Mobile rapid desulphurization equipment and natural gas desulphurization method

A desulfurization equipment, mobile technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with specific embodiment, this patent will be further described.

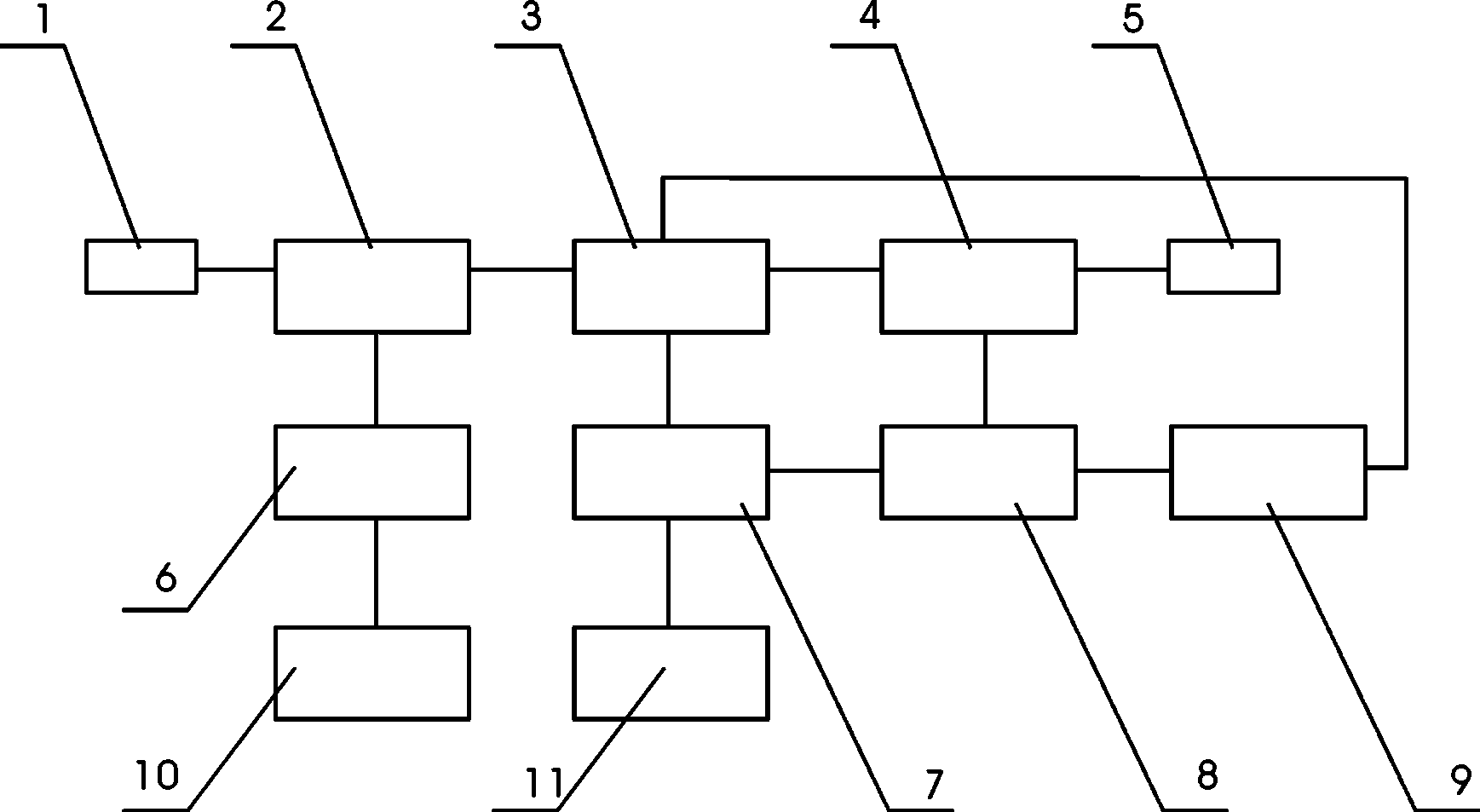

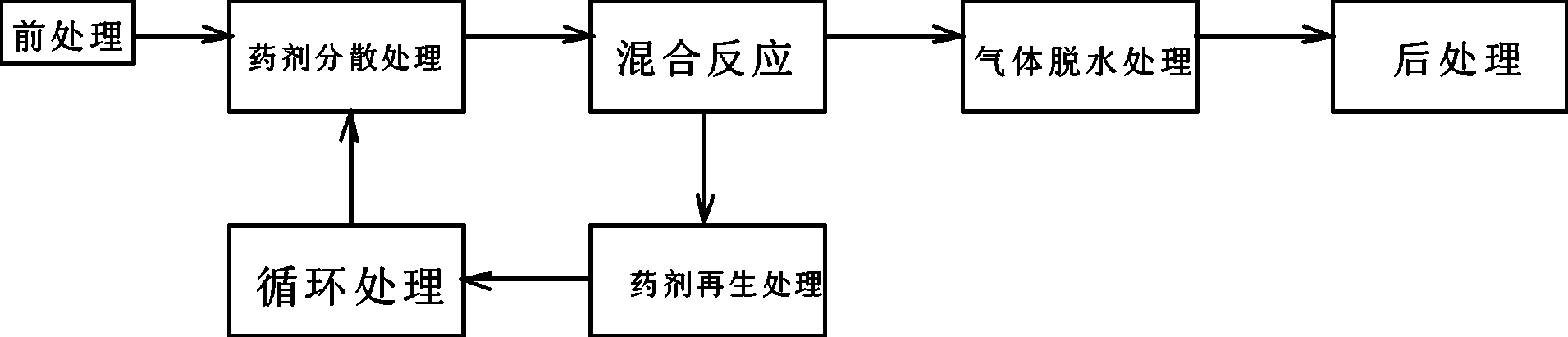

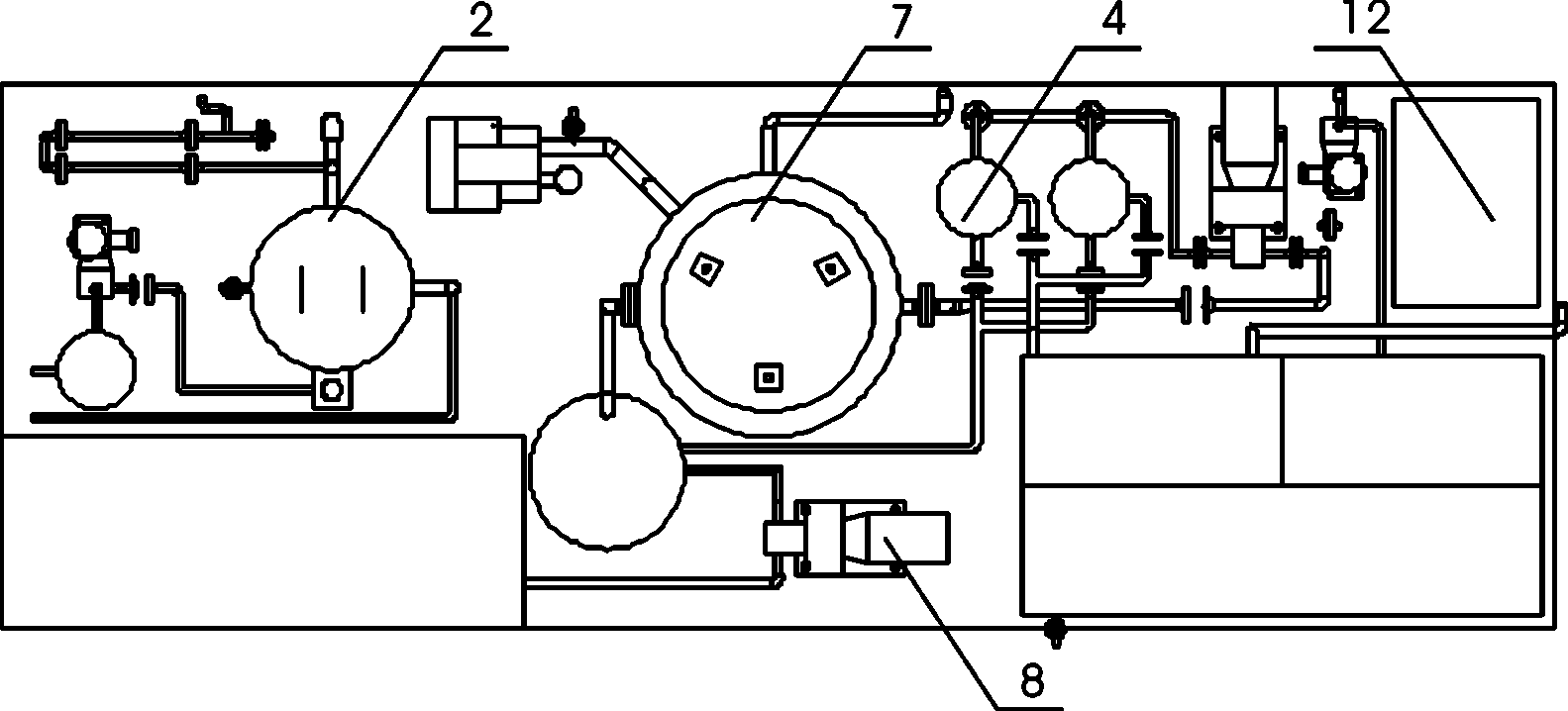

[0021] Mobile fast desulfurization equipment, composed of inlet pipe, separator, mixing reactor, filter, outlet pipe, oil-water separator, regeneration reactor, circulation device, chemical dispersion device, mixing reactor, recovery device, sulfur hydraulic filter , the inlet pipe is connected to the separator, the gas outlet of the separator is connected to the mixing reactor, the gas outlet of the mixing reactor is connected to the filter, the outlet of the filter is connected to the gas outlet pipe, an oil-water separator is set on the separator, and the oil-water separator is connected to the recovery The mixing reactor is connected to the regeneration reactor, and the regeneration reactor is connected to the circulation device and the sulfur hydraulic filter, the circulation device is connected to the filter and the medicament dispersing device at the same time, and the medicame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com