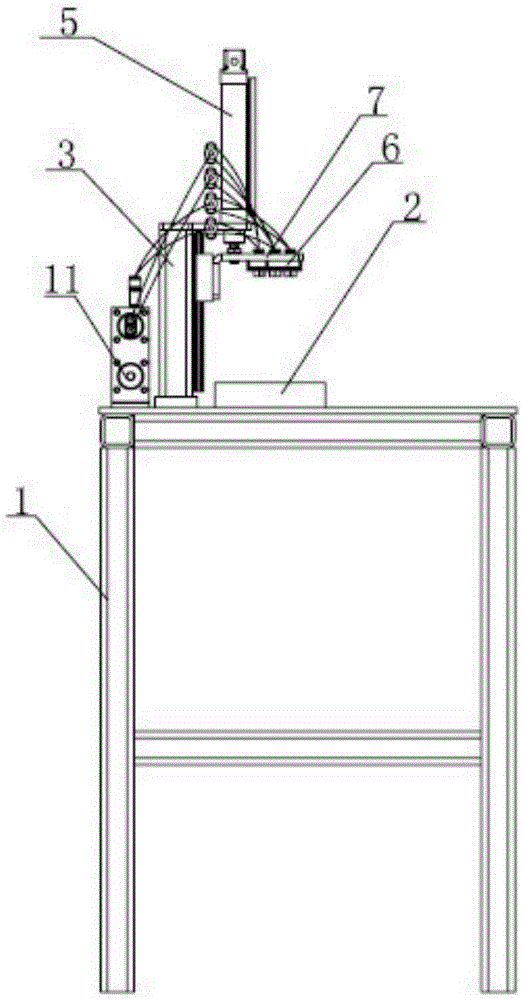

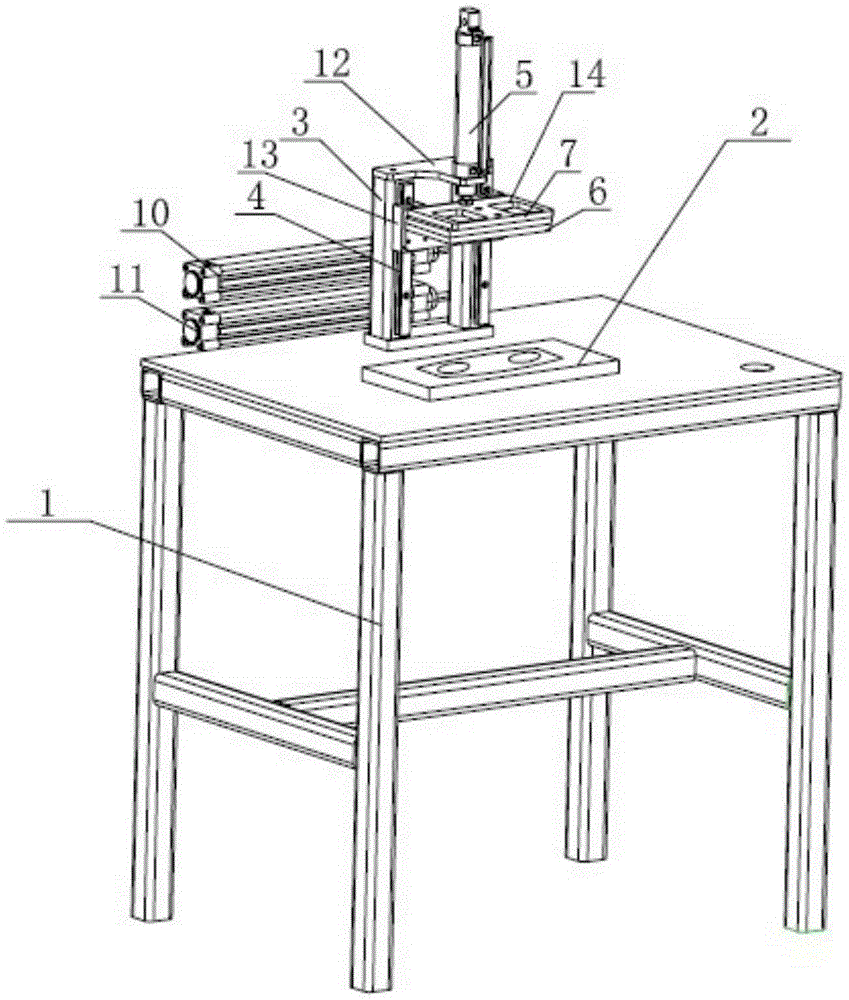

[0026] The inner diameter of the injection cylinder 10 is 32mm, and the length of the liquid material inside the cylinder is 300mm. There are 8 injection points on the product that needs to be injected, and the injection amount of each injection point is 2mm. 3 , 4 injection pipes 9 are passed out from the injection cylinder 10, respectively connected to the taps 8, and each tap 8 leads to two injection pipes 9, and a total of 8 injection pipes 9 are respectively connected to the injection guide plate The injection hole 63 on 61 is connected. When injecting glue, place the product on the special product positioning plate 2, and arrange the injection part of the product upwards, and then the cylinder I5 pushes the injection fixing plate 7 and the injection mold 6 to Move down until the lower injection plate 62 of the injection mold 6 sticks to the upper end surface of the product, and then the cylinder II11 works intermittently to drive the push piston of the injection cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com