Device for realizing incompressible fluid critical flow by applying mechanical choking principle

A technology of compressing fluid and critical flow, applied in the direction of fluid flow, mechanical equipment, etc., can solve the problems affecting flow control and measurement accuracy, no shielding effect, poor safety performance, etc., to achieve small energy loss, obvious effect, and reduce erosion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

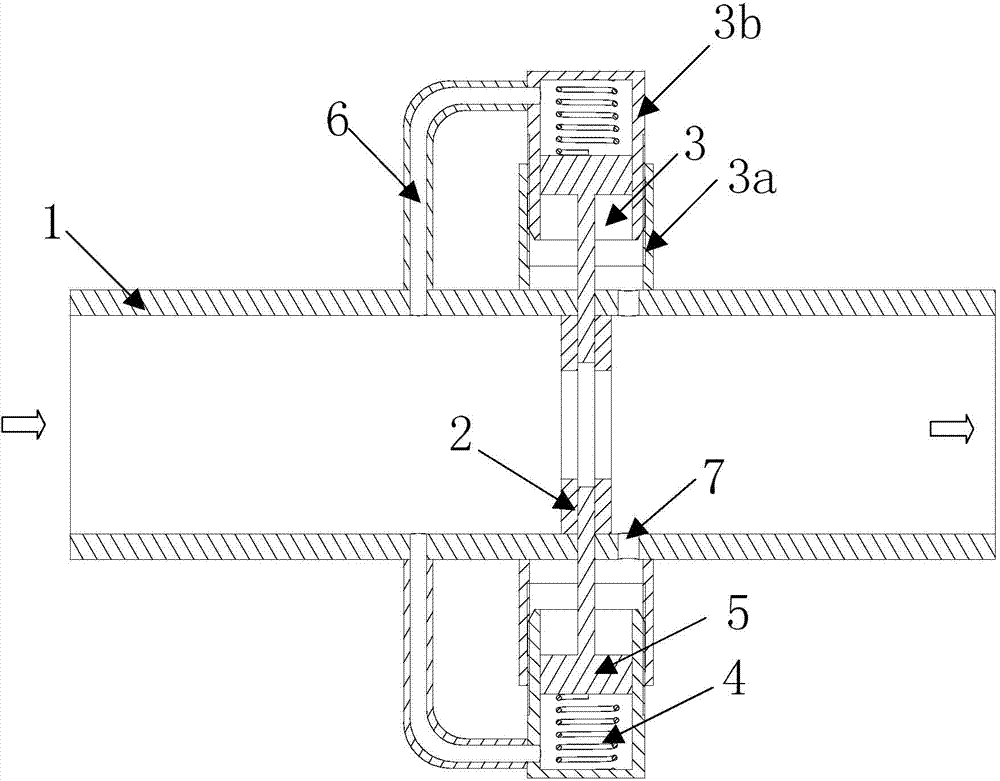

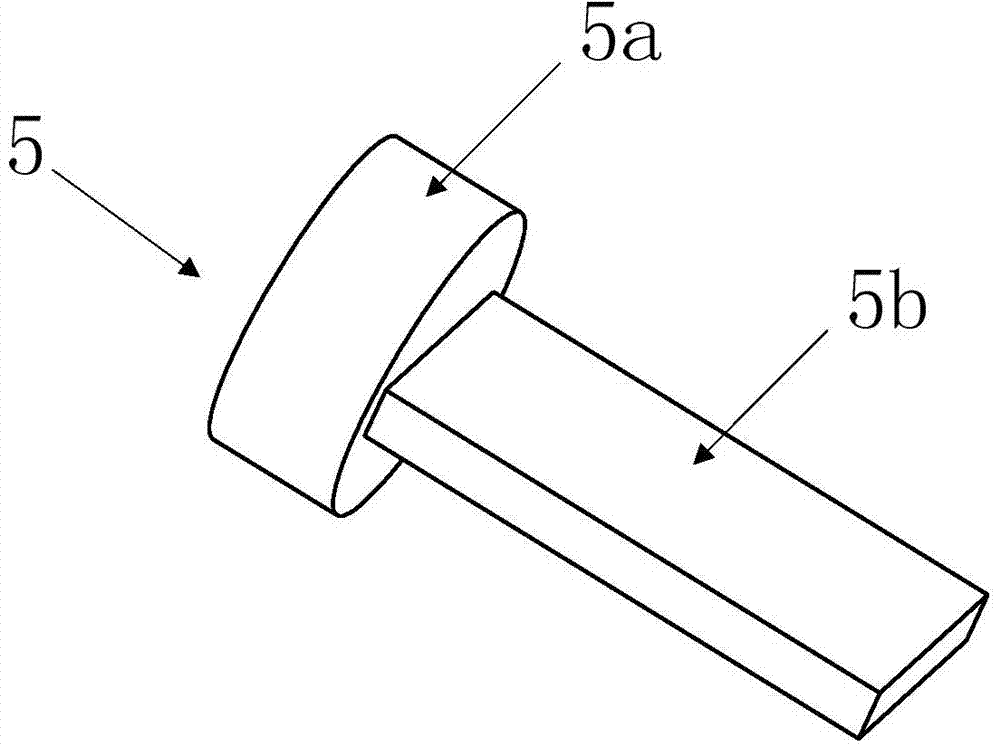

[0031] like figure 1 As shown, the present embodiment is a device for realizing the critical flow of incompressible fluid by applying the principle of mechanical choking, including a cylindrical shell 1, and a special-shaped orifice plate 2 is coaxially fixed in the cylindrical shell 1, and the two can Use any kind of fixed connection such as welding or screw connection. Two spring-float action chambers 3 are arranged symmetrically up and down at the position corresponding to the special-shaped orifice plate 2 outside the cylindrical shell 1, and a connected high-precision linear spring 4 and float 5 are arranged in