Building block floor

A technology for flooring and building blocks, applied in the field of white steel welding and woodworking furniture, can solve the problems of inconvenient maintenance, disassembly, poor thermal conductivity, poor comfort, etc., and achieve the effect of easy replacement, convenient maintenance, and material and labor saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

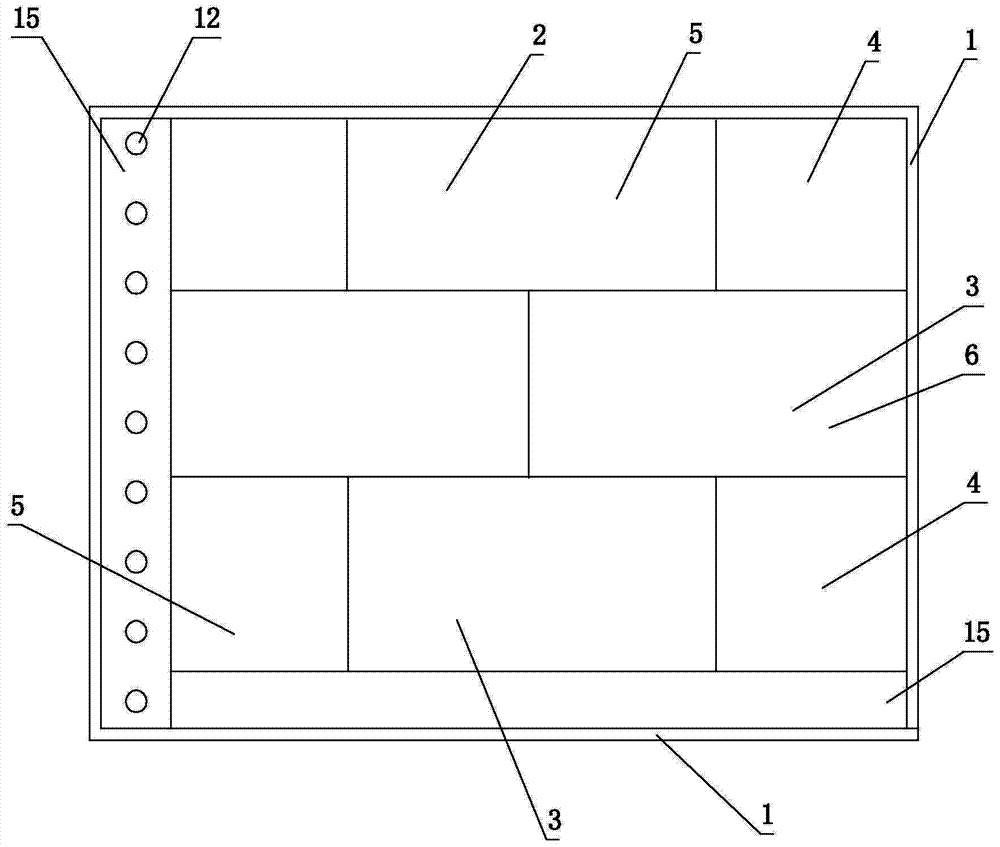

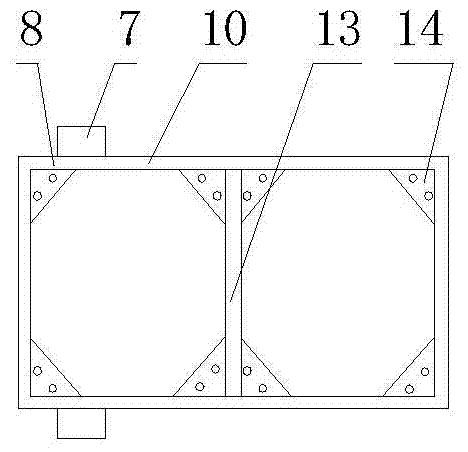

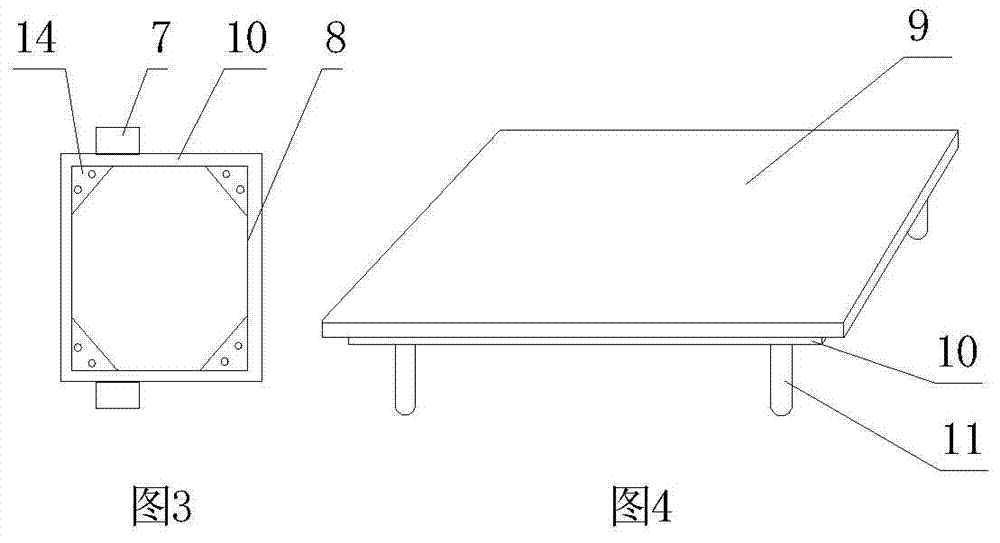

[0023] Such as Figure 1 to Figure 5 As shown, a building block floor includes a closed fixed frame 1 fixed on the wall, and several unit boards 2 are arranged in the fixed frame 1, and the upper surface of the fixed frame 1 and the unit board 2 are in the same plane; The unit board 2 is divided into a long board 3 and a short board 4, and the length of the short board 4 is half of the length of the long board 3; The two ends are short boards 4, and the long boards 3 are arranged between the short boards 4. The width of the long and short board rows 5 is the same as that of the long boards 3; The width is the same; two long boards 3 are arranged horizontally to form a long board row 6, and the width of the long board row 6 is the same as the width of the long board 3; The boards 3 and the long boards 3 of the long board rows 6 are v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com