Bolt limiting type suspension cushion assembly

A technology for suspending soft pads and bolts, which is applied in the direction of power plants, jet propulsion devices, internal combustion propulsion devices, etc., can solve the problems of easy tearing of rubber, short service life, and difficult rubber tearing, so as to prevent tearing and use Long life, the effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

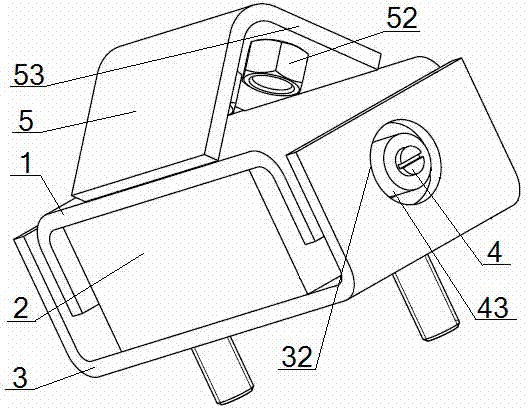

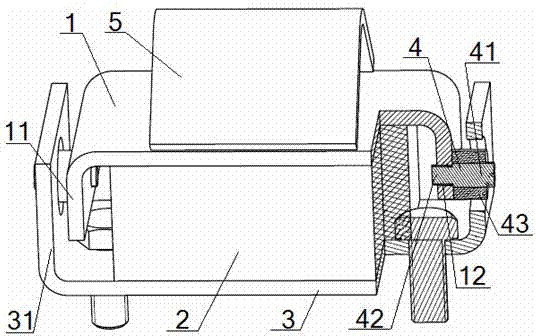

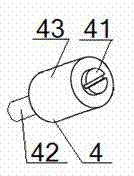

[0039] see figure 1 – Figure 4 , a bolt-limited suspension cushion assembly, including an upper frame 1, a vulcanized rubber 2 and a lower frame 3, the upper frame 1 is vulcanized with the lower frame 3 through the vulcanized rubber 2; the two sides of the upper frame 1 There are lower flanges 11, and upper flanges 31 are provided on both sides of the lower frame 3, and the two upper flanges 31 are arranged on the outer sides of the two lower flanges 11, and the lower flanges 11 are fixedly connected by the outer sides Position bolt 4 and its adjacent upper flange 31 limit fit; said limit bolt 4 includes a screw head 41 and a screw rod 42 connected to each other, the screw head 41 is cylindrical, and its top is provided with a word groove or a cross groove; Said screw 42 is threadedly matched with the threaded hole 12 in the middle part of the lower flange 11, and the outer cylindrical surface of the screw head 41 is limitedly matched with the inner wall of the limit hole 32...

Embodiment 2

[0041] Embodiment 2 is basically the same as Embodiment 1, except that the screw head 41 and the buffer rubber sleeve 43 are vulcanized as one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com