the spring-float action chamber 3 , the upper cavity of the spring-float action chamber 3 communicates with the upstream pipeline of the special-shaped orifice plate 2 through the high-pressure guide channel 6, and the lower cavity communicates with the downstream pipeline of the special-shaped orifice plate 2 through the low-pressure guide hole 7. The high-pressu...

Embodiment 2

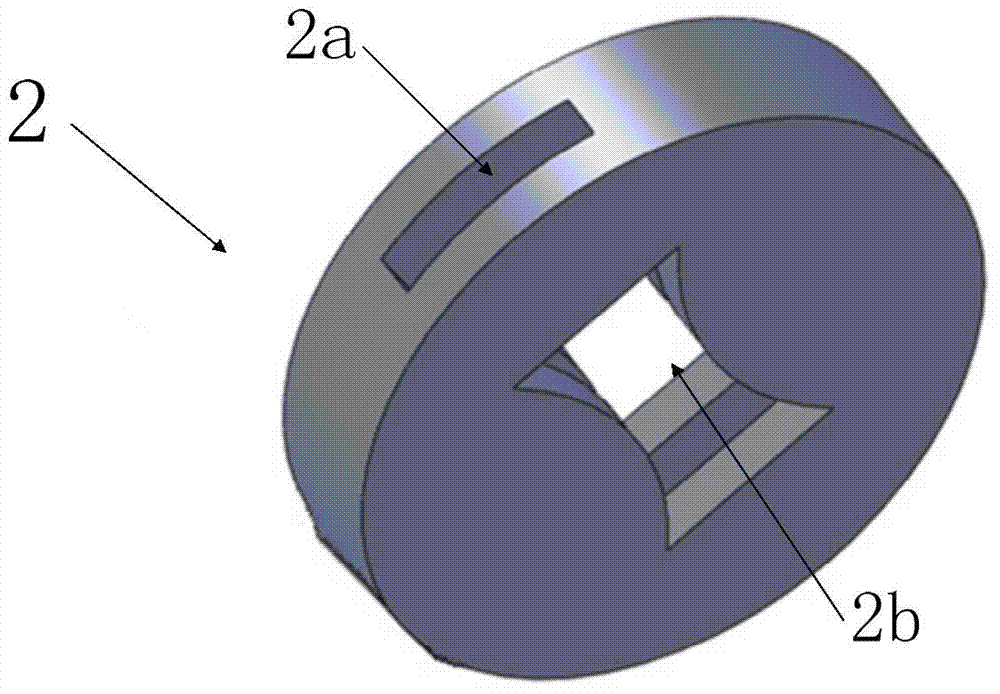

[0042] like Image 6 As shown, it is another structural form of the present invention that applies the principle of mechanical choking to realize the critical flow of incompressible fluid, wherein there is one spring-float action chamber 3, which is arranged on one side of the cylindrical shell 1, and the special-shaped orifice plate 2 A radial non-penetrating baffle guide hole 2a is opened at its axial middle position, and the section of the inner hole 2b corresponding to the baffle guide hole 2a is a quadrilateral with a specific shape, and the quadrilateral is an axisymmetric figure. The equation of its effective control shape line S is (2):

[0043] y = Q 4 α 2 ρk / A 0 ( m - x ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com