Rapeseed oil refining precipitation system

A technology of rapeseed oil and settling tank, which is applied in the direction of fat oil/fat refining, settling tank, feeding/discharging device of settling tank, etc. It can solve the problems of poor batch processing capacity, high labor intensity, low production efficiency, etc. , to achieve the effect of improving large-scale processing capacity, reducing operating labor intensity, and reducing production labor costs

Inactive Publication Date: 2014-02-12

SICHUAN DEYANG NIANFENG FOOD

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the traditional sedimentation system has a simple structure, poor batch processing capacity, and time-consuming cleaning of the oil foot after sedimentation, so the labor intensity during production is high and the production efficiency is low.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0011] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

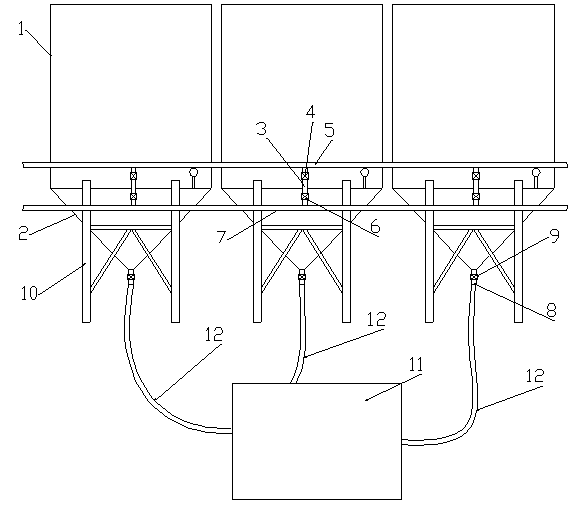

The invention discloses a rapeseed oil refining precipitation system which comprises a plurality of precipitation tanks arranged together, an oil inlet pipe and an oil outlet pipe communicated with the precipitation tanks, and an oil residue recovery pool disposed on the ground; the lower end of each precipitation tank is provided with a residue discharging port and a control valve; the residue discharging port is communicated with the oil residue recovery pool through a flexible pipe. According to the rapeseed oil refining precipitation system of the invention, the plurality of precipitation tanks are arranged together, and are parallelly connected on the same oil inlet pipe and the oil outlet pipe, so unified oil charging, oil discharging, and oil residue discharging control is realized, which not only improves the mass processing capability of the rapeseed oil precipitation procedure, but also improves working efficiency, reduces operation labor intensity, and decreases production manpower cost; oil residues from each precipitation tank are collected and stored through the oil residue recovery pool, which is simple in operation and facilitates subsequent oil residue processing.

Description

technical field [0001] The invention relates to a rapeseed oil refining equipment, in particular to a rapeseed oil refining precipitation system. Background technique [0002] When refining the pressed rapeseed oil, it is necessary to carry out a long-term precipitation treatment on the rapeseed oil to separate out the oil residue and improve the purity of the rapeseed oil. However, the traditional sedimentation system has a simple structure, poor batch processing capacity, and time-consuming cleaning of the oil foot after sedimentation, so the labor intensity during production is high and the production efficiency is low. Contents of the invention [0003] The technical problem to be solved by the present invention is to provide a rapeseed oil refining and sedimentation system with high degree of automation, strong batch processing capability and convenient operation. [0004] In order to solve the above technical problems, the present invention adopts the following tech...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C11B3/00B01D21/02B01D21/24

Inventor 王安体王长严

Owner SICHUAN DEYANG NIANFENG FOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com