Special container with automatic alarm and liquid filling quantity setting functions for automobiles and using method of container

An automatic alarm and container technology, applied in the direction of containers, rigid containers, bottle/can parts, etc., can solve problems affecting product quality, employees drinking by mistake, etc., to improve employee satisfaction, reduce labor intensity, and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

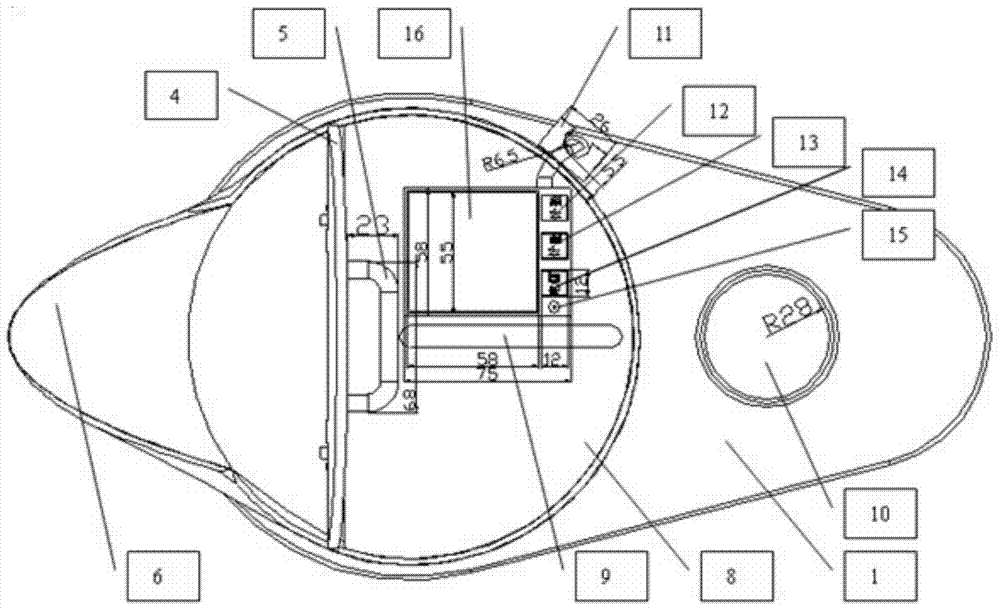

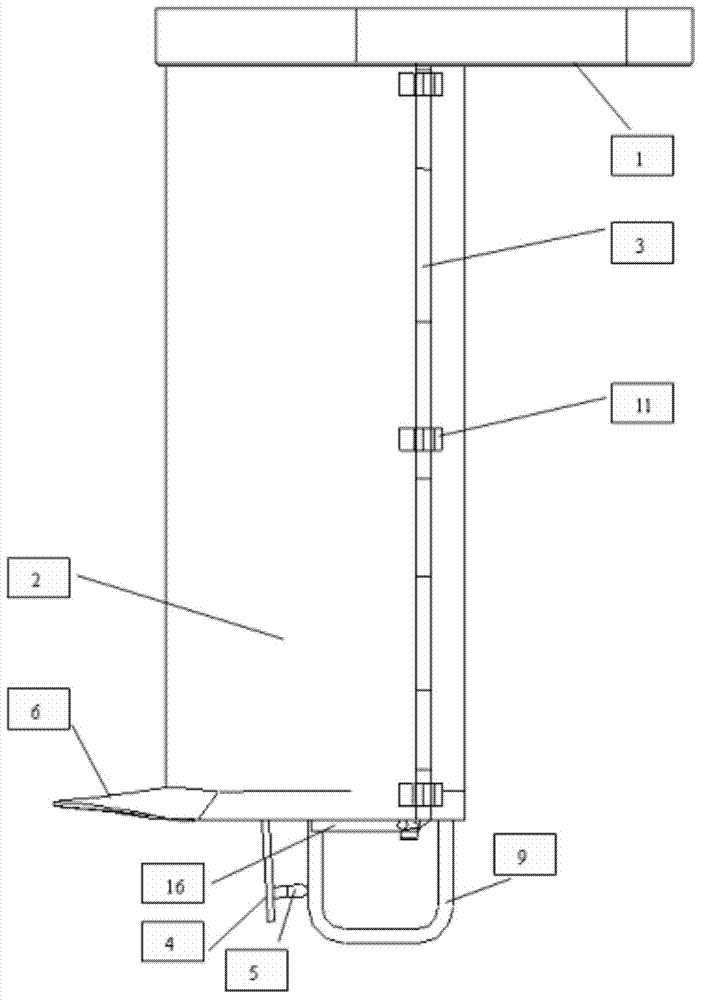

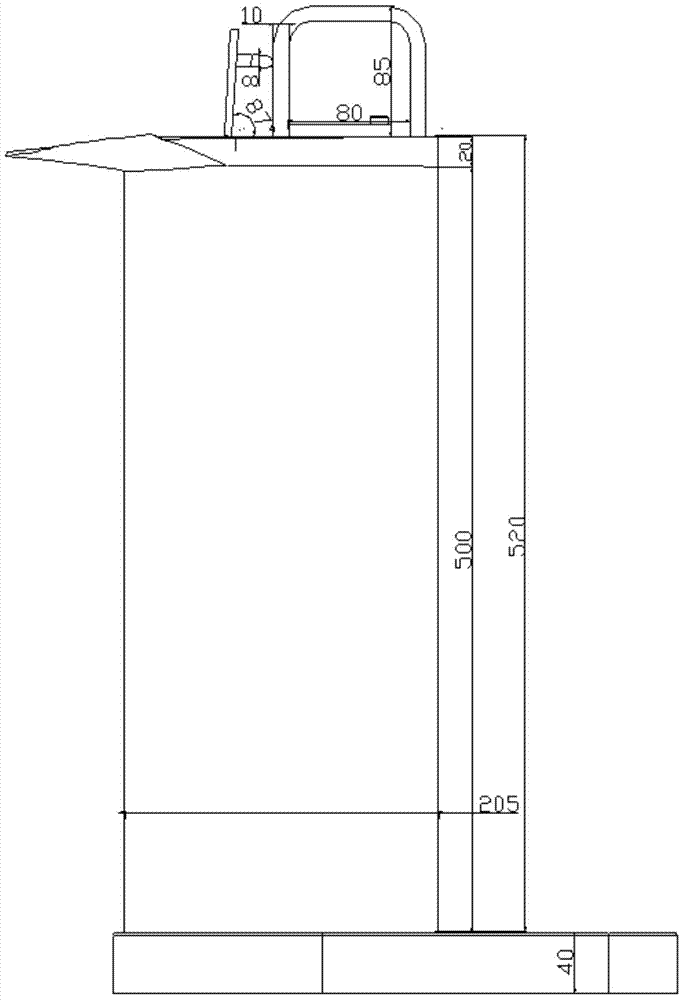

[0054] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

[0055]The product material of this container is high-density polyethylene, referred to as HDPE. The density is 0.941~0.965g / cubic centimeter. It is made of low-pressure polymerization, so it is also called low-pressure polyethylene. It is milky white, indicating less gloss. The film can be processed by blow molding and T-die extrusion. It is heat-resistant and steam-resistant, cold-resistant and freezing-resistant, moisture-proof, gas-proof, good insulation performance, and not easy to break, and its strength is twice that of LDPE. Raw material preparation, blow molding, injection molding, demoulding and trimming, waste crushing, drying, assembly, final inspection and warehousing.

[0056] 1. Requirements for the design size of the liquid filling container base:

[0057] The body is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com